Geotechnical News• December 2019

41

THE GROUT LINE

The setup of the geometry of the

three-dimensional model was per-

formed starting from the implementa-

tion of the 3D DTM (Digital Terrain

Model) of the area and assembling the

geometry of the dam structure accord-

ing to the proper design. Then, based

on the hydraulic properties of the

rocks and the soils affected by the dam

construction, which have been derived

from the results of the investigations

available, and the boundary conditions

assigned to the model, the continuity

equation governing the water seep-

age in the soil domain was integrated

in order to derive the values of the

hydraulic head for each node and

the values of the pore water pressure

accordingly. The main features of the

seepage regime consequent to the con-

struction of the dam were calculated in

order to design the impervious curtain

under the weir and the dam founda-

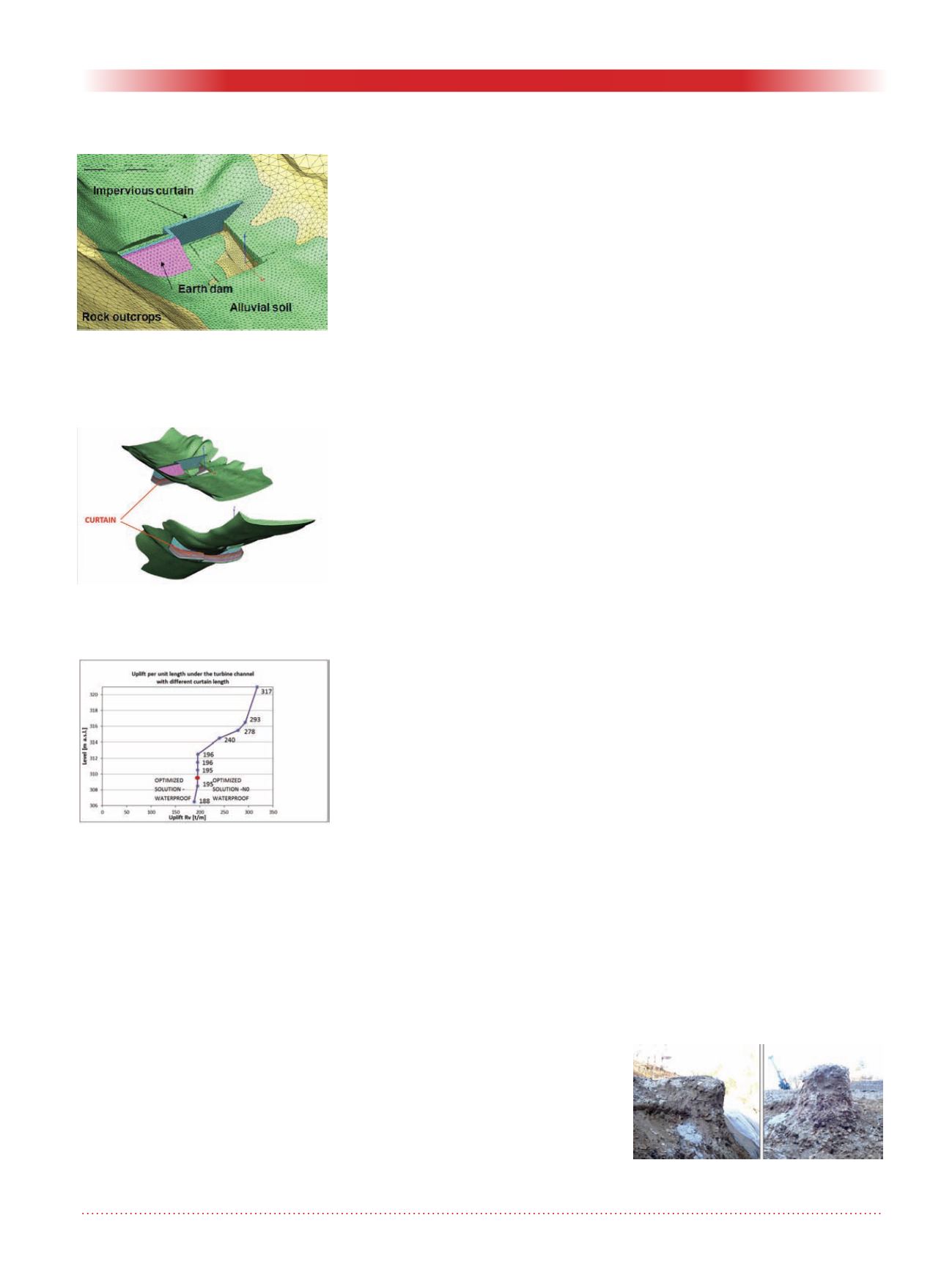

tion. A sensitivity analysis was carried

out taking into account different

values for the size of the impervious

curtain to assess the optimal length of

the same structure according to a cost-

effective solution (fig. 6 and fig. 7).

The impervious curtain

For all the plants the deepest excava-

tion level is placed in the area of the

power house, where the bedrock is

always uncovered. Hence the impervi-

ous curtain required to treat the most

surficial rock mass, all along the align-

ment, the coarse surficial deposit on

the sides of the section, and the earth

dam core.

The investigations showed that the

upper part of the bedrock was very

weathered with a thickness highly fis-

sured zone variable from 2 m to 5-6 m

and presenting very low RQD values.

The permeability values, measured

with Lugeon test, vary normally

between 3 and 50 Lugeon Units (UL),

and in several cases they can rise up

to 600 UL. According to the design

model, the target of the treatment for

the curtain was to not exceed 3 UL.

The alluvial formations were com-

posed of gravel and sand, in some sites

including 15-30% of silty fraction;

boulders were detected in the zone of

the current riverbed and in the flood

plain side areas, but normally only in

a surficial position. The permeabil-

ity, measured with Lefranc test, gave

results between 10

-4

to 10

-6

m/s (m/s =

3.2 ft/s) : the target after the soil treat-

ment in those strata and in the earth

dam core was fixed at 1-5x10

-7

m/s.

For the execution of the impervious

curtain, it was decided to treat the

soil with two lines of double fluid jet

grouting columns

Ø

1.30 m (4 ft), and

to grout the rock with cement mixes.

The curtain was carried out after the

execution of the earth dam, and, usu-

ally (but not always, due to the main

works scheduling), after the cast of

the weir and power house foundation

plate.

The critical issues of this solution

were hence:

• the locally highly fractured rock

in the transition zone to the upper

alluvial deposit

• the possible weakness of the jet

grouting treatment at the bottom

of the columns, in correspondence

of the contact with the underlying

rock

• the contact zone between the

ground and the concrete founda-

tions of the weir and the power

house, because of the surficial

disturbance of the rock due to the

excavation (made with blasting or

with non-explosive agent) and of

the discontinuity with the concrete

casts that need to be properly

sealed.

In order to obtain a homogeneous

treatment in all those critical zones, it

was decided to perform the rock grout-

ing by means of the MPSP (multiple

packer sleeve pipes) placed into the

holes that crossed the jet grouted soil

or the concrete foundations. MPSP

was chosen to avoid the risk of losing

packers, and consequently holes, in

the highly fractured rock.

The Ground Treatments

Jet grouting

Jet grouting columns were executed

as first, using air and a water/cement

ratio W/C =1 for the grout, injected

with a pressure of 40 MPa (5.8 ksi).

At the beginning of the activities, a

trial field was executed in order to

evaluate the result of treatment (see

Figure 5: The 3D model mesh.

Figure 6: A detail of the curtain

elements.

Figure 7: Sensitivity analysis of the

curtain depth.

Figure 8: Jet grouting trial columns

executed at the start of the works.