42

Geotechnical News • December 2019

THE GROUT LINE

pictures in fig. 8) of the discovered

columns) and to set up the operational

parameters (flow rate and pressure of

grout and air, uplift velocity, rotational

speed) after the treatment energy pro-

cedure (Tornaghi et al. 2004).

In order to allow a more regular high

pressure injection during the uplift

phase, even in presence of boulders,

each column execution was preceded

by a predrilling, carried out 1 m down

into the bedrock, by means of a dedi-

cated drilling unit.

Some preliminary pre-drillings along

the columns’ alignment (for the cof-

ferdam as well as for the impervious

curtain) were initially made, in order

to detect the bedrock level and hence

to draw an accurate profile of the allu-

vial deposit base.

The geometry of the treatment

involved the execution of inclined

columns at the two ends of the curtain,

with drillings made with angles up to

43° from the vertical.

During the treatment of the cofferdam,

the steel pipe reinforcement was usu-

ally inserted in the hole made for the

jet grouting.

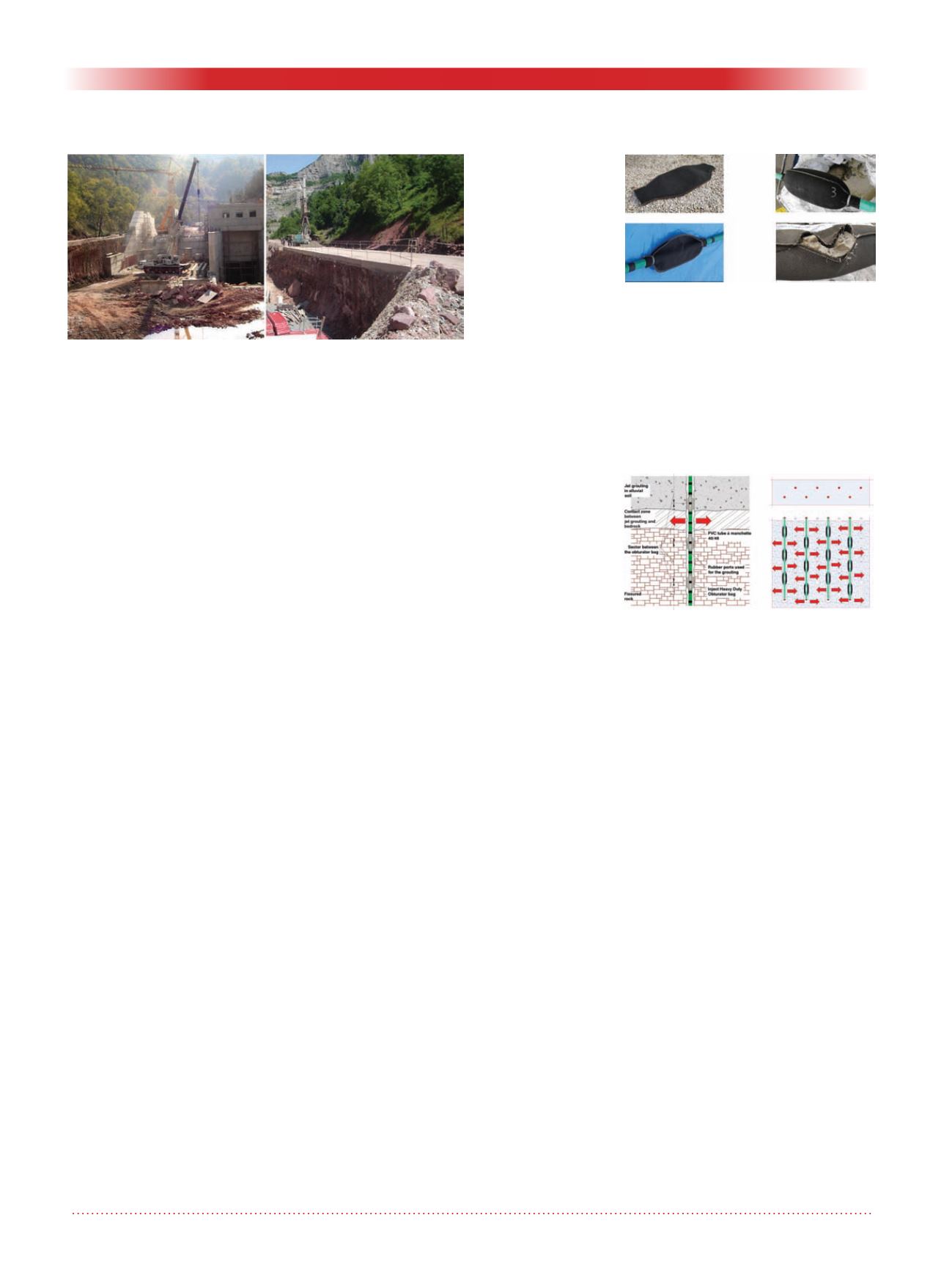

The effect of the treatment was suc-

cessfully tested during the excavation

for the plant construction. The picture

in fig. 9 shows on the left the jet

grouted wall that separates the

riverbed from the area of the site

for the power house and the gates

building. No significant water income

from the waterproofed embankment

occurred.

On the right –

The road on the

crown of the

embankment,

used for the site

traffic

This allowed for

completion of

all the activities

for the power

plant construc-

tion (from the

embankment con-

struction to the test on the turbine) in

18 months without any interruption. In

case of seasonal interruption (without

the waterproofing of the cofferdam),

6 additional months should have been

considered. Until today, during the

works for the five plants completed,

only on one occasion the river has

overflowed the embankment, causing

a flood that interrupted the works. The

site was evacuated on time, thus limit-

ing the damages. Two months were

necessary for restoring the yard.

