Geotechnical News June 2011

45

WASTE GEOTECHNICS

successful,” says Lahaie. “We have a

large data set overlaid by many years’

worth of information. David can man-

age and work amongst all the data and

simplify it into useful metrics. On top

of that, he has a lot of practical knowl-

edge. He marries the two in a very utili-

tarian way.”

Carrier is currently working on

accelerated dewatering methods at

Syncrude’s Mildred Lake project near

Fort McMurray with Jack Seto of BGC

Engineering Inc. and Murray Fredlund

of SoilVision Systems Ltd. Carrier,

who conducted notable rim ditching

research in Florida, believes Terzaghi’s

effective stress principle can be applied

to the soft, yoghurt-like fine tailings.

“We needed to change the framework

and see this as a mechanistic process

rather than a chemical one,” says Car-

rier.

The combination of rim ditching

on the perimeter of the deposit with

evaporation on the top of the deposit

will increase the effective stress, creat-

ing a landform with greater trafficable

strength. According to Carrier, the key

is to drain the water off so that it can

evaporate and crack. Water draining

and surface cracking will lead to the

lowering of the water table, which ap-

plies a larger load on the layers under-

neath. “You leave it for a year and then

come back to cut a bit deeper around

the perimeter. Then leave it again for

year. You keep doing this until the soil

is dense enough that you can reclaim it

and pour sand on it or plant vegetation

on it,” he says.

Though the methodology is rela-

tively simple, Carrier says the primary

concern is getting the produced tail-

ings into a manageable volume. Then,

the next question is how to make it

stronger. Carrier believes all the tech-

nologies that the industry is looking at

now, such as centrifuging and thin-lift

deposition, will result in denser, more

manageable, more environmentally

friendly and sustainable material. Yet

he is quick to point out that dewater-

ing is not without its challenges. “The

more densification we do, the more

water we produce within the system,”

he says. “The long-term challenge for

the industry is reducing the volume of

water stored and ensuring the reclama-

tion of it.”

Carrier’s experiences prove that the

sky is certainly not the limit when it

comes to tackling tailings issues. The

rim ditching research done by Car-

rier and his Florida colleagues has

resulted in the reclamation of 50,000

hectares (500 km

2

) of phosphatic clay

ponds. Currently there are 426 km

2

of

disturbed land in Alberta’s Athabasca

region. In an effort to conduct collab-

orative research on the early reclama-

tion of tailings ponds in Alberta, the

Canadian Oil Sands Network for Re-

search and Development (CONRAD)

Carrier working at a test pit with baux-

ite tailings in the Amazon jungle of

Brazil.

