34

Geotechnical News •September 2015

GEOSYNTHETICS

its strength, opening size and permit-

tivity from index testing, and then to

evaluate its suitability from laboratory

compatibility testing. In this article, I

review the origins and some notable

developments in North America that

have informed current practice in the

evaluation of soil-geotextile compat-

ibility.

The early work of the US Army Corps

of Engineers (Calhoun, 1972) on filtra-

tion compatibility included laboratory

permeameter testing to investigate

factors governing soil retention and

permeability. More specifically, the

laboratory filtration tests examined the

ability to retain silty base soils. Two

permeameters were used, a relatively

small one that accommodated a speci-

men 127 mm in diameter and large

one with a diameter of 292 mm. Each

was fitted with a series of manometer

ports on the rigid-wall of the perme-

ameter, at a vertical center-to-center

spacing of 25 mm above the geotex-

tile. The smaller permeameter was

used to evaluate clogging phenomena.

Following placement of the geotextile,

de-aired water was introduced and the

soil then placed underwater using a

tremie-type device, with care taken to

minimize segregation of the grains.

Unidirectional flow was applied in a

downward direction, with the hydrau-

lic gradient controlled by means of a

constant head reservoir. Interpretation

of the results included the reporting

of a ratio of two values of hydraulic

gradient, termed a ‘clogging ratio’