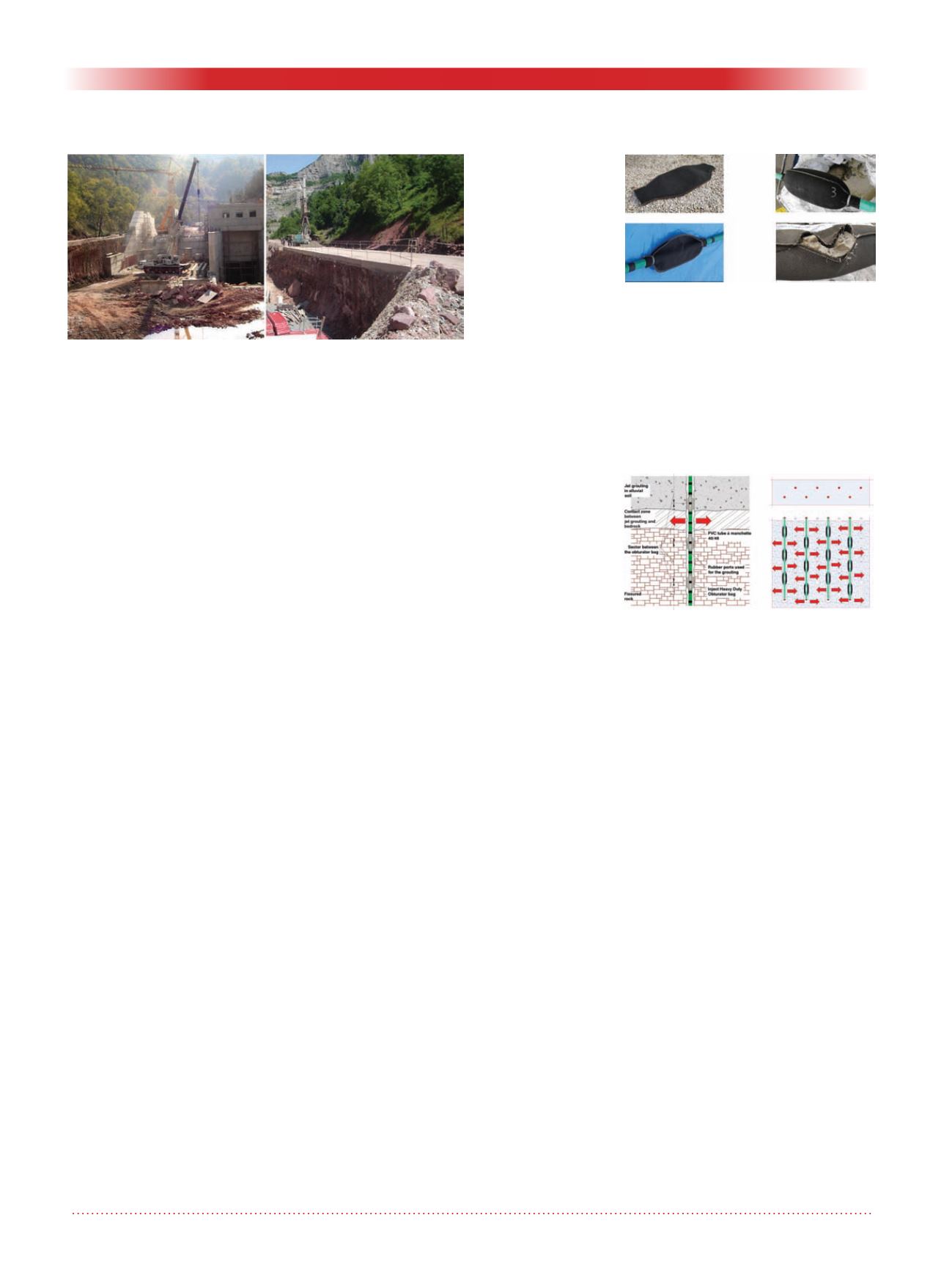

Rock grouting

The treatment of the rock for the

impervious curtain was carried out

using the MPSP (Multiple Packer

Sleeve Pipe) system. After the hole

was drilled, a

Ø

1”1/2 PVC TAM

pipe (40/48 mm inner/outer diameter)

was installed. The TAM pipe was

equipped, every 3 to 5 meters, with

several Heavy Duty Obturator Bags,

made in polypropylene geotextile and

mounted on one or two sleeves. The

bags were initially folded and fixed to

the pipe at the ends by a metallic tie

(see fig. 10). The tube was centred by

means of plastic collars.

Once the pipe was in place, the bags

were filled with injected cement grout

(ratio W/C=0.6:1) by a double packer

lowered to one of the correspondent

sleeves, and finally sealing the annular

space between the plastic pipe and

the borehole. Under the pressure of

the injection, the cement of the grout

separated from the water, being the

latter ejected per seepage through the

geotextile. As a result, the hole was

divided into several stages by means

of the tough sealings obtained inject-

ing each obturator bag; a curing time

of 18-24 hours were sufficient for the

aim (see fig. 11).

The grouting of each stage was then

made with the conventional MPSP

injection procedure. The double

packer was placed astride one of the

sleeves of the deeper sector, but in this

case no plastic sheath was necessary.

In fact, the grout filled initially the

annular void between the pipe and the

borehole, and then it flushed into the

fissures intercepted by the hole stage.

The injection was then carried out

following the prescribed rules for

the rock treatment. The curtain was

formed by two alignments of TAMs,

spaced 1.50 m (5ft) and with interaxis

of 1.50 m (5ft) between the boreholes.

In a first phase primary pipes were

drilled and injected; then the second-

ary pipes phase followed (fig. 12).

Along the earth dam axes the holes

were drilled passing through the jet

grouted columns.

The obturator bags were installed

every 3 to 5 m (10 to 16 ft) in the pipe

stretch into the rock to be treated.

Another bag was mounted about 1 m

Figure 9: On the left - Works in progress with the jet

grouting wall protection from the river bed.

Figure 10: Folded and injected

obturator bags mounted astride a

manchette.

Figure 11: Scheme of the MPSP

system grouting.