44

Geotechnical News • June 2018

GEO-INTEREST

CSattAR operates on ‘Sattar Image

Tracking’ (SIT) technique. SIT is

based on the same principles of ‘Digi-

tal Image Correlation’ techniques that

are widely used for laboratory experi-

ments and for short-term applications

such as bridge

vibration moni-

toring. SIT, on

the other hand,

is designed to be

robust for long-

term monitoring

practices where

light, tempera-

ture and weather

change.

The tracking

process involves

identifying the

new position of

pre-defined pix-

els within time-

lapsed images

and scaling

(reconstructing)

those movements

from image

coordinates into

global/metric

coordinates. In

long-term moni-

toring, the cam-

eras are likely to

experience tilt

and displacement

and this limits

the application of

using a camera

system to mainly

‘deformation’

monitoring rather

than ‘displace-

ment’ monitor-

ing. Also, movements are captured in a

two-dimensional space and there is an

imposed error that is caused by move-

ments along the third axis. CSattAR

is capable of quantifying these errors

and it often produces results that are

more accurate than using conventional

systems.

How does it compare to

Automated Total Stations?

The more projects I get involved with

the more I feel that our monitoring

work has been moulded by survey-

ing practices rather than follow-

ing engineering priorities. This has

made the industry adapt surveying

tools, focusing more on monitoring

‘displacements’ rather than ‘defor-

mations’ which are often the main

cause of damage. This evolvement

is understandable. In a construction

project, deformations such as strains

and angular distortions are not as

straightforward to interpret and they

are even harder to communicate or

manage. Automated Total Station

(ATS) systems bring that simplicity.

They will always be an important part

of a medium to large scale monitoring

project.

New technologies, such as CSattAR,

have the potential to reclaim measur-

ing some important deformations

without introducing complexities.

The following three deformations are

examples of this:

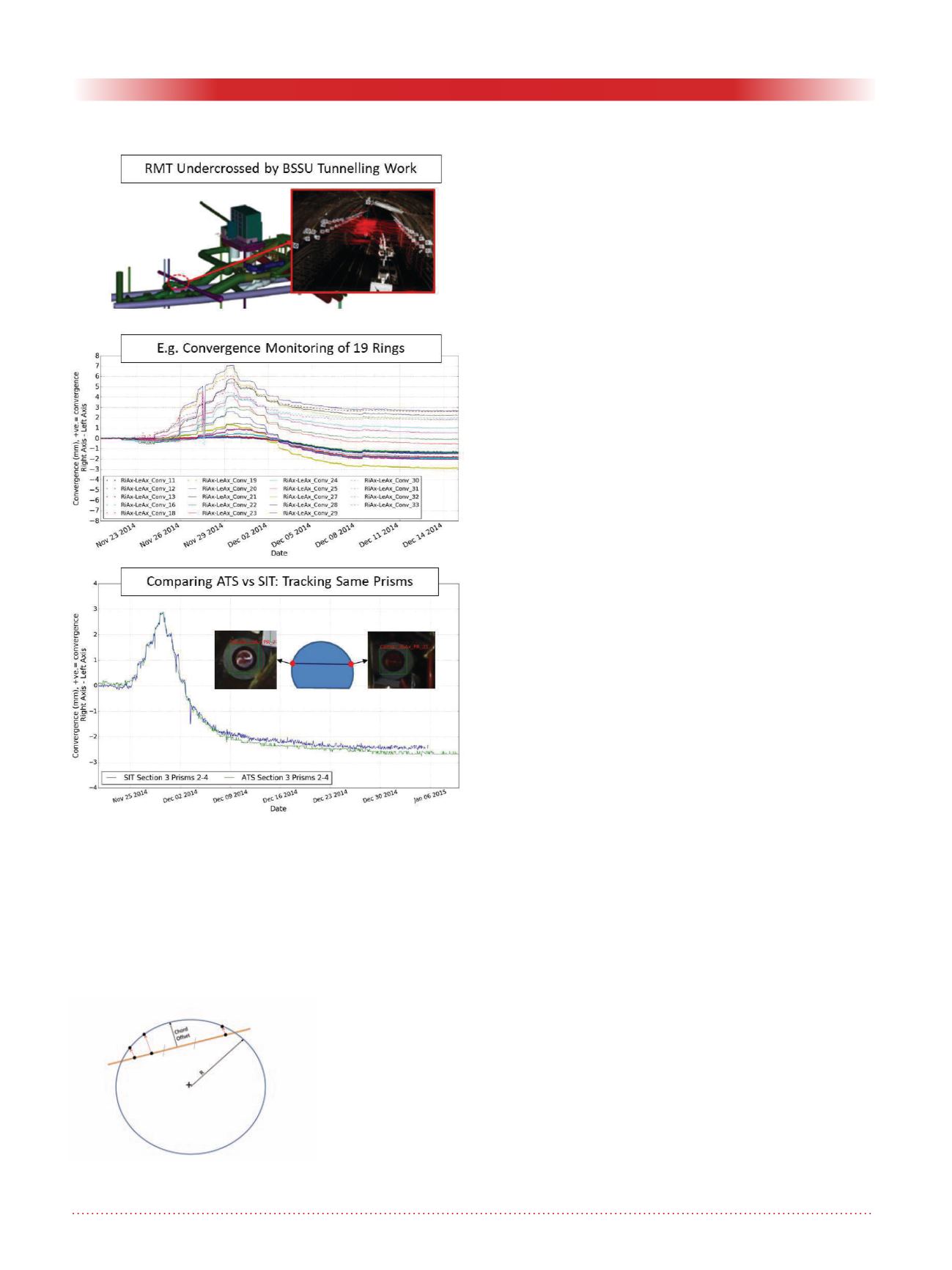

Convergence monitoring

The system has been installed in

several existing tunnels in order to

monitor and record the convergence

of tunnel sections/rings. This includes

monitoring the cast-iron rings of the

Central Line Tunnel and the Royal

Mail Tunnel (RMT) at Liverpool

Street Station area when influenced by

Crossrail work, RMT at Bond Street

Station area when influenced by the

Bond Street Station Upgrade work

(BSSU) and two of CERN’s concrete-

lining tunnels.

