Geotechnical News• December 2019

43

THE GROUT LINE

above the contact between rock and jet

grouting, in order to treat this transi-

tion zone with higher care.

In correspondence of the structures

founded directly on the bedrock, the

holes were drilled using as guides

some plastic tubes previously embed-

ded in the cast concrete.

The upper obturator bag was placed

about 1 m (3 ft) under the founda-

tion level, in order to obtain a sealed

contact between rock and concrete.

In this area a third alignment of pipes

was executed, inclined towards the

reservoir, in order to guarantee a better

treatment from the side of the hydrau-

lic head.

Final controls on the impervious

curtain

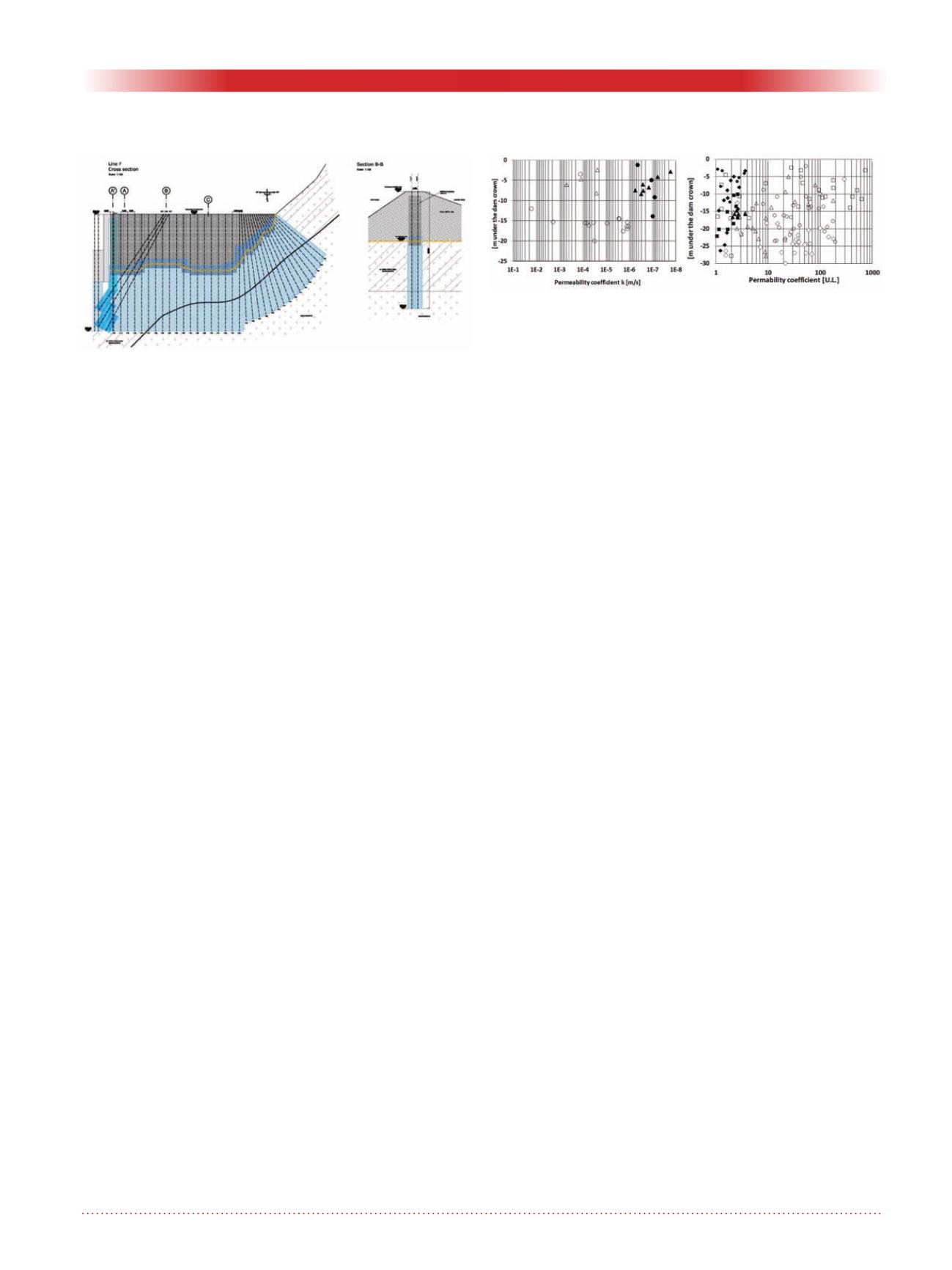

After the completion of the jet grout-

ing and rock grouting treatments, on

each site a final investigation cam-

paign was carried out. Lugeon and

Lefranc tests (rock and jet grouted

soil) were carried out on inclined

cored holes along the impervious

curtain and at different depths.

The tests always showed the fulfill-

ing of the prescribed permeability

coefficient, as plotted in the following

charts in fig. 13: the diagram on the

left shows the permeability values

before and after the jet grouting treat-

ment in the soil, whereas on the right

the permeability in Lugeon Units (UL)

before and after the rock grouting.

Permeability values after the treatment

are plotted with full symbols

Summary and Conclusions

The cascade HPP of Iskar River, in

Bulgaria, is composed of nine plants.

For each of them, the design required

the execution of a cofferdam for

protecting the power house excava-

tion site from the river flow, and of

an impervious curtain, along the earth

dam and the structures section, against

the water seepage in the ground,

composed of rock basement underly-

ing alluvial coarse soil. Until today,

five plants are completed and regularly

operating.

Jet grouting columns reinforced with

steel pipes were executed along the

provisional embankment in order to

