40

Geotechnical News • December 2019

THE GROUT LINE

Geotechnical investigation

The execution of several corings along

the main cross section of each barrage

allowed for reconstruction of the bed-

rock surface covered by the surficial

alluvial layer.

In each hole, permeability tests have

been carried out at different depths:

Lefranc tests into the alluvial soil

strata, Lugeon tests in the rock. Usu-

ally the corings put in evidence that

the upper part of the rock is rather

highly fractured. This information has

very often been confirmed and is bet-

ter proven by the Lugeon test results.

The cross section in Fig. 2 concerns

the plant of Lakatnik.

Power plant design

Each plant is composed by: the main

building that includes the intake chan-

nel, the turbine, the outlet channel, the

control hall; the weir with the gates;

the lateral earth dam (see fig. 1).

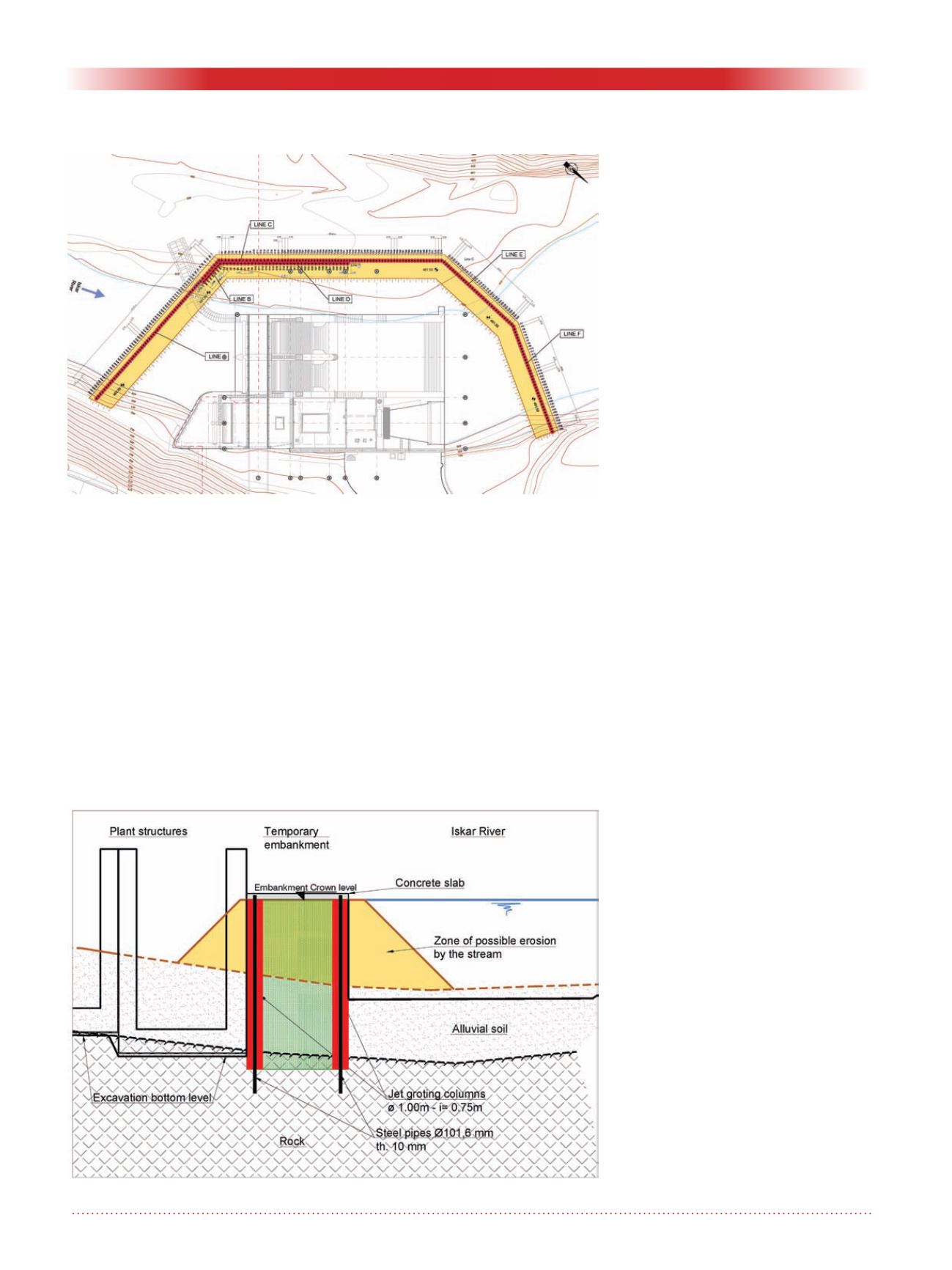

During the plant construction, an

earth embankment was built in order

to protect the front, the back and a

side site of the area from the river, as

shown in the following figure 3. The

embankment has been waterproofed

by executing, down to the bedrock

level, a line of temporary jet grouted

columns. This line of jet grouted col-

umns allowed for the execution of the

concrete structures and the installation

of the turbine and the electromechani-

cal devices regardless of the varia-

tion of the flow rate of the river: no

seasonal interruptions of the activities

were necessary.

