Geotechnical News • September 2015

33

GEOSYNTHETICS

Jonathan Fannin, Editor

Professor of Civil Engineering, University of British Columbia

Writing in this column for the GN

June 2015 issue, I reported on the

material properties of a geotextile, not-

ing that inherent differences between

the manufacturing processes of a

woven and a nonwoven geotextile

impart differences to the opening

size distribution of the fabric and, by

association, differences to the capacity

for flow of water across the plane of

the fabric. Likewise, there is a differ-

ence in tensile strength and stiffness

that results from the manufacturing

process.

The use of a geotextile in filtration

applications is predicated on it having

adequate strength to ensure no adverse

damage throughout the process of

installation (termed ‘construction sur-

vivability’) and that it can also endure,

thereafter, the working environment of

the application (termed ‘durability’).

Upon selecting a suitably strong and

durable geotextile, the requirement

for soil-geotextile filtration compat-

ibility is contingent on there being no

unacceptable erosion as a consequence

of soil loss through the geotextile

while, at the same time, providing for

unimpeded flow of water from the soil

through the geotextile.

It is widely-accepted practice to select

a candidate geotextile for routine

construction works with reference to

(i) criteria for strength and durabil-

ity, given the anticipated method of

construction service environment,

(ii) an empirical rule governing base

soil retention, and (iii) an empiri-

cal rule governing base soil perme-

ability. Typically, the approach has

been found conservative, and yields a

geotextile filter for which the margin

of safety is believed acceptable. How-

ever, the exact nature of that margin of

safety is not quantified – therefore, in

applications that are deemed critical

or severe, the state-of-practice is first

to identify a candidate geotextile on

the basis of the reported values for

Jonathan Fannin

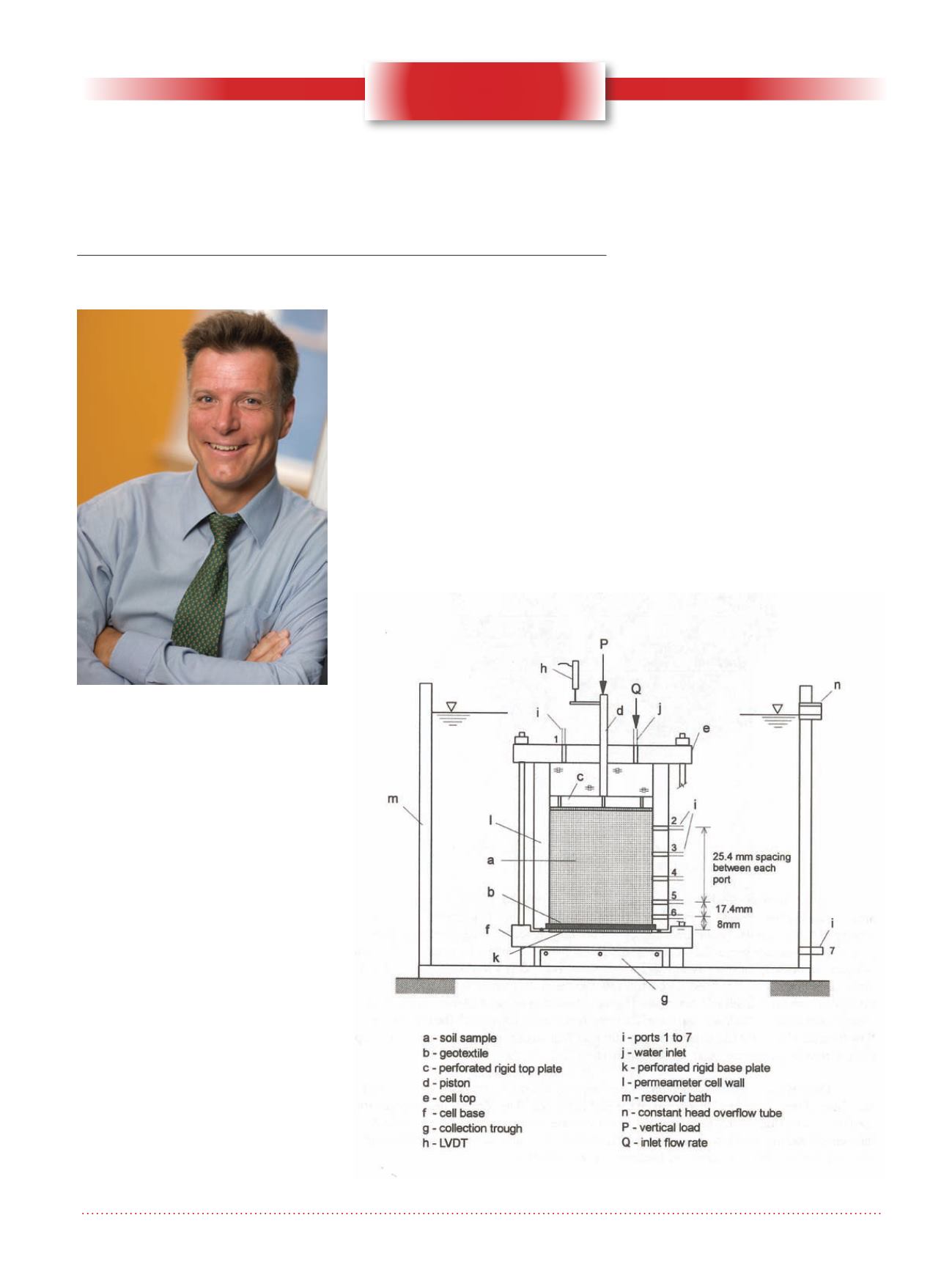

Figure 1. Configuration of the gradient ratio test.