24

Geotechnical News • September 2019

GEO-INTEREST

designed air-vane motor. The drainage

element which was attached above

the vibrator consisted of a structurally

supported Johnson Well Screen. The

exhaust from the air motor was used to

blow seepage water out of the sys-

tem. Both elements measured about

1.5m (5ft) in length and were 190mm

(7½”) outside diameter. The deploy-

ment method involved pushing these

elements and similarly sized extension

pipes into the ground using a drill rig.

Then, when the assembly reached the

required depth to be densified, the air

motor was activated and the string

gradually withdrawn to the surface

again.

COGLA

preference was for the

PM

idea, whereas

GCR

wanted to use

blasting because it could be done

more quickly. It was during this

period of hesitation that

PEL

built a

prototype of the

PM

described above

and field tested it on the ship-impact

sand berm protecting the north pier of

Annacis bridge

in Vancouver.

The results were

good.

In the event, we

mobilized what

was necessary

to perform the

work using either

explosives or

vibro-drainage.

By then

COGLA

had been talked

into the blast-

ing option and

therefore that is

how the work

began, all going

smoothly until

instrumenta-

tion showed

that vibrations

in some steel

members were

exceeding their

structural limit

(13”/s) as soon

as charges were

detonated within 3.7m (12ft) of the

core walls. That prohibition meant

the sandfill most vulnerable to the

effects of ice pounding would be left

untreated. It was at this stage

GCR

asked us to deploy the

PM

to fin-

ish the densification job. This extra

work went without a hitch, with large

volumes of seepage water being dis-

charged from the machine. At the few

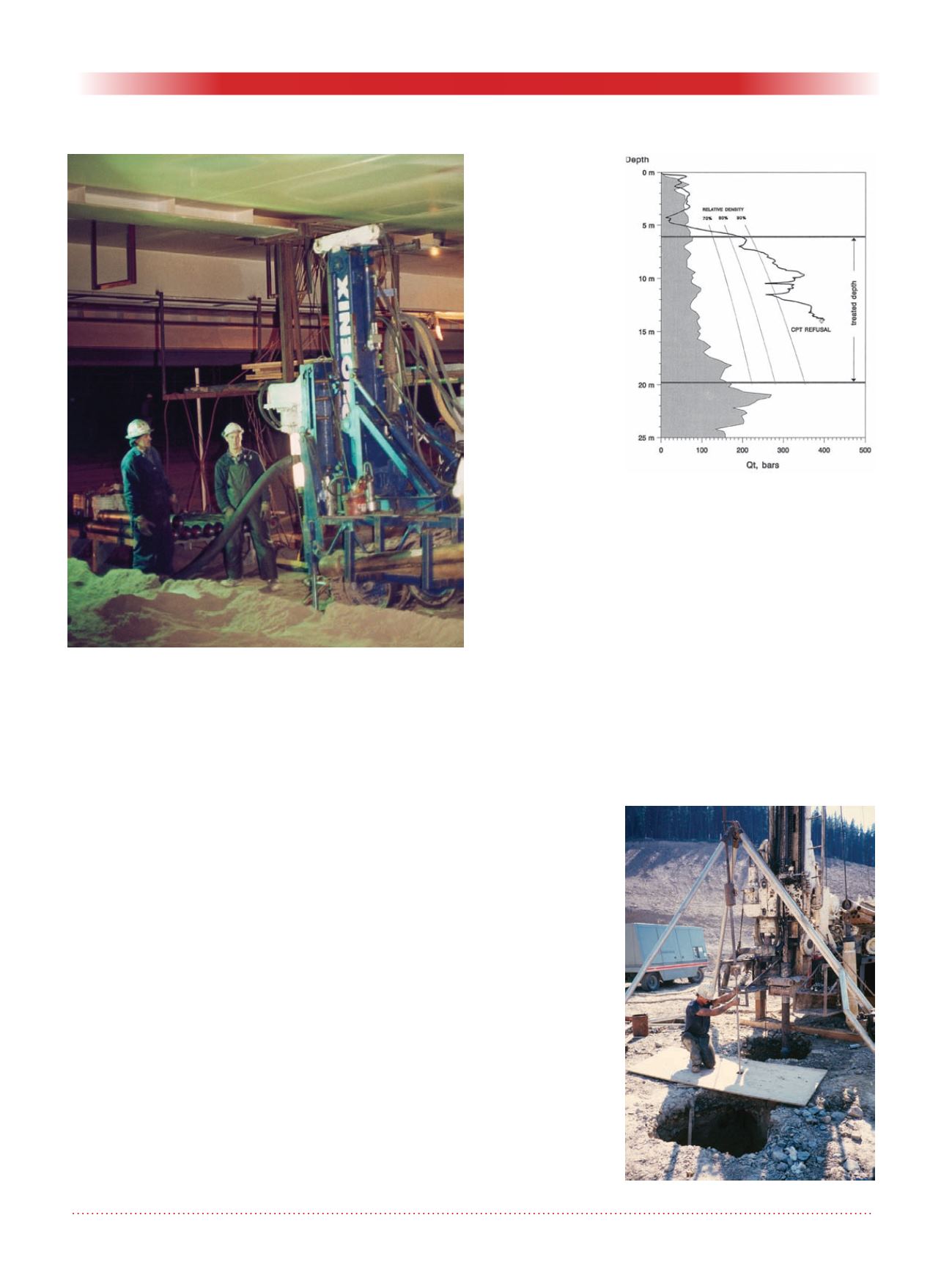

locations where CPT probes made a

direct hit on the top, buried 7m (23ft)

down, of one of the sand columns

created by the

PM

the results showed

relative densities generally exceeding

90% (Ref 3). One of these traces is

shown in Fig 3, where the background

shaded area shows the condition

achieved by blasting.

