34

Geotechnical News •March 2015

GEOTECHNICAL INSTRUMENTATION NEWS

All information provided here consti-

tutes a robust geological model of the

area and the ongoing subsidence. To

control the evolution of subsidence

where vulnerable buildings or lifelines

are in the vicinity of susceptible soils,

monitoring the subsoil pore water

pressure is sufficient (green bars in

Figure 1).

Francesca Bozzano

CERI Research Center and

Department of Earth Sciences -

Sapienza University of Rome,

Piazzale Aldo Moro 5, 00185,

Rome, Italy.

Tel. +39-6-49914924

email:

The use of fully-grouted piezometers in a streambed

Raymond D’Hollander, Paul Roth, Shane Blauvelt, James O’Loughlin

The site is a stream located in the

northeastern United States with

contaminated sediments in the chan-

nel bed. Data regarding both verti-

cal hydraulic gradients and absolute

piezometric pressures were required

during remedial design to evaluate

stability of the bed and banks for an

excavation scenario and for use in

modeling a potential chemical isola-

tion cap.

Selection of fully-grouted

method of piezometer

installation

Available data during the pre-design

planning indicated that the stream

water surface and adjacent ground-

water elevations are variable with a

typical annual range of about 1 m. The

groundwater data indicated the poten-

tial for significant upward gradients

and for some of the groundwater to

be saline. The water depth above the

proposed piezometer locations was

typically about 1 to 3 m. Shearing by

ice, debris, and high flows as well as

the potential for artesian groundwater

made an open standpipe piezometer

impracticable for measurements per-

formed over an extended period.

Vibrating wire piezometers with on-

shore data acquisition systems were

selected for measuring the groundwa-

ter pressures in the streambed. It was

desirable to position the top piezom-

eter in the creek at about the expected

post-remediation sediment surface

to evaluate the piezometric pressure

and gradient likely at that point. This

position ranged from 0.6 m to 1.8 m

below the sediment surface. The shal-

low depth of these piezometer raised

concerns with the effectiveness of

conventional bentonite seals, particu-

larly given the potential for erosion

in the stream bed. Also, access to the

locations was difficult and the ability

to install the two piezometers quickly

in the same borehole was desirable.

Based on these considerations, the

fully-grouted method was selected for

installing the piezometers in the creek,

as described in McKenna (1995) and

Contreras et al. (2008).

