26

Geotechnical News • June 2017

THE GROUT LINE

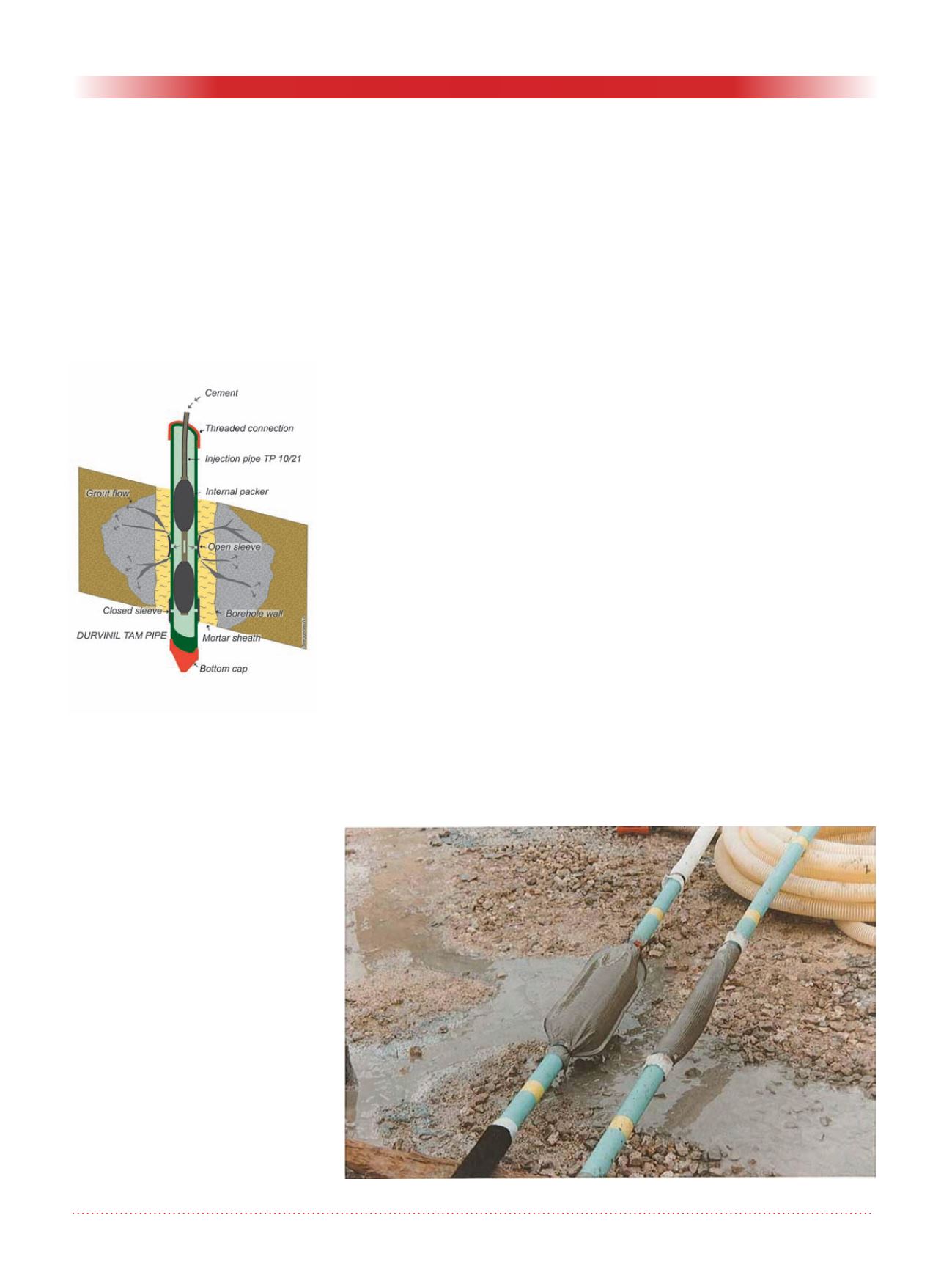

hydraulic with expansion joint). The

injection mixture opens the valve and

spreads the grout into the surrounding

soil. After grouting, the valve closes,

preventing the injected material from

returning into the pipe. Once the pipe

has been washed inside, the valves are

ready to be used eventually for other

subsequent grouting operations.

There are many advantages to this

method. One of them is that the injec-

tion can be carried out in more than

one stage and, if necessary, using dif-

ferent cement based mixtures.

One of the typically employed grout-

ing processes is

Permeation grouting

,

which consists of filling the natural

voids in the soil with a mixture, substi-

tuting the in-situ fluid (normally air or

water). The result is a reduction of the

hydraulic conductivity and an increase

in the mechanical characteristic of

the soil. Cements, chemical mixtures

and resins reinforce the soil structure,

improving the strength and the elastic

modulus of the treated ground. The

granular composition of the soil also

plays a fundamental role in the success

of the permeation grouting: the finer

the dimension of the soil grains and

the higher the dis-uniformity degree

(U= D

60

/D

10

), the lower the volume of

the voids. So basically it is important

that in the first phase of the grouting

design, a detailed investigation cam-

paign including soil coring is planned,

in order to obtain the granulometric

sieve from samples of the soil layers

where the treatment shall be carried

out.

On the other hand, the capability of

a grout mix to permeate the soil is a

function of its composition. The rheol-

ogy study of the mixtures allows for

definition of this parameter.