make it waterproofed and to work as a

gravity structure able to withstand the

hydraulic effort of the water even in

case of floods. This solution allowed

to avoid any seasonal interruption dur-

ing the works in the riverbed, gaining

between 4 and 6 month in the execu-

tion schedule of each plant.

The impervious curtains have been

executed by combining the use of

jet grouting for the treatment of the

coarse soil layers, and the MPSP sys-

tem for the grouting of the underlying

bedrock. The adoption of the MPSP

allowed to save time during the treat-

ment of crushed rock and to obtain a

highly homogenous watertight treat-

ment, particularly sealing some critical

zones such as: the contact between

the rock and the jet grouted soil; the

upper part of the rock mass, weakened

from the excavations (usually made by

blasting); the contact between the rock

and the concrete foundation structures

of the power house and the weir. Final

permeability controls on site into the

curtains confirmed the good outcome

of the treatments.

Acknowledgments

A special acknowledgment to Pla-

men Dilkov, construction manager of

Vez Svoghe OOD that owns and has

built the plant, who directed the works

with the support of Patrick Pauletto,

to Achille Balossi Restelli and Elena

Rovetto who have contributed to the

development and the design of part

of the project, to Injectosond S.r.l.,

specialized company executor of the

treatments.

References

Balossi Restelli A., Rovetto E. and

Fava A. R., 1993. La tratta Dine-

gro – Principe della Metropolitana

di Genova. Atti del XVIII Con-

vegno Nazionale di Geotecnica,

Rimini (Italy), pp. 51-60.

Balossi Restelli A., Tornaghi R., Pet-

tinaroli A: and Rovetto E., 2003.

Reconstruction of La Fenice

Theatre in Venice – Foundations

problems. 13th European Con-

ference on Soil Mechanics and

Geotechnical Engineering, Prague,

Vol.2, pp. 29-34

Bruce D. A., and Gallavresi F., 1988.

The MPSP system: a new method

of grouting difficult rock forma-

tions. ASCE Conference, Nash-

ville, TN.

