Geotechnical News • June 2019

27

THE GROUT LINE

answers with a potential design and

operative approach.

The project

The project, the construction of a new

mixed residential/retail building, is

located in the District of North Van-

couver at the North end of Edgemont

Village. The area, resembling a dis-

torted square, is approximately 150m

wide. Figure #1. The new building

comprises up to 4 levels of above

ground structures and 3 to 4 levels of

underground parking.

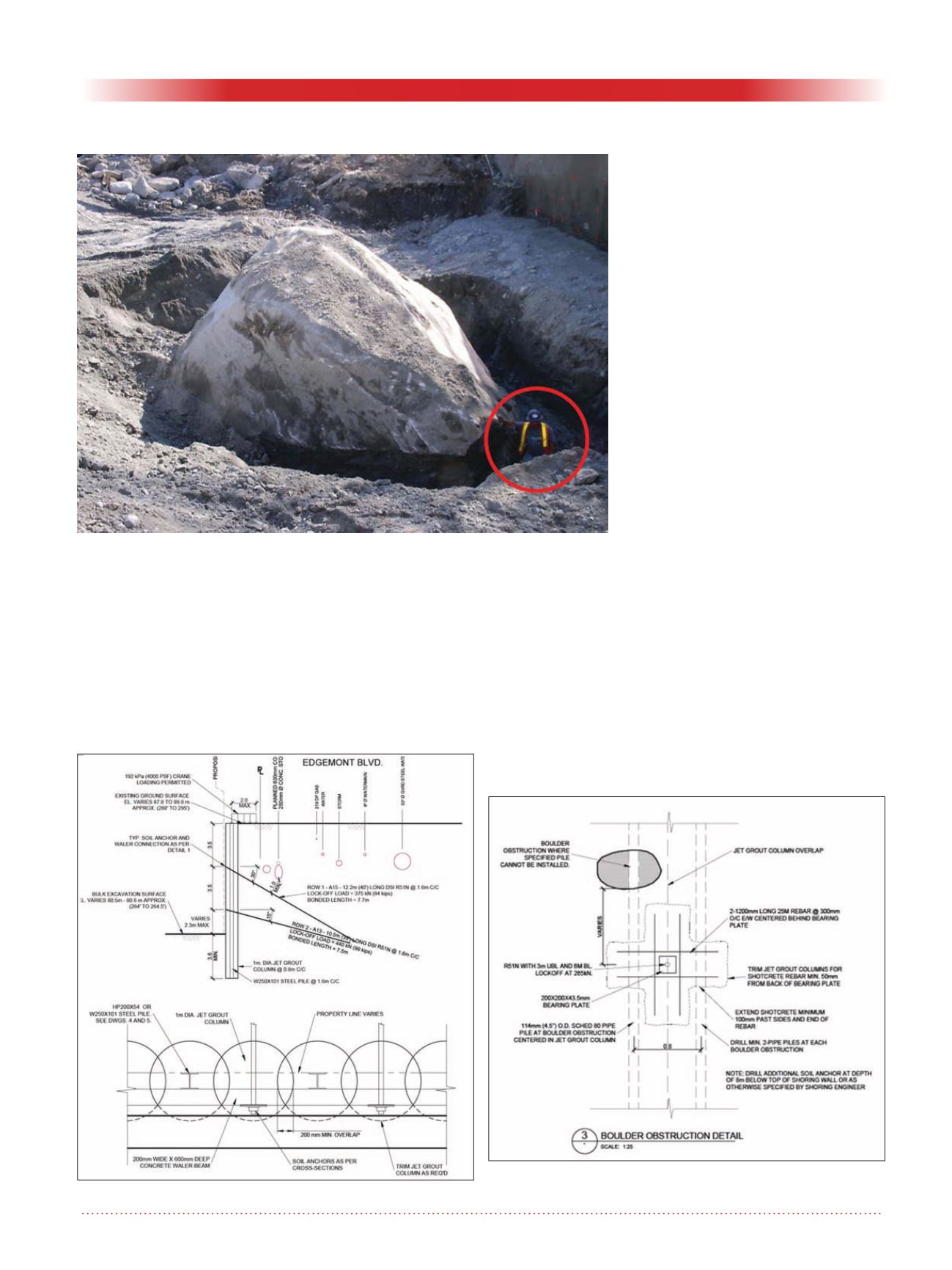

Soil conditions

The soil conditions present at site are

typical of the Vancouver North shore;

very heterogeneous soil and till with

presence of frequent cobbles and

boulders also of relevant dimensions

(figure #2). Running sand and erratic

perched water tables are present in

the area. The typical soil is comprised

of a sequence of granular soils vary-

ing from silty sand to sand.

