28

Geotechnical News • June 2019

THE GROUT LINE

Contingencies were taken into

account in case the installation of the

H beam was not possible due to the

presence of boulders and the small

boreholes inside the boulders. Figure

#4.

In this specific case, where it was

not possible to install the designed H

beam, smaller diameter steel pipe-

piles were installed every single

column, instead of every third jet

grouted column.

Jet grouting execution

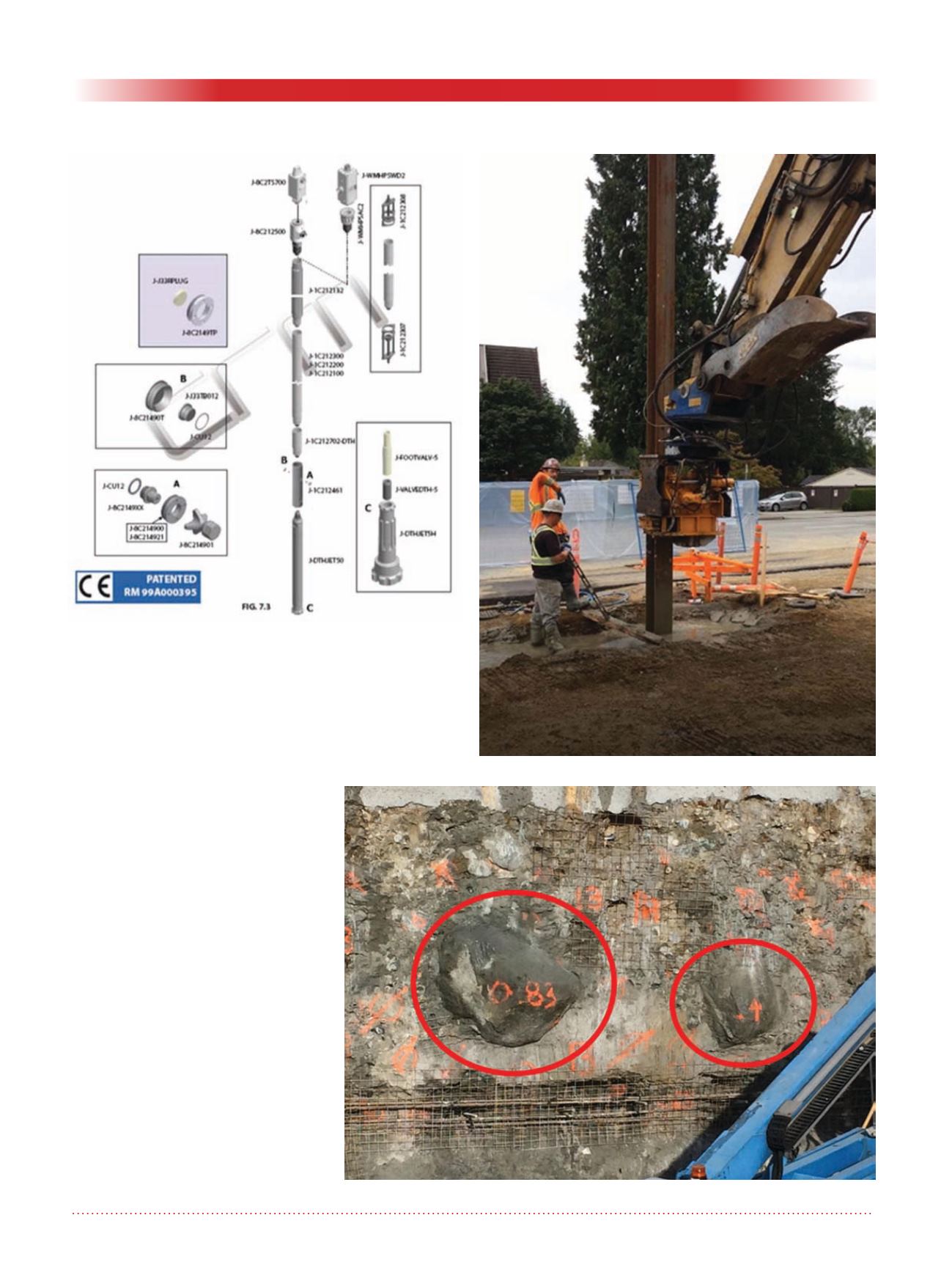

The main problem was definitely the

drilling in this heterogeneous, cobbly/

bouldery material. Usually with jet

grouting in soft soil the drilling is

done with simple tricone or drug-bit,

but in these difficult soil conditions

a special solution with dedicated

jet grouting tooling was adopted;

a conventional DTH with a special

monitor/tooling to allow drilling and

jetting without the need of pre-drill-

ing. Figure 5.