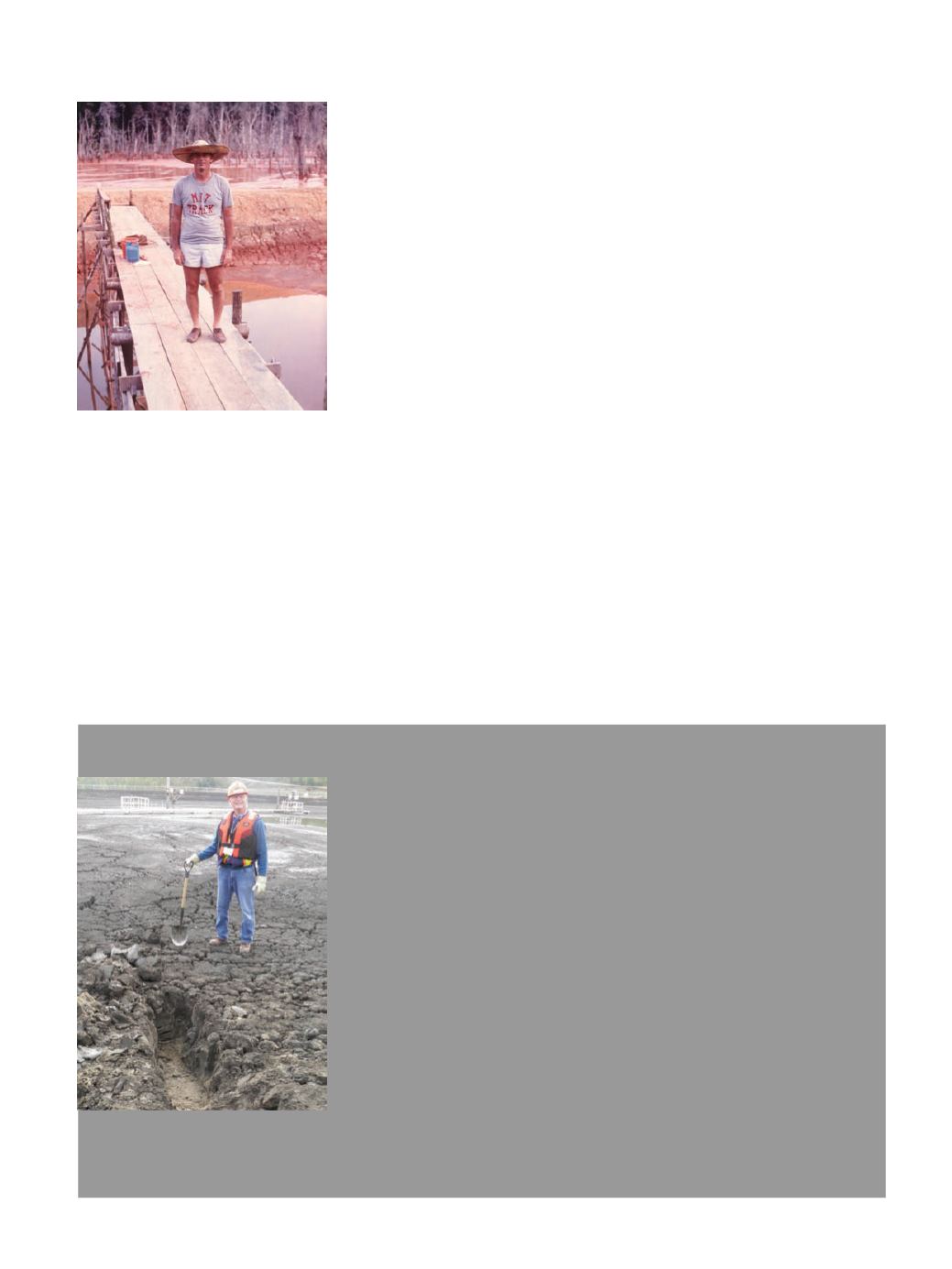

Digging Towards Success

David Carrier is standing on crusted oil

sand flocculated fluid fine tailings after

one year of dewatering at the Syncrude

Canada Ltd. Flocculated Fluid Fine

Tailings Perimeter Ditch Dewatering

Pilot Project at its Base Lease

Operations north of Fort McMurray,

Alberta.

Carrier is standing on the edge of

flocculated fluid fine tailings (a “silty

clay” flocculated with polymers) that

have been deposited in an impound-

ment approximately 80 m by 80 m by

10 m deep and is dewatering mostly

by surface evaporation and water flow

to a progressively deepened perimeter

ditch that is connected to a drain. The

perimeter ditch concept is patterned af-

ter similar work that Carrier has been

involved in Florida with dewatering

clays from the phosphate industry.

Carrier is wearing a life jacket and is

being very careful not to break through

the crust that he is standing on and into

underlying fluid-like tailings below the

crust that has not yet dewatered. Where

he is standing, there is approximately a

20 cm crust on about 1 m depth of fluid

fine tailings.

Note the surface-cracking network

that has developed due to shrinkage of

the material as it dewaters. The ponded

water behind him in the center of the

Pilot deposit is from recent rains. This

water has not yet either evaporated

or found its way through the surface-

cracking network and perimeter ditch

to a drain where it is removed from the

Pilot.

The floating dock way and geo-

technical instrumentation poles (pi-

ezometers, thermistors, and settlement

gauges) behind Carrier are in the center

of the Pilot. The fence around the pe-

rimeter of the Pilot keeps animals and

people from wandering into the Pilot.

— Geoff Halferdahl, Syncrude Canada

Ltd.