Geotechnical News December 2011

27

GEOTECHNICAL INSTRUMENTATION NEWS

ous materials typically used for back-

fill when installing a VWP in a boring.

Water pressure was applied from the

bottom of the chamber directly on to

the surrounding material, a distance

of 4 to 7 inches from the diaphragm of

the VWP. Therefore, the water pressure

had to propagate through 4 to 7 inches

of the surrounding material before it

reached the piezometer diaphragm. In

order to model field conditions, I at-

tempted to saturate all surrounding

materials by introducing de-aired wa-

ter into the bottom of the test chamber

and allowing air to escape out of the

top, until water was flowing out of the

top of the chamber. Then I capped the

top of the chamber and began apply-

ing pressure and recording data. This

method resulted in incomplete satura-

tion of the grout and clay. I suspect that

the incomplete saturation may have re-

sulted in slower response times.

To setup the tests, the VWP was

suspended in the triaxial test cham-

ber, and the surrounding material was

placed around it. For sand, water and

clay, I had the triaxial chamber con-

nected with the top and bottom plate,

and poured the surrounding material

through the hole in the top. For grout, I

created a false bottom with mastic tape

and a plate approximately 1 inch above

the bottom of the cylinder. The VWP

was suspended in the cylinder over this

false bottom, and grout was poured in

and allowed to cure. Two Geokon mod-

el 4500 VWP sensors were used, with

pressure maximums of 250kPa, both

of which were periodically tested for

accuracy by submerging them in the

triaxial test chamber filled with water,

applying pressure into the chamber,

and observing the pressure recorded by

the VWPs. I tested to see if varying the

installation methods and surrounding

material affected the response times,

or ultimate accuracy of the instrument.

Each installation method was tested

twice, once with each VWP.

Methods of installation for the VWP

tests are presented in Table 1:

The sand I used in the testing was

Colorado silica sand. The grout mix

was 1 gallon water to 3 lb cement to

approximately 1 lb bentonite grout. To

mix the grout, water and cement were

added and mixed first in a 5 gallon

bucket, and then bentonite was added

and mixed in. I used the Mikkelsen and

Contreras et al method of grout mixing,

adding bentonite until a consistency

was reached in which the grout formed

craters when dripped. New batches

were mixed for each separate test, and

the grout was allowed to cure for 48

hours. The bentonite chips were 3/8

inch chips, hydrated for approximately

a week.

