26

Geotechnical News • September 2019

GEO-INTEREST

Improvements in the

PM

’s

design

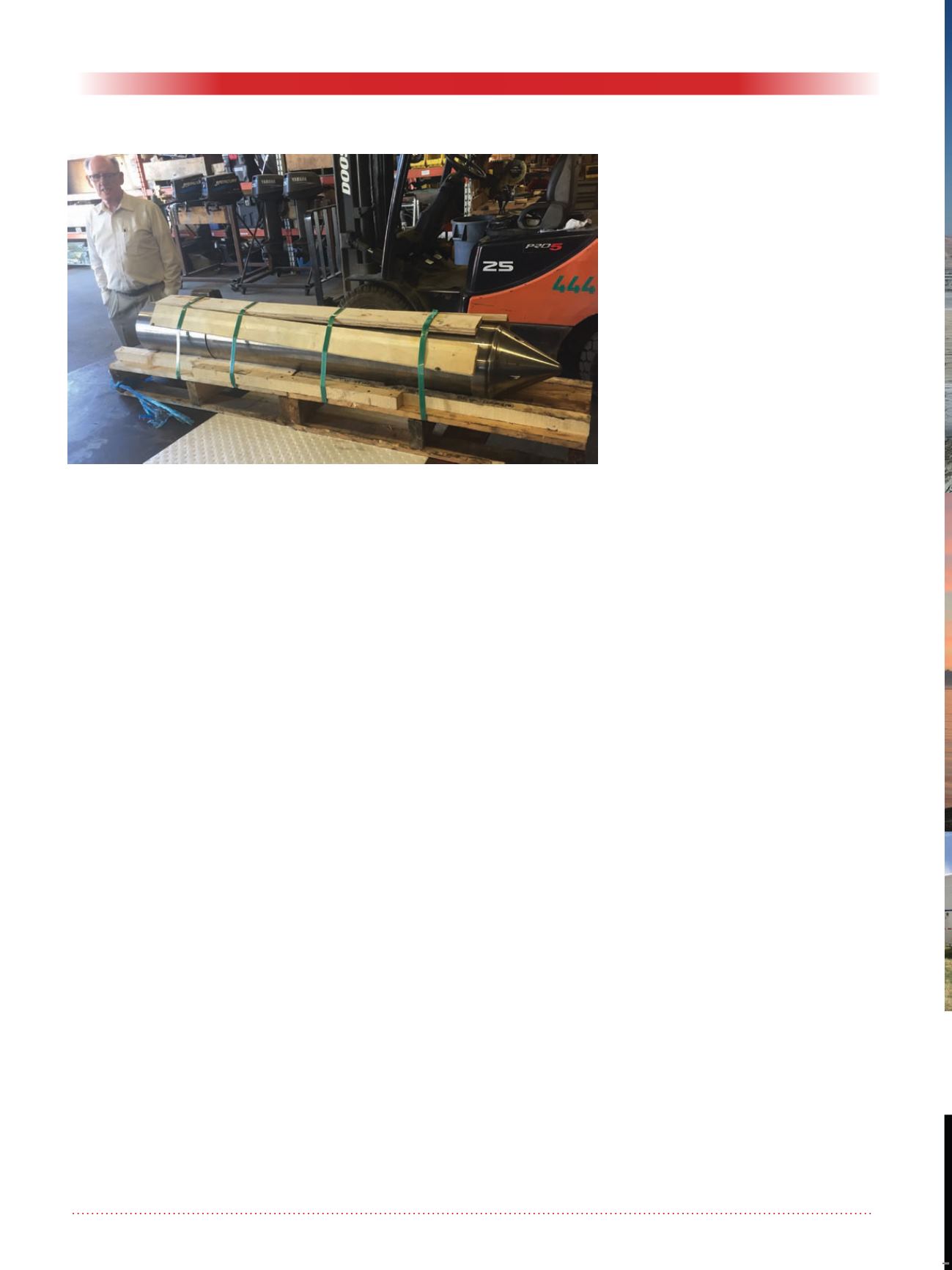

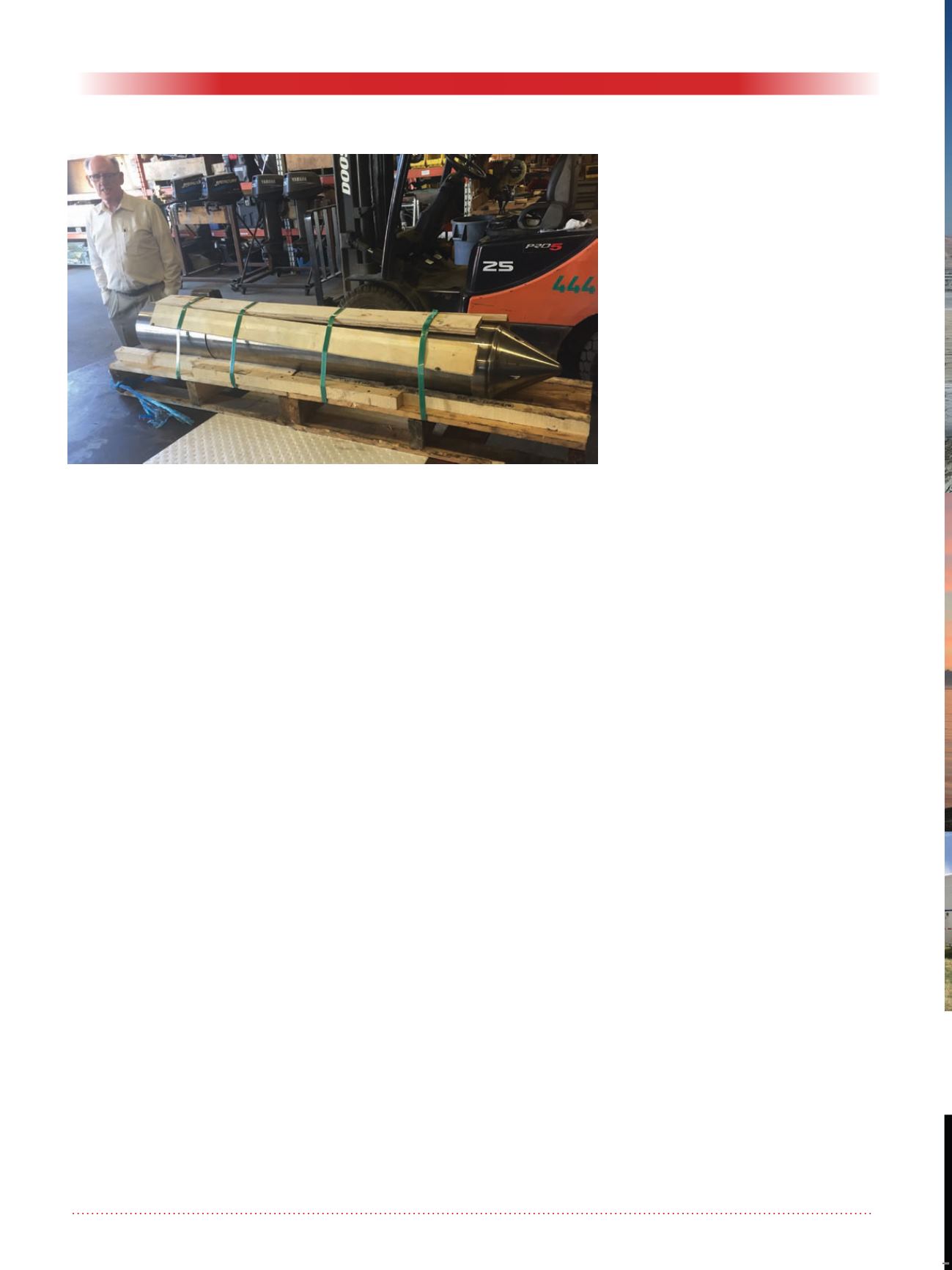

Fig 7 shows the current

PM

as it is

comes from the machine shop. It

differs from the machine used at

Molikpaq and at the two mine sites

discussed above. In the earlier mod-

els the filter/drain stood above the

air-motor and eccentric, making the

overall machine length 2.9m (9.4ft).

In this case the seepage intake sec-

tion is wrapped around the vibrator

thereby reducing the overall length

to 5ft (1.5m); the OD in both cases is

the same 190mm (7½”). The power

source will now be top-drive using the

contractor’s choice of engine.

Apart from that there have been two

recently patented additions to the

PEL

toolkit :

1. In weaker ground environments,

such as deltaic deposits and mine

tailings of various gradations,

the filter of the well screen could

become impervious if the open

spaces between its helically wound

wire became plugged by cohesive

layers existing within the material

being treated. A newly devised

module (US patent 10240314),

capable of rectifying this situation

will henceforth become a stan-

dard part of the

PM

. Of practical

importance is that this capability to

remove such smearing can be acti-

vated remotely while the machine

is still at depth.

2. What we call our Trident deploy-

ment array (US patent 8419316)

consists of three separate

PM

strings structurally harnessed

together so that their long axes are

vertical and are spaced apart later-

ally in an equilateral configuration.

The mere fact that there are three

excitable tools in the ground at the

same time, and in close proxim-

ity, opens a whole new prospect

in ground improvement technol-

ogy. This is because each of the

three neighbouring machines can

be made to perform their functions