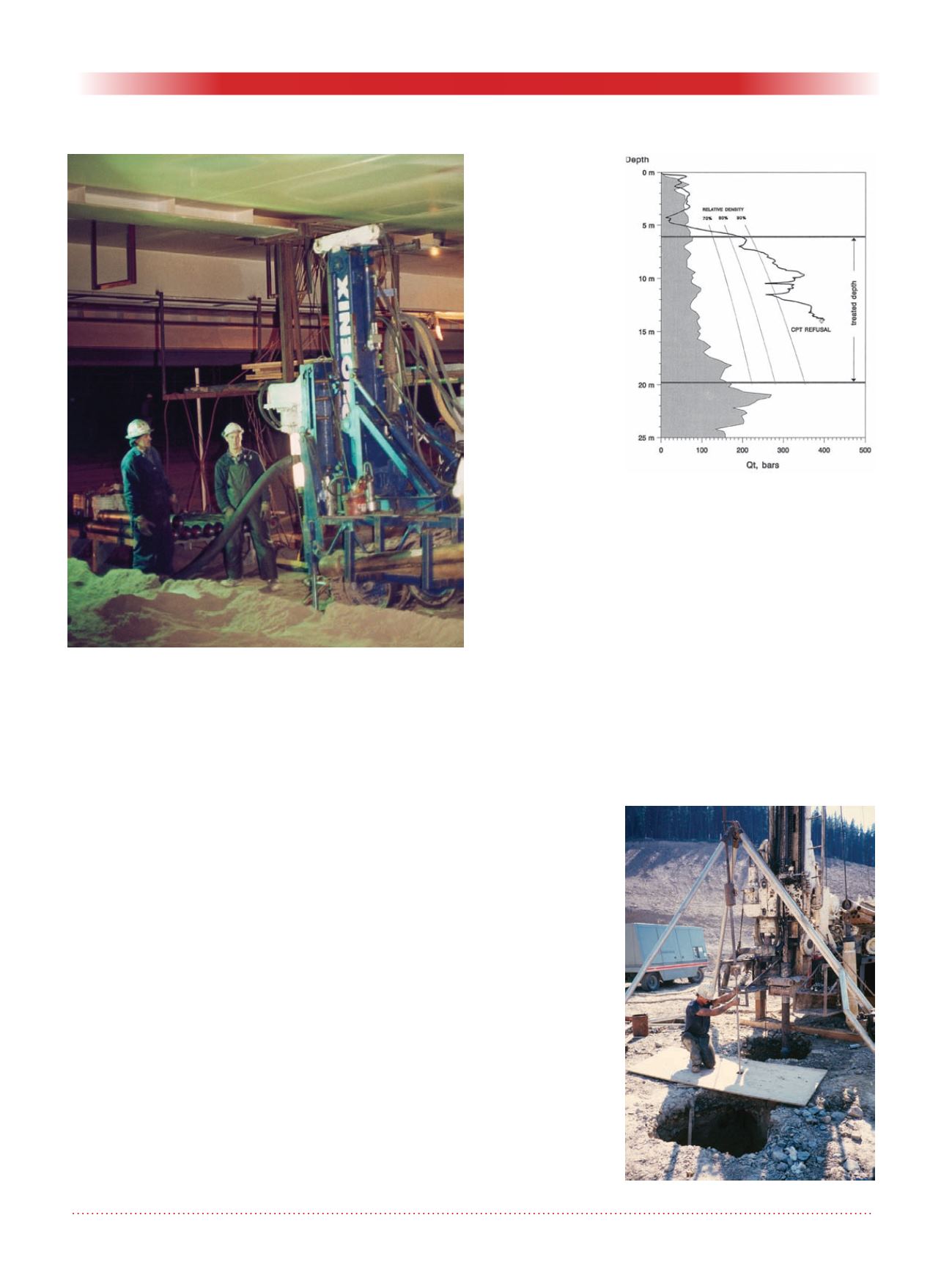

Black Dome Mine

During our field work on the upstream

face of the tailings dam at the Black

Dome goldmine in the Chilcotin area

of BC we observed something new.

Cylindrical holes appeared around

each location at which the

PM

was

activated, see Fig 4.

The tailings grind was 95% passing the

#200 sieve and accordingly its perme-

ability was quite low; in consequence,

there was very little seepage water

discharge. It is a geotechnical fact that

the quantity of flow is dependent upon

permeability, whereas the magnitude

of seepage forces is not. Therefore, the

amount of water discharge at ground

level is no indicator of the effective-

ness of the

PM

at depth.

Figure 3: CPT trace of PM results at

Molikpaq.

Figure 4: Craters at Black Dome.

Figure 2: Work space under Molikpaq deck.