Geotechnical News • September 2015

35

GEOSYNTHETICS

loose condition, flushing the specimen

with carbon dioxide in order to expel

oxygen and other gases in the per-

meameter, and then slowly filling the

specimen with water (50mm/hr). The

specimen should be kept in a no-flow

condition overnight to ensure com-

plete saturation.

In principle, the ASTM D 5101 gradi-

ent ratio test device (shown with an

additional top loading assembly in Fig.

1) provides an attractive method for

assessing soil-geotextile compatibility

because the candidate geotextile is

tested against the soil to be protected,

water is permeated through the sys-

tem, and any potential for clogging or

piping is evaluated directly. Interpreta-

tion of the gradient ratio test is based

on measurements of head loss that

occur in the soil and across a 25 mm

thick zone adjacent to the geotextile

(GR

25

). Fannin et al. (1994a) intro-

duced an additional port 8 mm above

the geotextile (see Fig. 1), in order to

gain a more sensitive measure of head

loss in the soil-geotextile ‘bridging

zone’ that was termed the modified

gradient ratio (GR

8

). The benefit of

adopting such an additional measure-

ment close to the geotextile is now

well-recognized (see for example,

Austin et al., 1997; Palmeira et al.,

2005).

Reproducibility of the test is very

dependent on achieving full satura-

tion of the reconstituted soil speci-

men. Fannin et al. (1994a and 1994b)

established an alternative means to

reconstitute homogeneous saturated

specimens, by means of water pluvia-

tion for uniformly graded soil and by

slurry deposition for broadly graded

soil. The specimen is leveled by

siphoning and, if appropriate, densi-

fied by light tapping with a soft ham-

mer. Preliminary testing identified the

need for adding a commercial liquid

algaecide to inhibit biological growth,

a finding that was further confirmed by

Fischer et al. (1999).