Convergence of tunnel sections/rings

is often carried out to ensure that tun-

nels do not undergo excessive ovali-

sations. Figure 01 shows the RMT

example at BSSU. In this case it was

possible to monitor the convergence

of almost every influenced ring (more

than 50 rings over 30m) by install-

ing three cameras. When tracking the

same prisms monitored by ATS, both

systems gave almost identical results

(Figure 01 – bottom).

CSattAR was able to measure a sig-

nificantly larger number of rings with

higher precision (as high as 0.01mm

when tracking CSattAR targets) and

at a fraction of the ATS costs. In

all of the cast-iron case studies that

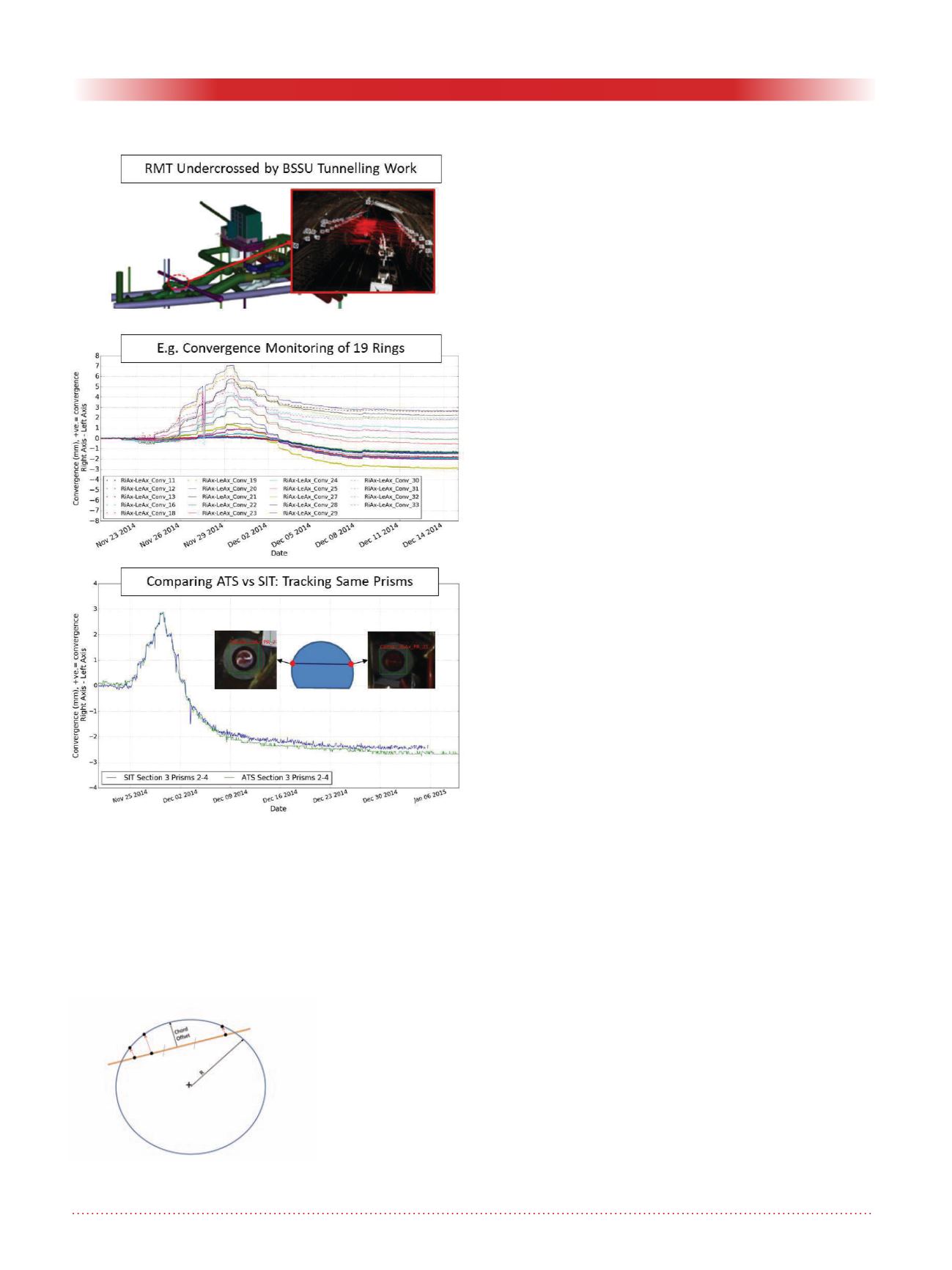

Figure 2. Measuring R from three

displaced points.

Figure 1. Monitoring convergence of Every Ring at Royal

Mail Tunnel – Bond Street Station upgrade.