More than 500 columns were

installed from August to September,

2016, with a double

fluid system up to

15 meters deep. In

50 locations (out of

250) it was not pos-

sible to install the

Figure 5: DTH hammer for jet grouting.

Figure 6: H beam installation with vibrator.

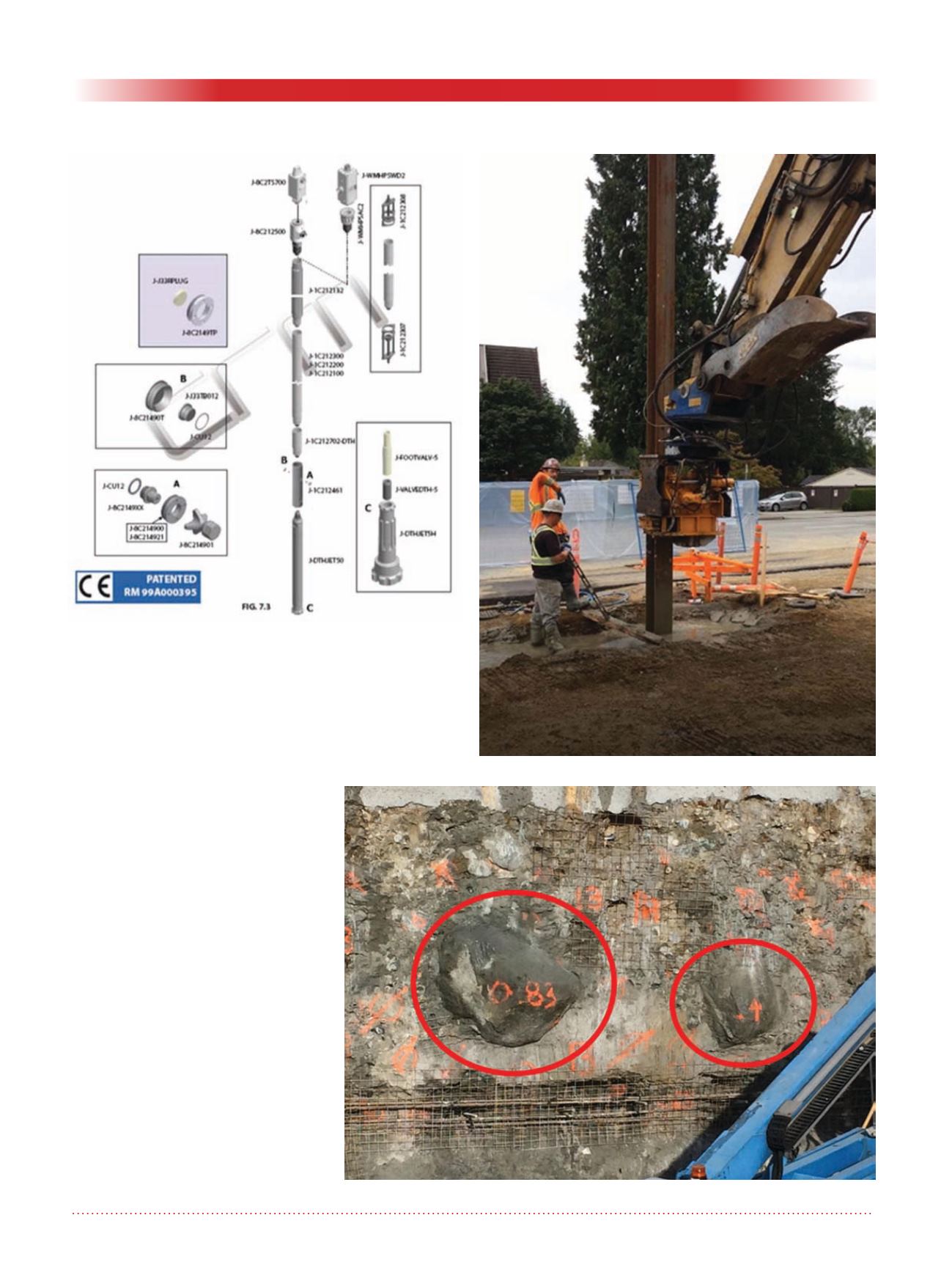

Figure 7: Excavated north wall with boulders Figure 7.jpg