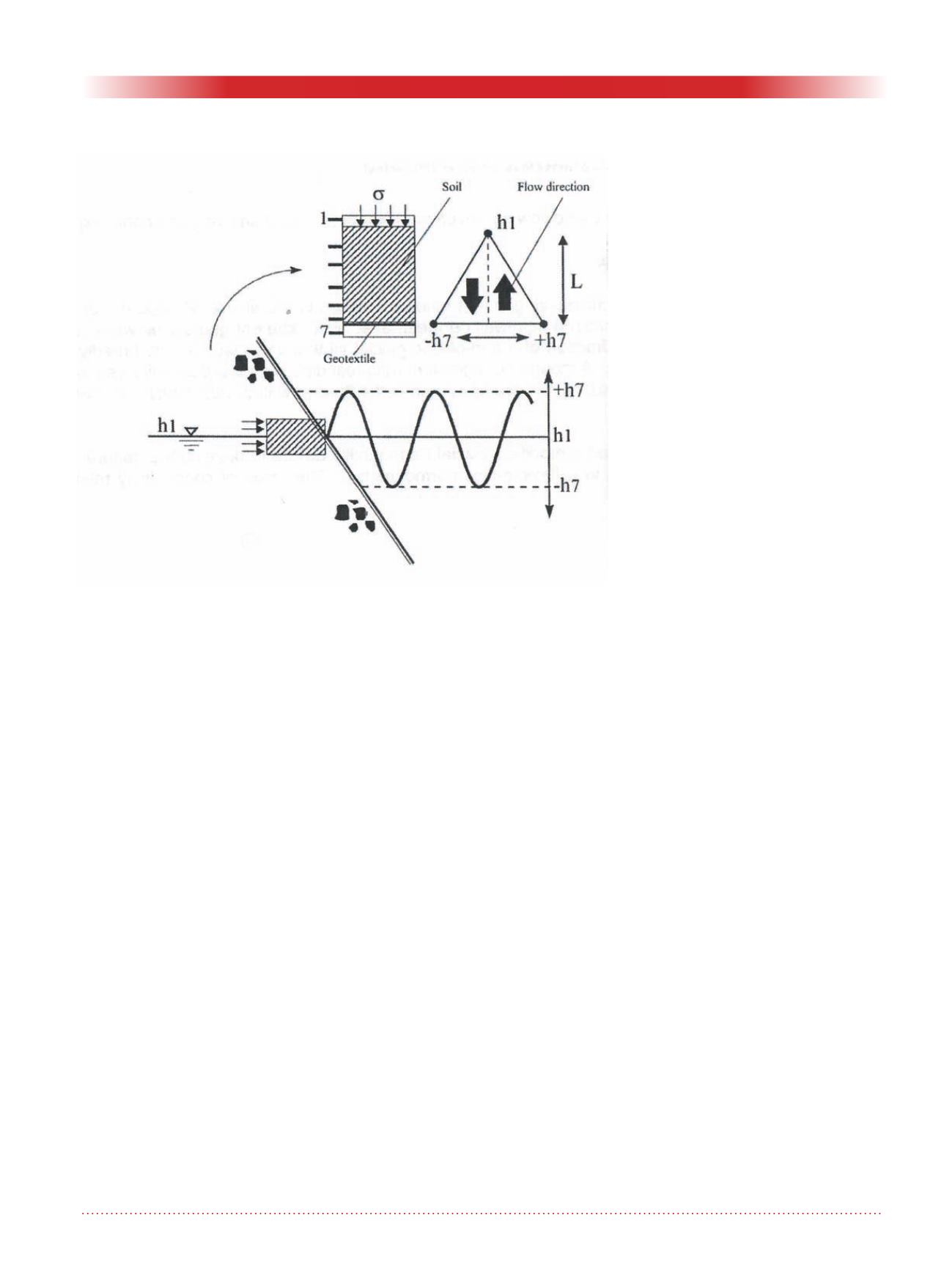

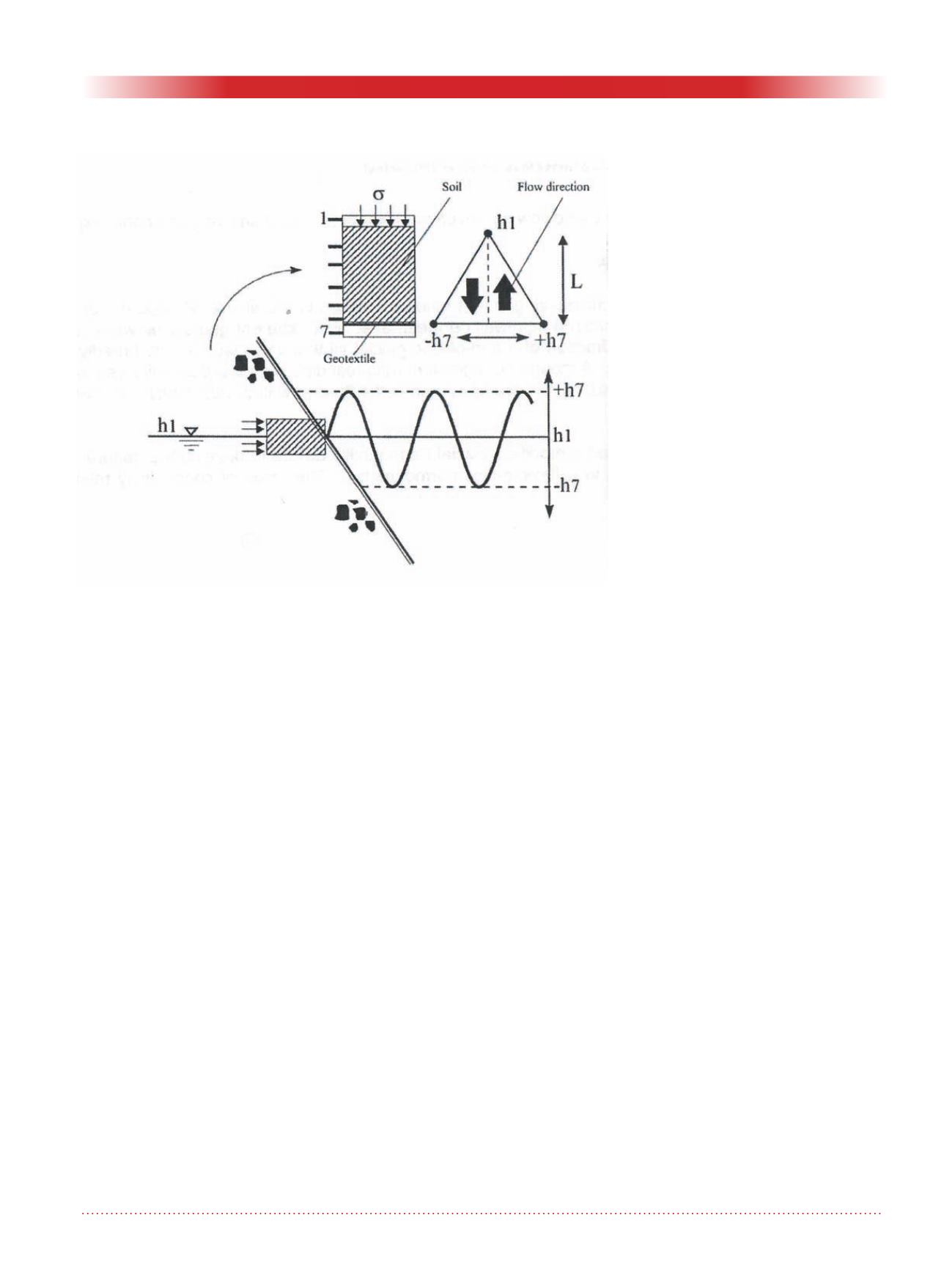

A conceptual illustration of the

approach to modeling cyclic flow in

a laboratory element test is illustrated

in Fig 3. Hameiri and Fannin (2002)

describe a modified gradient ratio test

device that was configured to impose

cyclic flow using head control, while

maintaining the ability to apply axial

load and collect soil passing through

the geotextile. Fannin and Srikongsri

(2007) report data using the same

device that show mass loss is sensi-

tive to confining stress and the period

of flow reversal, both of which are

believed to exert a significant influ-

ence on the ability of a bridging

network to develop in the base soil

adjacent to the geotextile. Extend-

ing the database of results to include

combinations of 9 different geotextiles

and 6 cohesionless soils (with 0.6 ≤

O

95

/D

85

≤ 2.8), Srikongsri and Fannin

(2009) examined factors controlling

soil retention by means of multi-stage

tests, based on the observed relation

between O

95

/D

85

and rate of mass loss

(g/m

2

per 100 cycles). No combination

of uniformly graded soil (C

U

< 2) and

nonwoven geotextile yielded a mass

loss for O

95

/D

85

≤ 2.25. Similarly, no

combination of uniformly graded soil

(C

U

< 2) and woven geotextile yielded

a mass loss for O

95

/D

85

≤ 2, however

a significant loss was encountered for

2.5 < O

95

/D

85

. In all cases the onset of

soil loss occurred at retention ratios

significantly greater than the empiri-

cal rule of O

95

/D

85

≤ 0.5 that has been

advocated for design (Holtz et al.,

1997). Likewise, by inspection, it can

be inferred that the onset of soil loss

occurred at retention ratios greater

than O

90

/D

90

≤ 0.5 to 1 that has also

been advocated for design (Schiereck,

2003). Accordingly, the empiri-

cal design rules for soil retention in

reversing flow appear very conserva-

tive.

Harney and Holtz (2001) report details

for a flexible-wall gradient ratio test

device that Bailey et al. (2005) then

used to compare with results obtained

using the standardized rigid-wall per-

meameter. Five different geotextiles

were examined in testing, in combi-

nation with the 2mm-minus fraction

of a non-plastic glacial till that was

classified as broadly-graded, gravelly,

silty sand, and each test was repeated.

Figure 3. Principle of the cyclic gradient ratio test.