28

Geotechnical News December 2011

GEOTECHNICAL INSTRUMENTATION NEWS

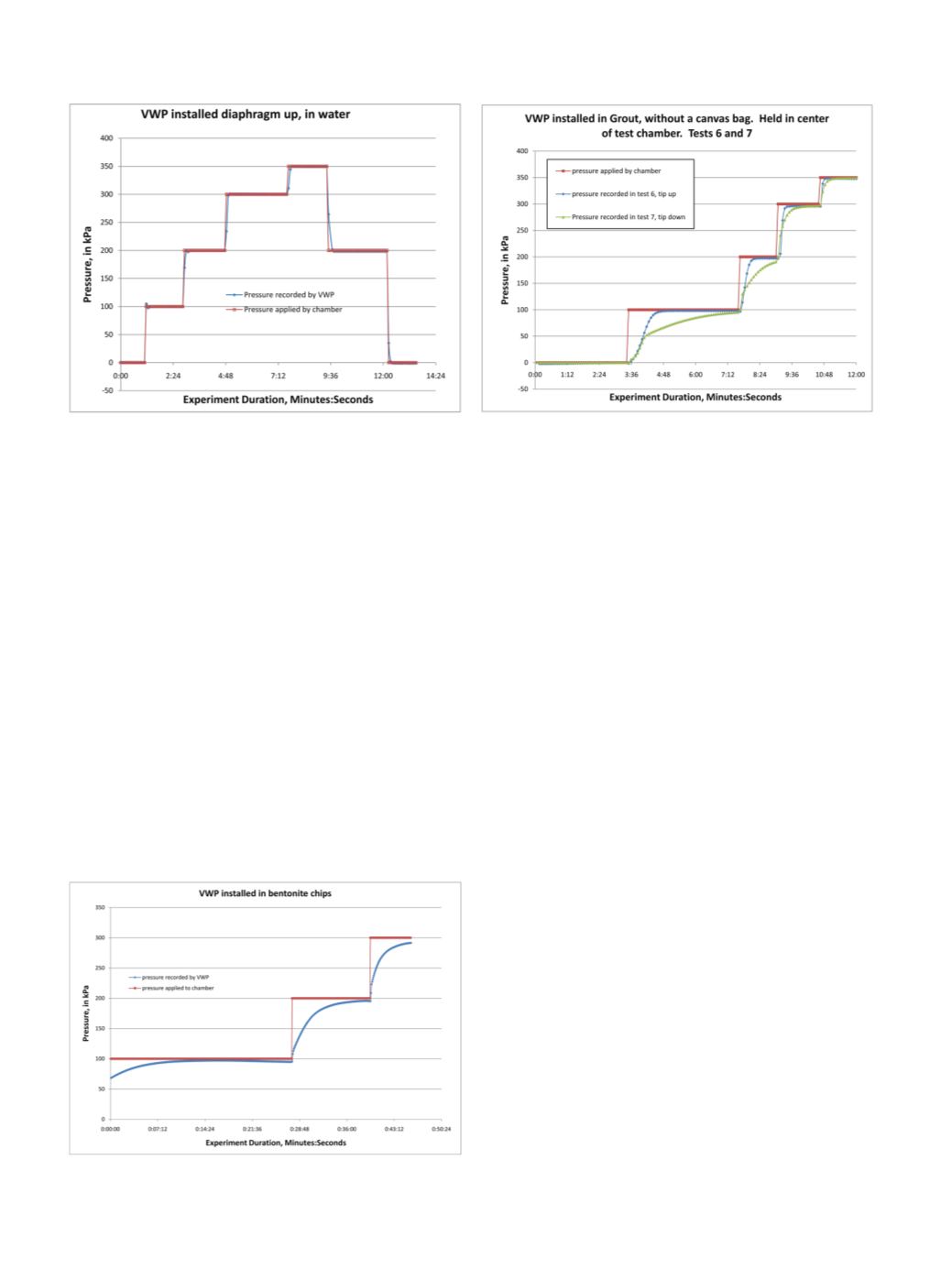

Applied pressure to the test chamber

was recorded manually and was incre-

mentally adjusted to test the response

time of the VWP to the differing pres-

sures applied at the base of the cham-

ber.

Test Results

With all of the installation methods

in sand or water, the VWP responded

within less than 20 seconds to changes

in pressure, and reliably recorded

pressure, with maximum errors of 3kPa

and a standard deviation less than 0.1

kPa. Figure 2 shows the comparison

between the applied pressure measured

by the triaxial compression test

chamber and that recorded by the VWP

for test 1 a.

This response time and accuracy

was typical for tests 1 (a and b) through

5. It is also important to note, that

for one test, I intentionally captured

as much air as I could with the in the

chamber of the VWP between the filter

stone and the diaphragm, and it func-

tioned with similar response times to

those in Figure 2. It is also important to

note that the VWP installed in a canvas

bag in grout had response times closer

to a VWP installed in sand than a VWP

installed in grout without a bag. How-

ever, the long axis of the bag was al-

most as tall as the cylinder, which min-

imized the distance the water pressure

had to travel, a situation we wouldn’t

see in the field.