Manassero V., 1993. Different tech-

niques for soil improvement and

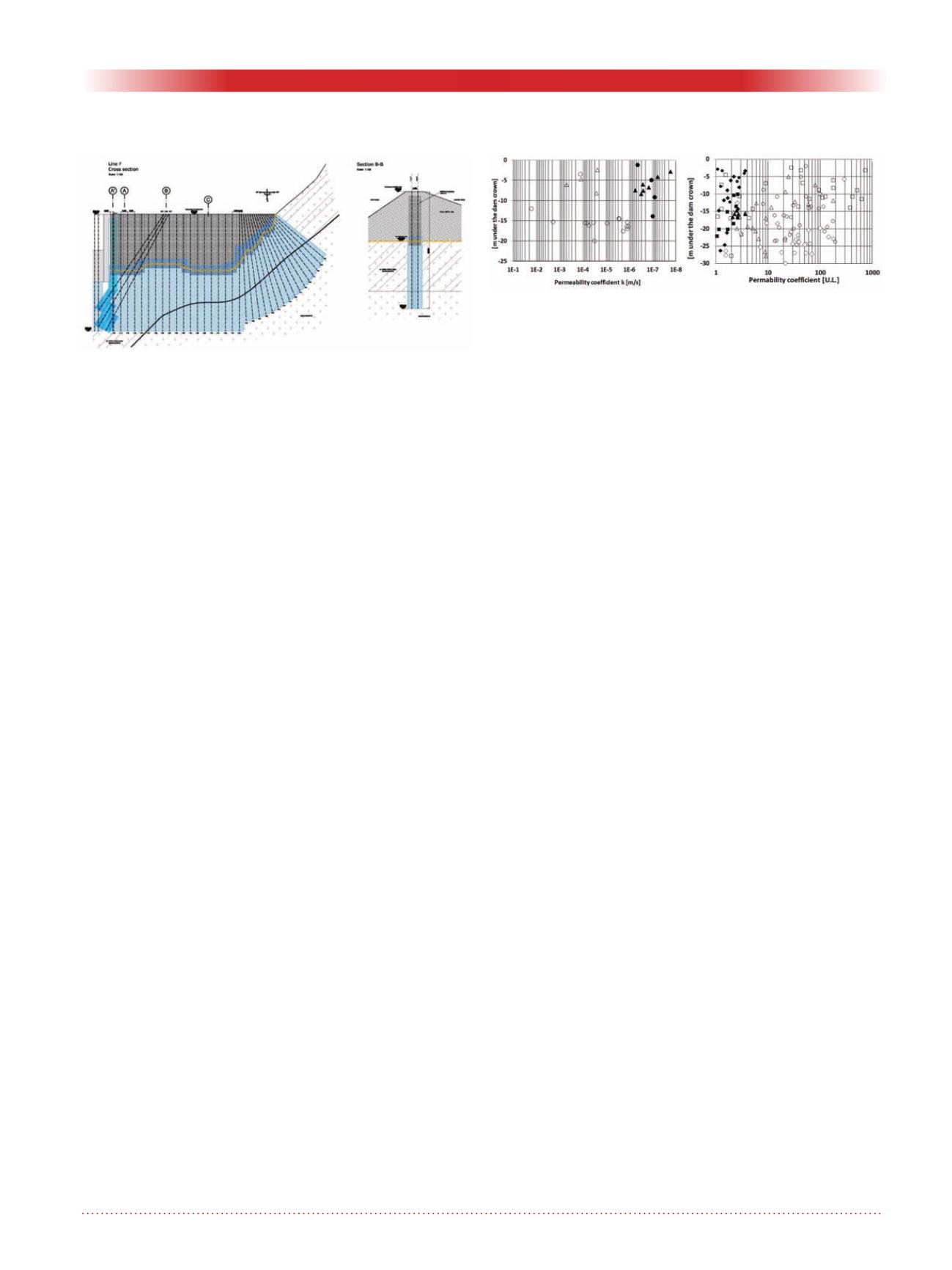

Figure 12: Cross sections of the treatment for the

impervious curtain along the earth dam.

Figure 13: Final controls on the impervious curtain:

Lefranc test in soil (on left), Lugeon test in rock (on right)

white and black dots. before and after the grouting.