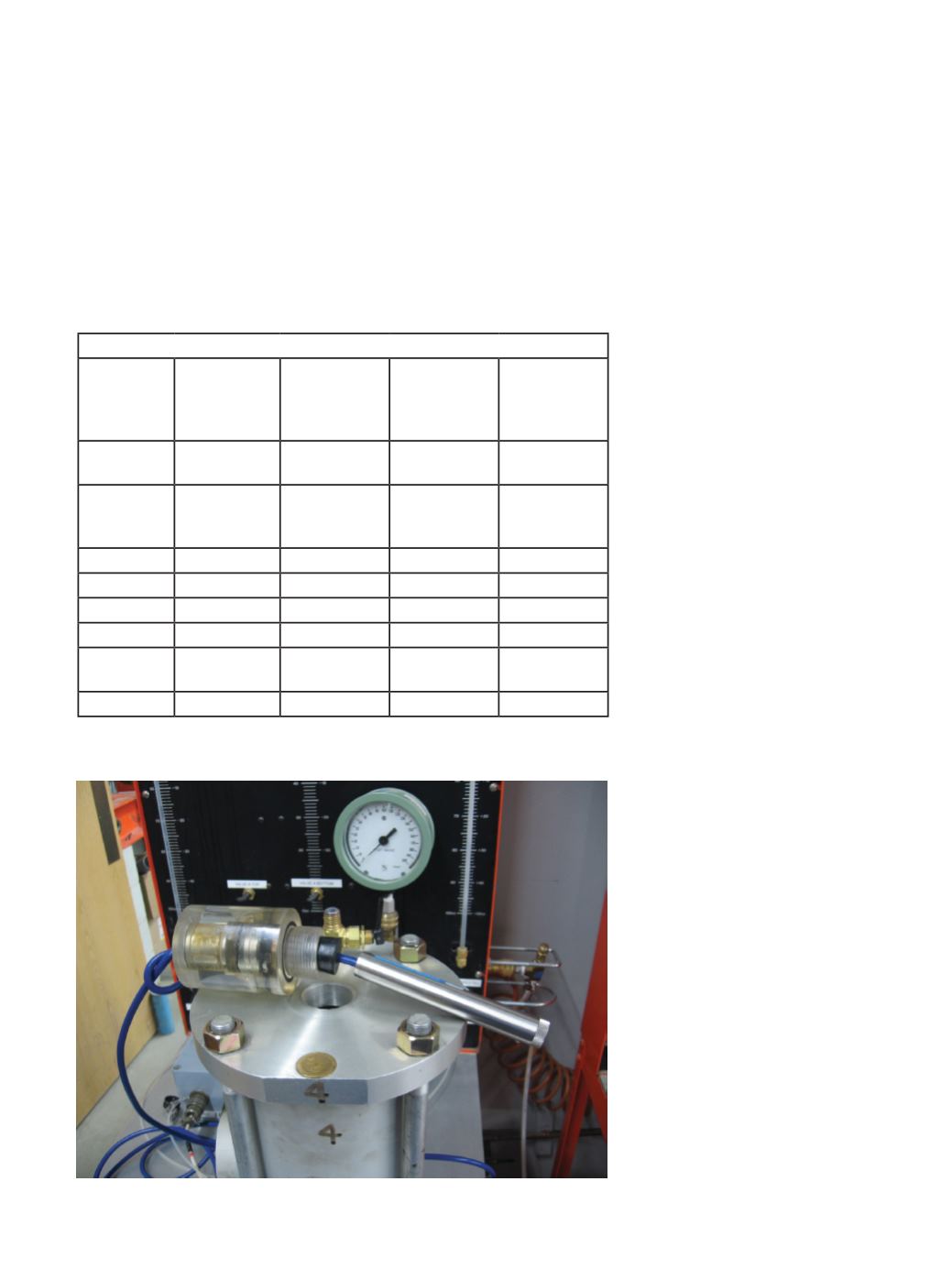

Figure 1 shows the typical setup

before the VWP is installed. The back-

ground is the triaxial compression test

frame that was used to apply pressure

to the chamber. I connected the VWP to

a datalogger, which recorded the VWP

data every 5 seconds. I compared data

from the VWP to the pressure applied

by the triaxial compression test frame.

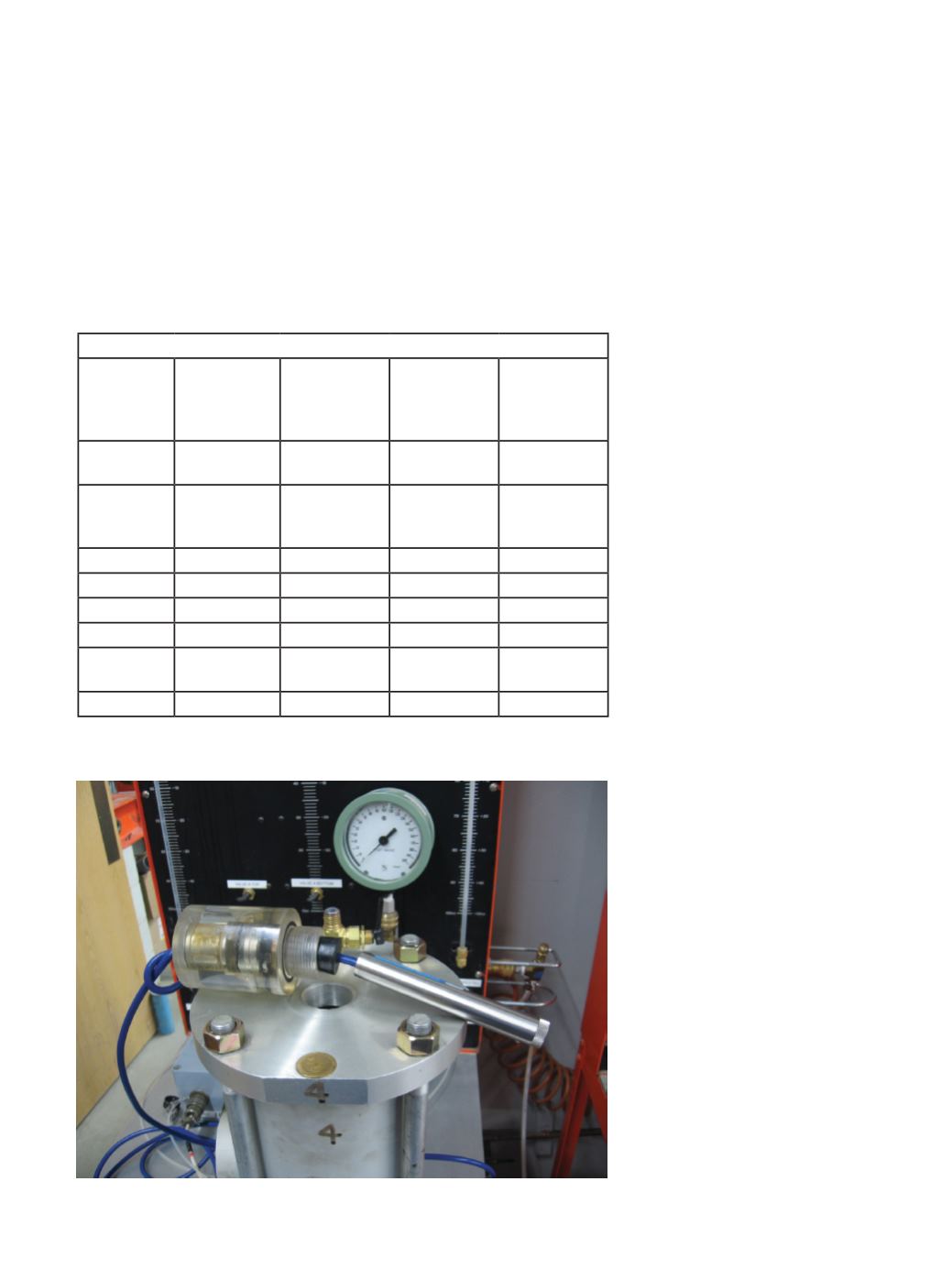

Table 1. Tests of VWP Installation Methods

Test Number Surrounding

Material

Diaphragm

Tip Direction

Pre-Saturated

(test a) or Not

(test b)

Using a

Protective

Canvas Bag or

Not

1 (a and b)

Water

Up

Both tests

performed

No

2

Water

Down

No,

Intentionally

capturing air

No

3

Sand

Up

No

No

4

Sand

Up

No

Yes

5

Grout

Up

Yes

Yes

6

Grout

Up

Yes

No

7 (a and b)

Grout

Down

Both tests

performed

No

8

Clay

Up

No

No

Figure 1. Test setup.