Geotechnical News • September 2019

23

GEO-INTEREST

The Phoenix Ground Improvement Machine

Bill Hodge

My purpose in writing this article is to

bring to the attention of the geotech-

nical fraternity the fact that we now

have at our disposal a tool which can

turn loose saturated granular materi-

als

into highly competent

foundations.

Using this hardware, materials such as

sands, silts, and rock flour (slimes) can

be compacted into a highly dense and

dilative aggregation at depths of up to

about 20m below ground level. Field

records from three different sites are

presented below to substantiate this

claim. It is by combining into a single

poker both vibration and water drain-

age that this is accomplished.

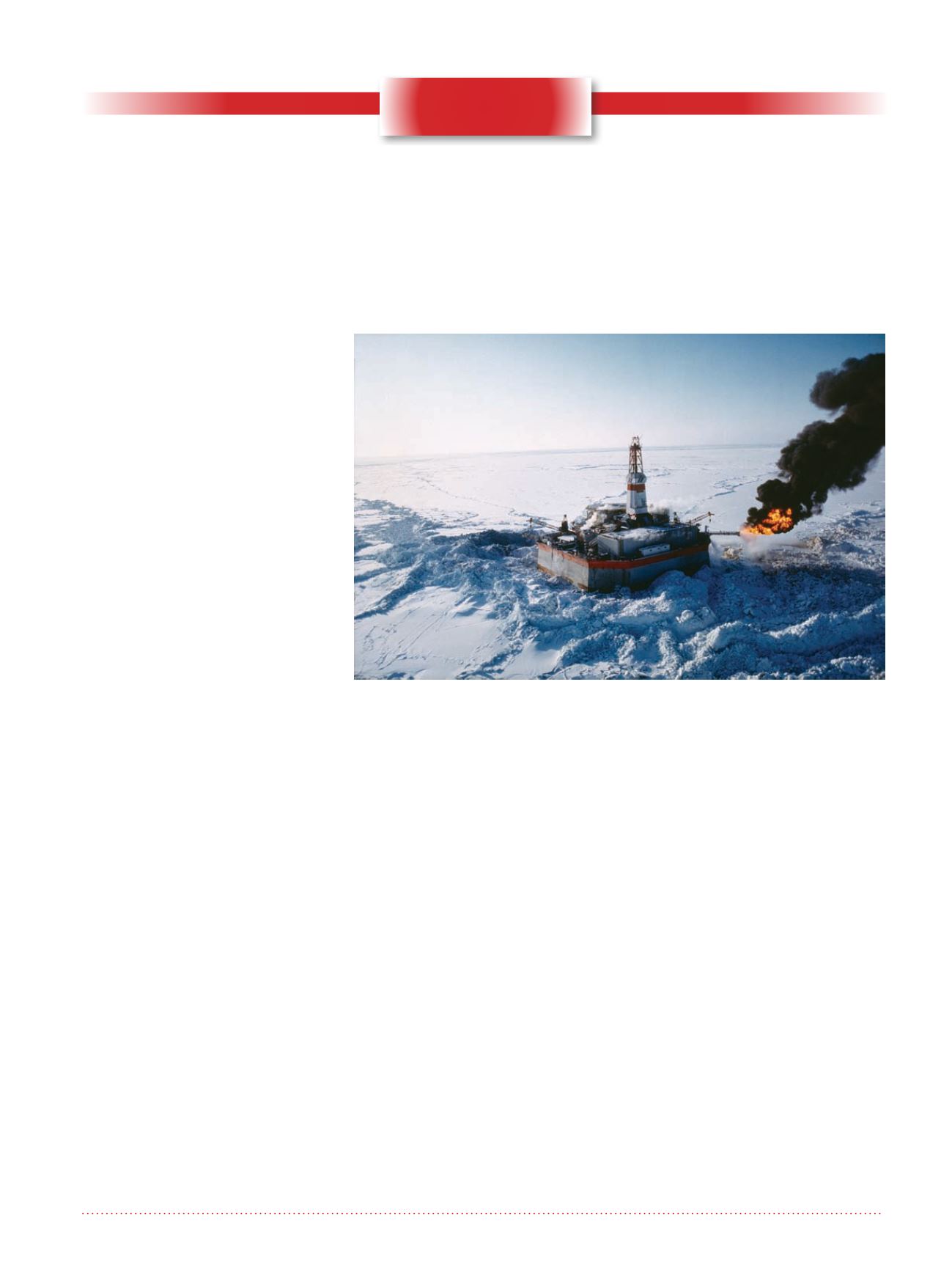

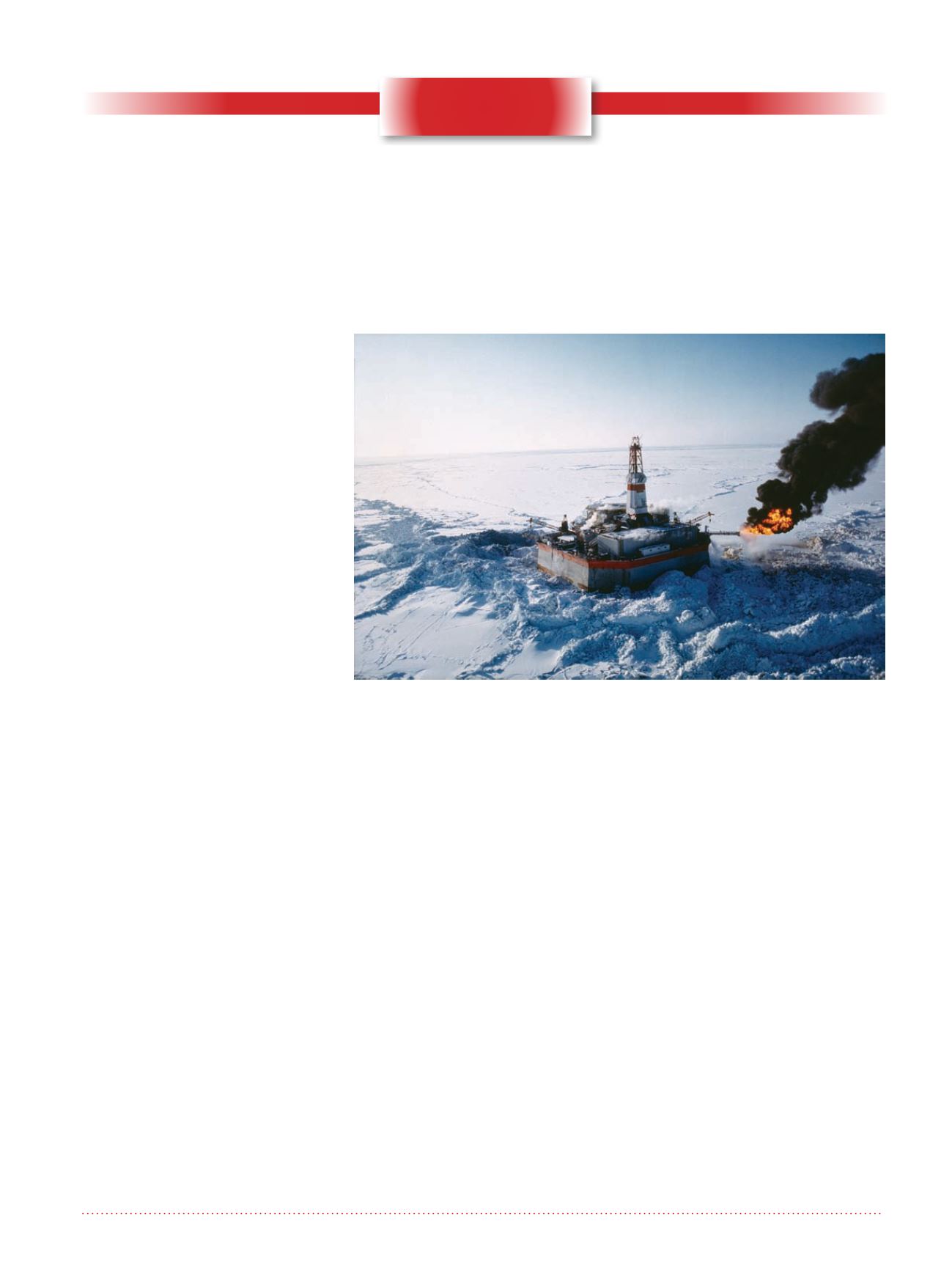

During the 1980s the petrochemi-

cal industry was anxious to tap into

the Amauligak oil fields beneath the

Mackenzie Delta in the Canadian

offshore Arctic.

Gulf Canada Resources [

GCR

] was

the oil company who initially engaged

me to see if there was a sand island

solution to getting their rigs into

deeper water. Before finishing that

work

GCR

made a decision to switch

their focus to a hybrid steel vessel

called the Molikpaq and asked me

to attend to the geotechnical side of

things. It consisted of a 70m square

annular hull with an enlarged moon

pool into which sandfills would be

dredged; the idea being that the plat-

form would gain its lateral stability

by virtue of the frictional resistance

between the underlying deltaic sand

and that within the open-bottomed

moon pool.

The design criteria involved a horizon-

tally applied ice loading (70,000 ton,

pulsating monotonically at 2Hz), see

Fig 1. Because of this my main pre-

condition for the vessel’s deployment