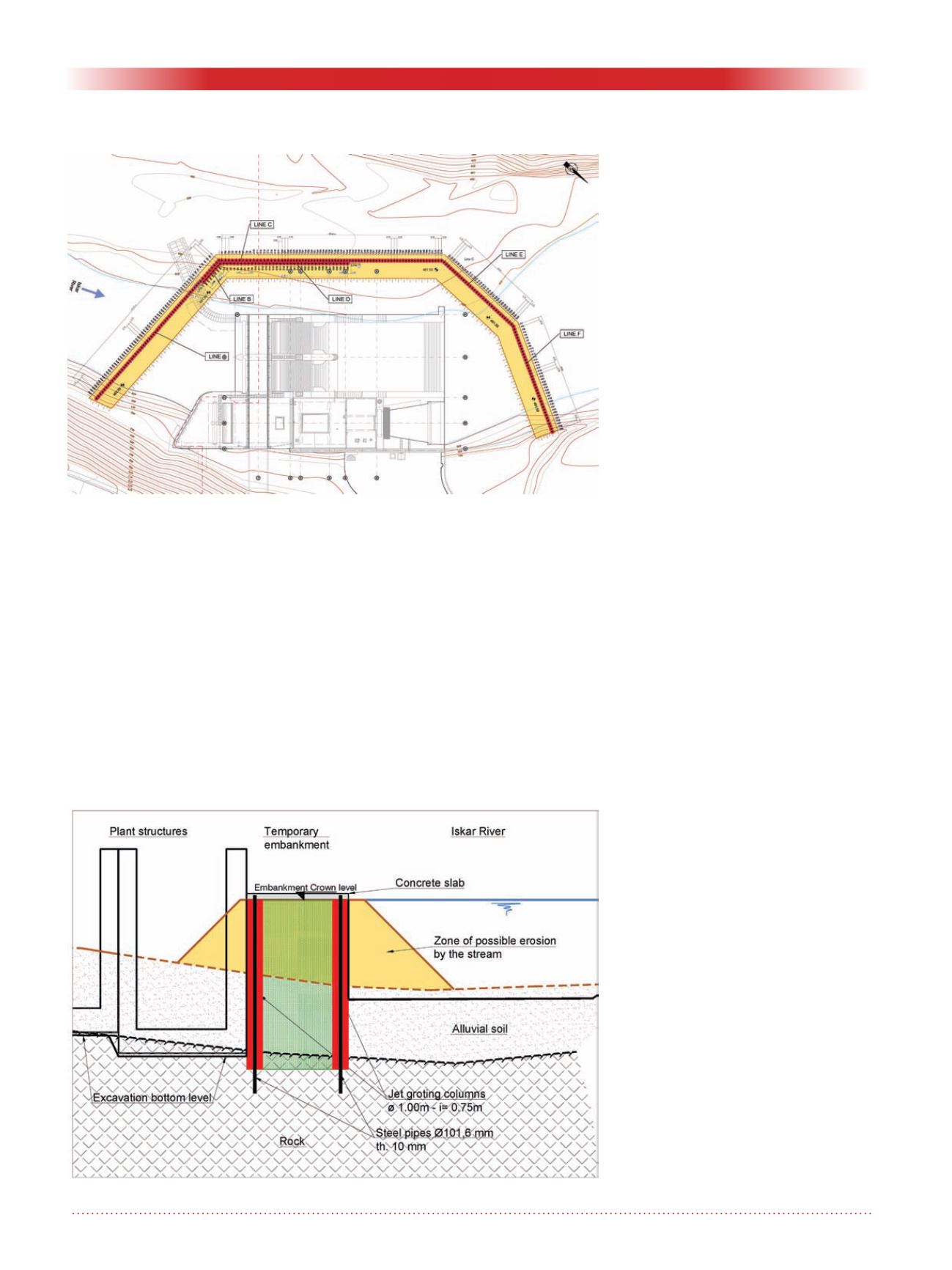

In some sites the plant lies in corre-

spondence of a narrow section of the

valley, so in order to guarantee the

necessary flowing section of the river,

the embankment was placed beside

the external alignment of the abut-

ment wall of the plant. In this case the

embankment has been considered as

a gravity structure, with two lateral

lines of jet grouting columns axially

reinforced with a steel pipe anchored

into the bedrock (see fig. 4).

The internal side of the embankment

has been excavated to uncover the jet

grouting columns; during the works

the grouted wall was protected with a

mesh of reinforced shot concrete, until

the cast of the abutment wall finally

covered the vertical surface. The

reinforcements were designed taking

into account that the water flow might

remove the slope of the embankment,

and considering the hydraulic load

applied to the remaining treated core

with the deeper level reachable during

the plant excavation. So the reinforced

double jet grouting sheet has a double

function: to assure the equilibrium of

the embankment and to protect it from

the erosion by the river water.

For each plant a FEM analysis of the

steady-state seepage process following

the construction of the dam and hence

the presence reservoir was carried out

by applying a three-dimensional finite

element code (Fig. 5).

Figure 3: Cofferdam as protection of the site during the activities in case of

river flood.

Figure 4: Cofferdam reinforced with jet grouting columns and steel pipes.