independently, leading to many

combinations of their vibratory

and hydrodynamic forces. Two

applications of this configuration

come to mind:

a. The soil within the compass of the

three separate prongs could be

made into a very dense column

which would provide seismic-re-

sistant deep foundations capable of

carrying heavy structural loads.

b. Water could be pumped into, or

sucked out of, the ground by

each poker either in tune with its

partners, or in a cooperative man-

ner such as to create a flow in any

lateral direction between them.

This procedure could be enacted in

order to clean up polluted ground-

water in the soil between the

pokers.

Summing up

My hope is that what is presented

above, from field observations and

data recorded at three distinctly differ-

ent sites, is sufficient to convince the

reader that the Phoenix Machine hard-

ware and our procedures, are worthy

of consideration when geotechnical

engineers and ground improvement

contractors are faced with the prob-

lems arising out of loose or weak

foundation conditions. And, to quote

Ralph B. Peck: “Whatever the expla-

nation, I think your idea of simultane-

ous vibration and drainage has a lot of

promise in practice” (Ref 4).

Please note: More detail and data than

can be printed here can be found at

References

Donald W. Taylor (1948) Funda-

mentals of Soil Mechanics, John

Wiley, London.

W.E. Hodge (1988) “Construction

Method for Improving Underwater

Sand Fills” ASCE

Geotechni-

cal Division,

Specialty Conference

on Hydraulic Fill Structures,

Fort

Collins.

G. Baldi et al, (1982) “Design Parame-

ters for Sands from CPT”,

Pro-

ceedings of the Second

European Symposium on Penetra-

tion Testing,

ESOPT II, Amster-

dam, Vol 2.

R.B. Peck, (November 1998) Personal

correspondence.

William E. Hodge

Figure 7: The current PM as delivered by machine shop.