was that the sandfill be densified to

prevent subsequent liquefaction of the

core. This was an unpopular require-

ment as it added a time consuming

complication. As it turned out, unbe-

knownst to me, the Molikpaq went to

work for a couple of years without its

core having been densified. Appar-

ently this was on the advice of a third

party who based his judgement on

centrifuge model testing. That is until

1986 when the core did in fact liquefy

under ice-loading while the platform

was drilling on location. Then

GCR

asked Phoenix Engineering Ltd [

PEL

]

if we could fix it.

Restabilization of Molikpaq

Blast densification was an obvi-

ous option. But detonating multiple

charges of TNT inside the core of an

offshore platform while it was drilling

into an oil field cause some safety

and environmental concerns with the

regulating authority, Canadian Oil and

Gas Lands Administration [

COGLA

].

So while licensing discussions went

on

PEL

looked for a mechanical

solution. Since there was only 2.5m

(11ft) of height between the surface of

the sandfill and the underside of the

platform’s steel deck (see Fig 2), the

standard deep compaction pokers such

as Vibroflots were ruled out.

It was then that the idea of the vibro-

drain, hereinafter referred to as the

Phoenix Machine [

PM

], occurred to

me. By simply combining the ben-

efits of the seepage forces (Ref 1) we

knew about from our earlier research

at the hydraulic laboratories of NRC

in Ottawa had examined at NRC with

some sort of vibrator seemed to be

worth trying; vibration being the best

approach to improving the density of

granular (non-cohesive) loose materi-

als. The mechanical device we came

up with to produce vibrations was an

eccentric weight rotated by a custom

Figure 1: Molikpaq under ice attack.