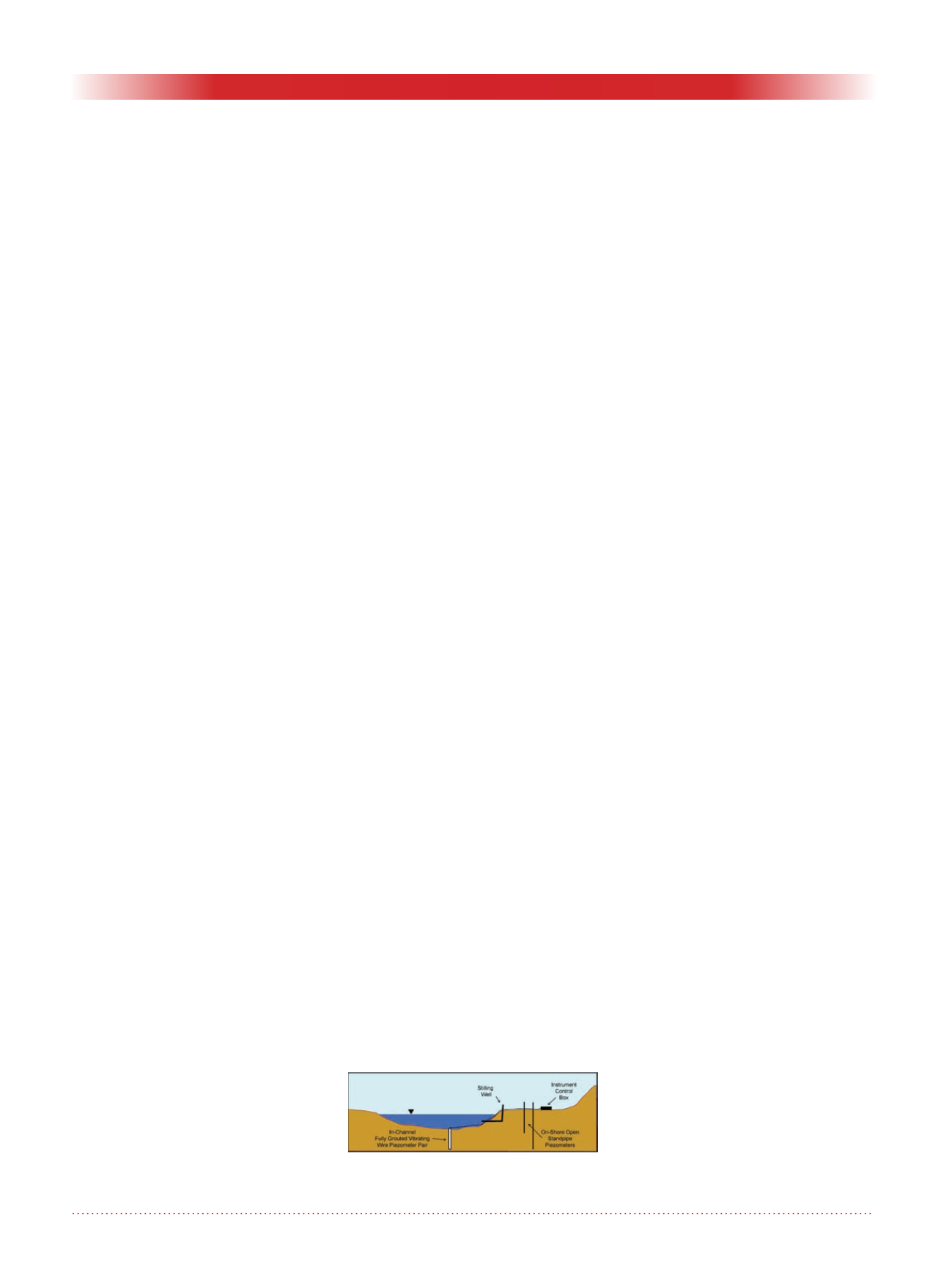

Stream cross-section

instrumentation

Instrumentation cross-sections were

installed at six locations along the

stream. Each instrumentation cross-

section included two vibrating wire

piezometers in the channel, a stilling

well, and two open standpipe piezom-

eters installed at the top of the bank,

as shown on Figure 1. The fully-

grouted piezometers in the channel

were installed in vertical pairs with the

bottom piezometer approximately 2.1

m to 3.3 m below the top piezometer.

The on-shore standpipe piezometers

were installed so that the top piezom-

eter was located near the groundwater

surface and the deeper piezometer

at about the elevation of the bottom

piezometer in the channel pair. Due

to the potential for saline groundwa-

ter, bentonite seals for the standpipe

piezometers were installed using ben-

tonite pre-hydrated with fresh water

and then tremied into the borehole.

Fully-grouted piezometer

installation

Drilling

The fully-grouted piezometers were

installed in the center of the channel

using a CME 45C drill rig on a seg-

mented barge, as shown in Figure 2.

The barge was disassembled and reas-

sembled between some of the cross-

sections due to the presence of low

bridges. The borings were advanced

using mud rotary and casing.

Piezometer and tremie pipe assembly

Unvented vibrating wire piezometers

with a range of 0.2 MPa were used.

They were taped to the Schedule 40,

19-mm diameter PVC threaded pipe

used to tremie the grout, as shown

in Figure 3. Depending on the water

depth, the top pipe length was 1.5 m or

3 m to allow for a convenient stick up

out of the water for grouting; this top

length was unscrewed after grouting

so that the finished top of the pipe was

below the sediment surface. The total

pipe length was measured to fit the

finished depth of the borehole, so that

the pipe would rest on the borehole

Figure 1. Typical instrumentation

cross-section.