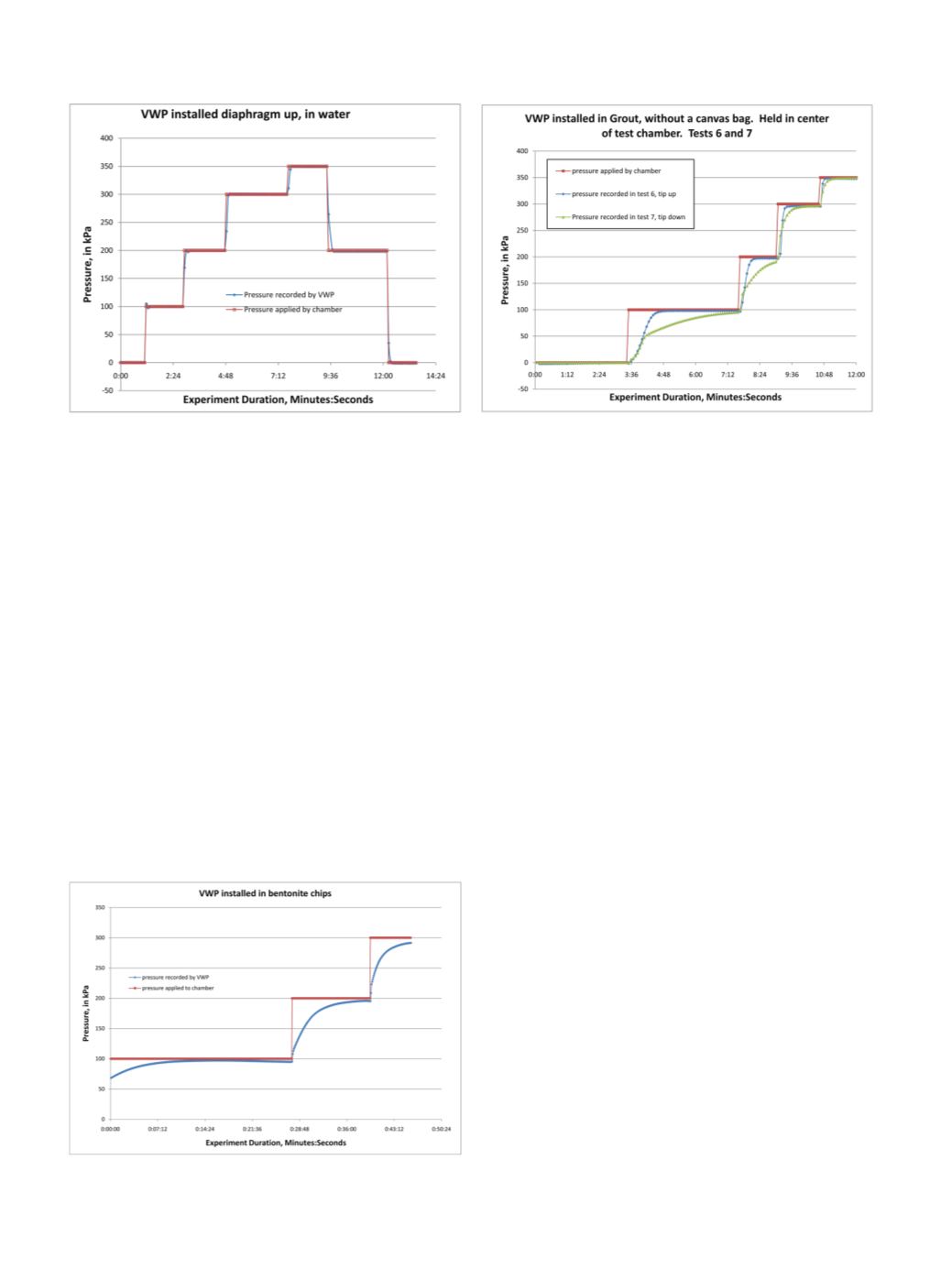

Figure 3 is the graph of response

times for test 6 and 7.

As shown in

Figure 3, there

is a larger de-

lay between the

pressure applied

by the frame

and the pressure

measured

by

the VWP for the

instruments in-

stalled in grout. I

suspect that this

is due to the in-

complete satura-

tion of the grout.

If air was present

in the grout, it

would compress

and dissolve into solution when pres-

sure was added, which would delay the

VWP from responding to the effects of

the pressure added to the chamber. This

hypothesis is supported by the fact that

the incremental pressure steps from

100 to 200 kPa has a shorter response

time compared with the intervals from

0 to 100 kPa, potentially because the

air is already partially compressed and

dissolved. In addition, it was observed

that more water had to be added to in-

crease the pressure from 0 to 100 kPa

in the grout than from 100 to 200 kPa.

In general, as the testing sequence pro-

gressed from water to sand to grout

to clay, I observed that progressively

more water was required to increase

the pressure in the chamber. Assuming

that the VWP would be installed below

the water table in the field, I would ex-

pect to eventually have complete satu-

ration in the backfill material. As such,

this lengthened response time may be

a factor of the laboratory testing, and

not a factor in field installations. This is

supported by the fact that the VWP in-

stalled tip down (which may have cap-

tured additional air) had a larger (but

still only 120 second) response time to

the increase in pressure.

I tested the difference between in-

stalling the VWP diaphragm up and

diaphragm down in grout in tests 6

and 7. These tests had very similar re-

sults. The VWP installed diaphragm

down took twice as long to respond

to increases in pressure. However, the

Figure 2. VWP installation diaphragm up, in water, without a

canvas bag.

Figure 3. VWP installed diaphragm up and down, in grout,

without a canvas bag.

Figure 4. VWP installed diaphragm up, in bentonite clay,

without a canvas bag.