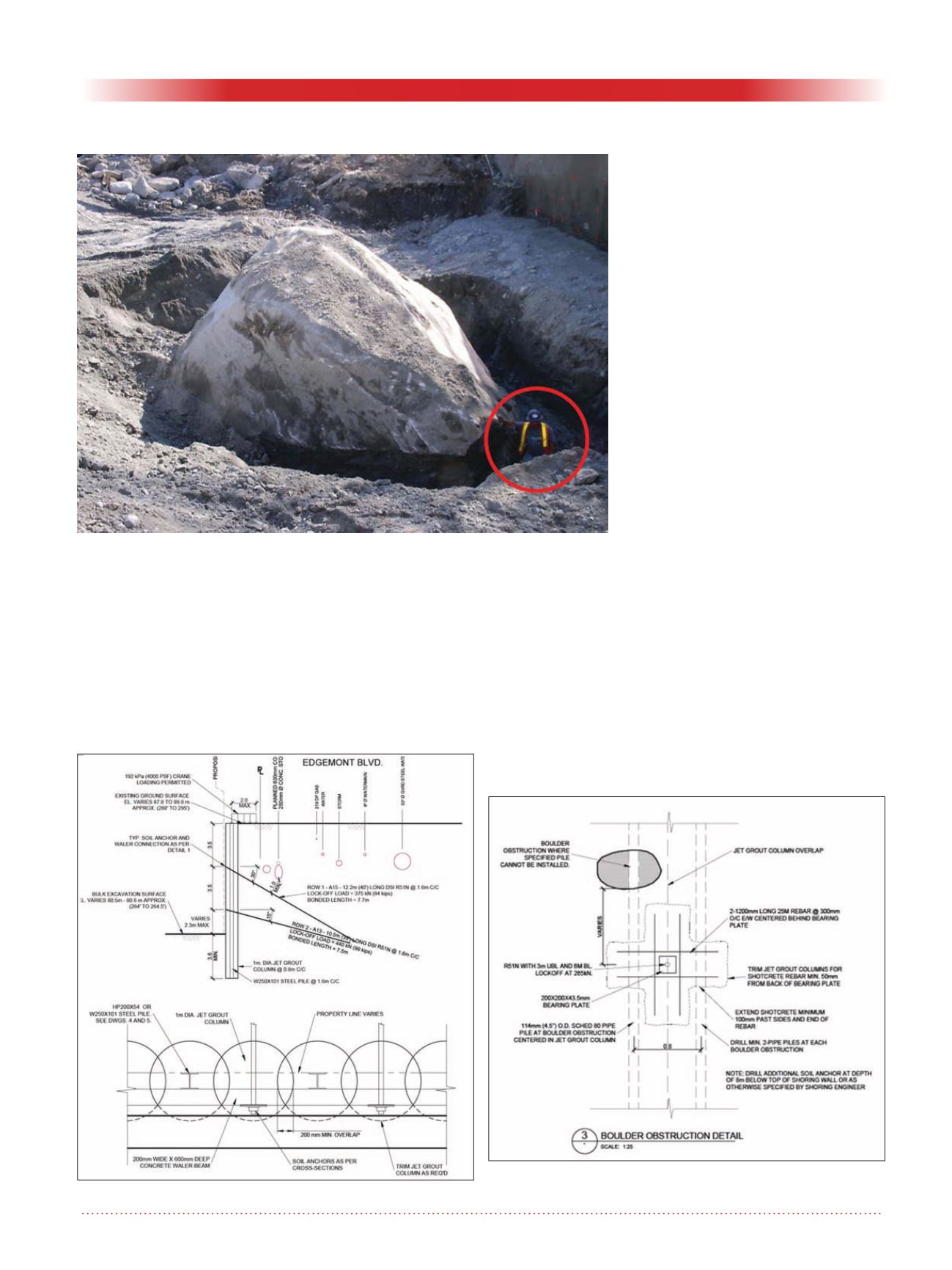

The original design and the jet

grouting alternate design

The original design called for a

secant pile wall solution with 1 meter

diameter piles, 0.8 m spacing and an

H-beam every third pile. Based on

the experience of previous excavation

projects in the North Vancouver area,

due to the presence of bouldery/cob-

bly soils, it was known that a secant

pile solution can be very expensive

and time consuming due to the neces-

sity of casing and coring/chiseling the

boulders with large diameter tooling.

Considering that jet grouting allows

for drilling of small diameter holes (5

to 6”) and due to success in similar

soil with this same technology, a

jet grouting solution was proposed

and accepted for the project by the

Owner.

Columns of 1 meter diameter and

steel H-beam were designed, similar

to the secant pile solution. Figure #3.

Figure 2: Erratic boulder in North Vancouver(!).

Figure 4: Boulder obstruction detail in case it was not

possible to install the designed H-Beam.

Figure 3: Typica jet grouted wall design.