given by i

57

/i

37

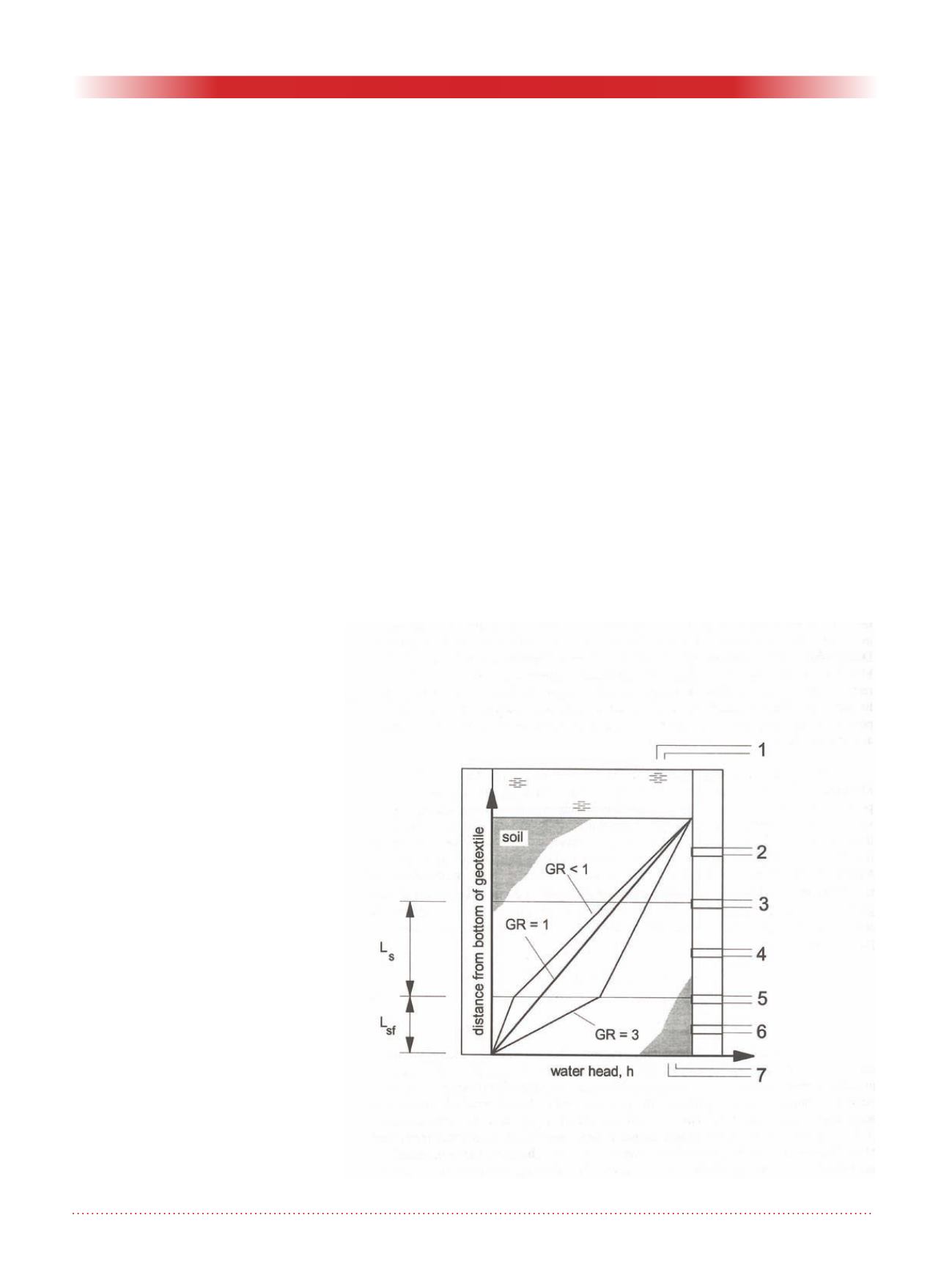

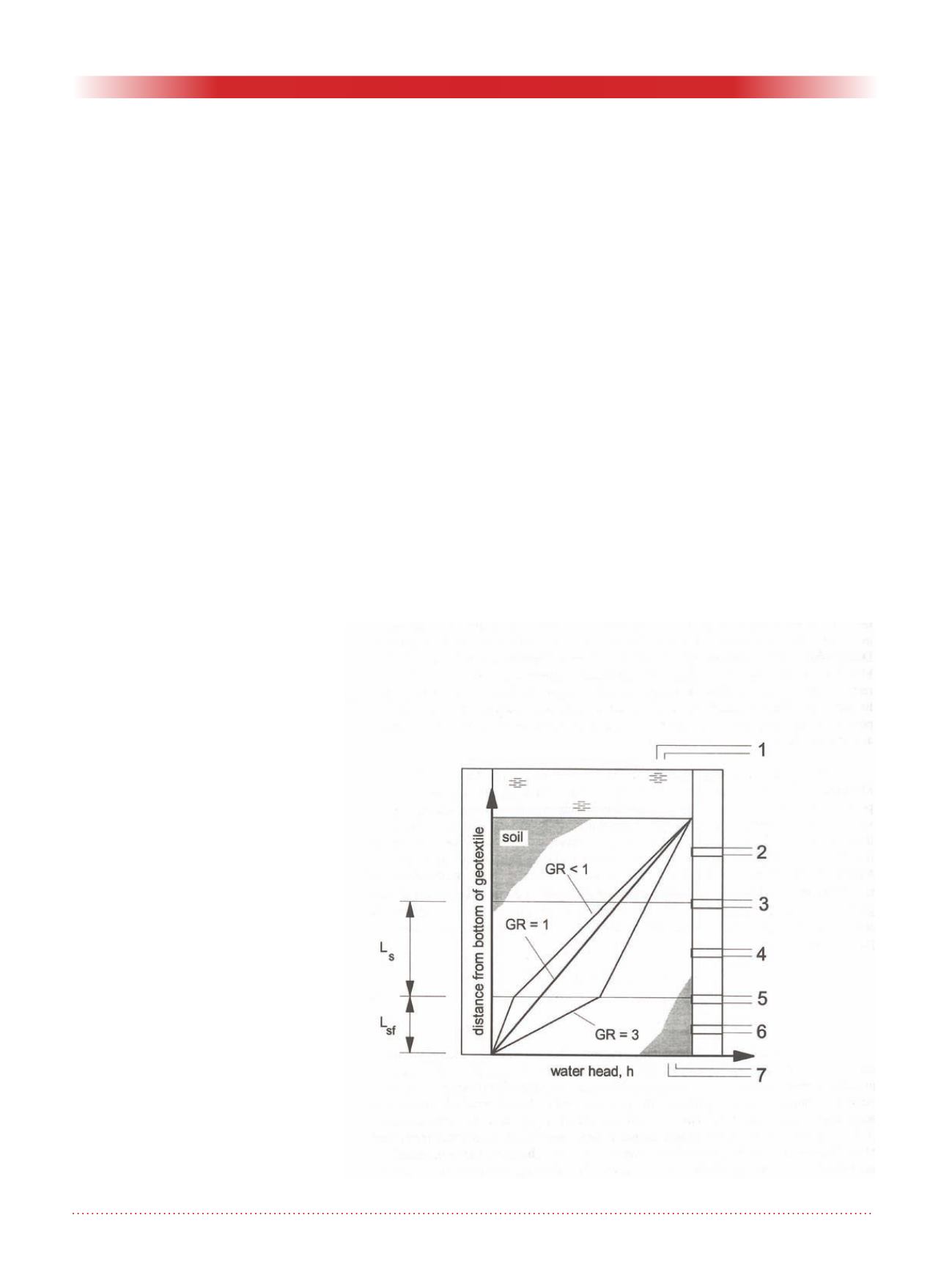

(with reference to Fig.

1) The value i

57

is measured across the

lower 25 mm of soil plus the geo-

textile, and the value i

37

is measured

across the lowermost 75 mm of soil

plus the geotextile. A ratio greater

than 1 was considered indicative of

clogging (Calhoun, 1972). Subsequent

work, using the same permeameter

and arrangement of manometer ports

(USACE, 1977), led to the clogging

ratio being replaced by a ‘gradient

ratio’ (GR) that was determined with

reference to i

57

measured across the

lower 25 mm of soil plus the geo-

textile, and i

35

measured across the

adjacent soil a distance 25 mm to 75

mm above the geotextile, yielding:

GR = i

sg

/i

s

where:

i

sg

= hydraulic gradient across the soil-

geotextile composite zone

i

s

= hydraulic gradient in the soil

In principle, ideal compatibility exists

for a gradient ratio = 1 (see Fig. 2). A

value greater than 3 was considered

indicative of ‘excessive clogging’, and

served to quantify the compatibility of

the soil and geotextile.

Haliburton and Wood (1982) used a

permeameter similar to that of Cal-

houn (1972) to evaluate the compara-

tive performance of two nonwoven

and four woven geotextiles. A sand,

and a gap-graded silt-sand (5 % to 80

% silt content), were used in testing.

The soil was reconstituted by a dry

tremied-placement technique, and

then slowly back-flooded from below

with tap water. This represents a minor

variation to the method of speci-

men reconstitution that was used by

Calhoun (1972) and it appears to have

exerted a strong influence on the sub-

sequent standardization of the test in

1992 (as ASTM D 5101). The experi-

mental findings were used to support

the quantifying of excessive clogging

by a gradient ratio value of 3 (from

UASCE, 1977), for which Lafleur et

al. (2002) subsequently proposed an

upper limit of 2 for blinding and lower

limit of 0.5 for piping.

The ASTM recommended specimen

reconstitution technique involves

placement of the soil specimen of

diameter 100 mm and length 100

mm above the geotextile in a dry and

Figure 2. Schematic illustration of the gradient ratio.