In order to achieve a good permeation

grouting homogeneity, cement mixes

are stabilized by adding a filler (for

example bentonite) that helps to main-

tain in suspension the cement grains.

The use of fillers normally increases

the viscosity of the mixture; the use

of polymeric-based additives allows

viscosity and stability to reach optimal

values.

As a matter of fact, an accurate set of

preliminary tests has to be foreseen

before starting permeation grouting

work, in order to define the correct

mixture to be used for the grout and

to provide the benchmark values of

its rheological parameters. The latter

will be considered during the on-site

work in progress controls. The use of

sleeved pipes brings a series of advan-

tages to permeation grouting:

• it allows for the injection of the

proper grout quantities, in a con-

trolled way, in the different zones

of the soil mass to be treated;

• for each sleeve it is possible to

record the operative parameters

(pressure and flow rate) during

the injection process, obtaining

the “story” of each grouting and

allowing the evaluation of the pa-

rameters for the following steps;

• it is possible, if necessary, to inject

additional quantities of grout in

further stages;

• it allows for the injection of dif-

ferent kinds of mixtures from the

same sleeve, for example follow-

ing an order of growing penetrabil-

ity.

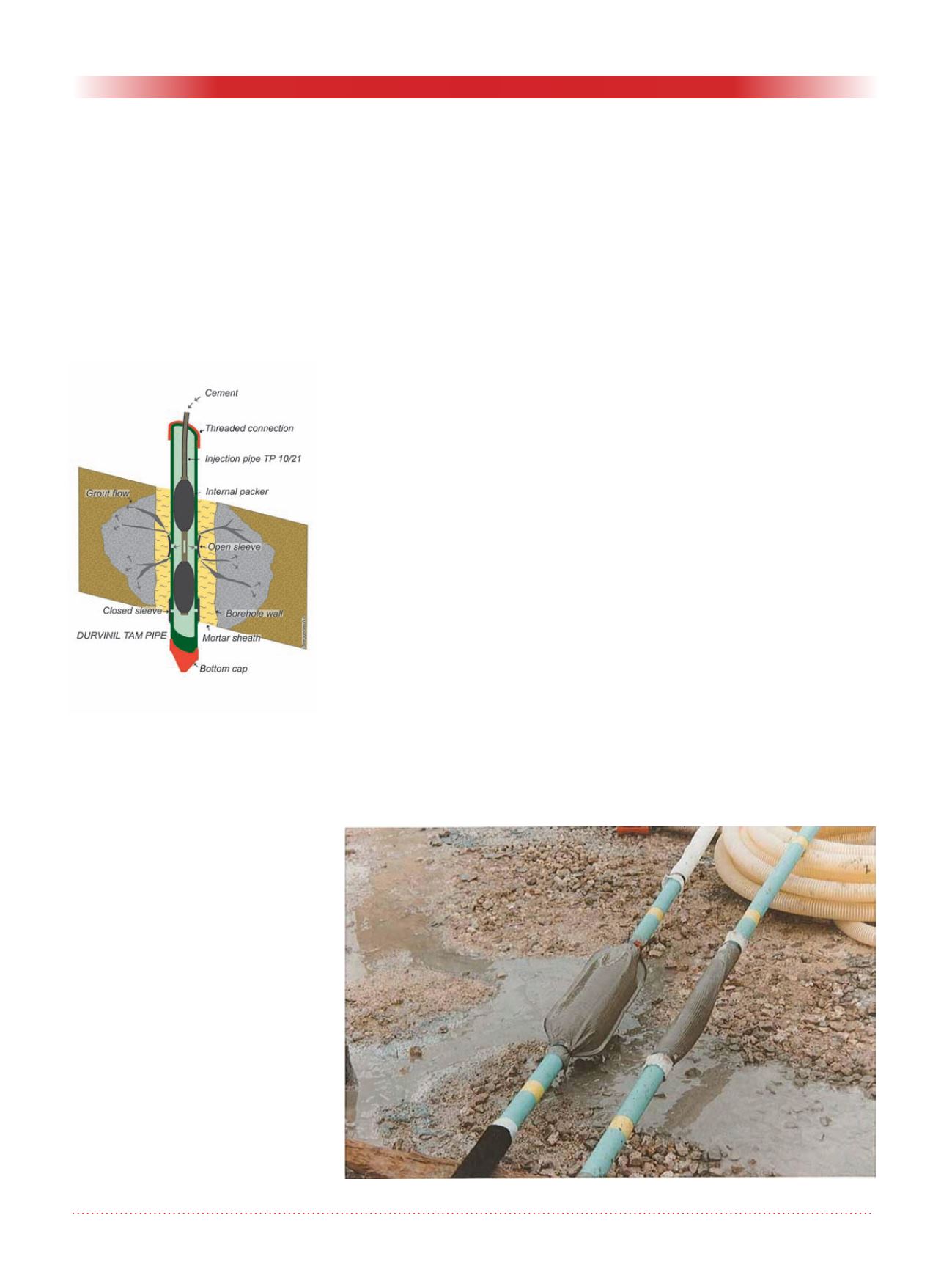

The use of sleeved pipes, often

coupled with a polypropylene bag

(Fig.3), allows for the reduction of the

number of drillings required. This way

the injection process is faster, without

any influence on the type of mixture to

be injected and/or on the parameters to

be used.

Grouting is not only required to

improve the mechanical character-

istics. It has also been used in the

reduction of the mechanical prop-

Figure 2. Grouting injection through

a sleeved grouting pipe.

Figure 3. High tenacity polypropilene bags.