40

Geotechnical News June 2011

THE GROUTLINE

sure sets, especially those verti-

cally oriented. The zone between

these “outer rows,” typically about

10 feet wide, is then available for

additional “tightening” holes, per-

haps using special or different

grouting materials, and for drilling

and testing Verification Borings

which are installed to demonstrate

the residual permeability achieved

by the curtain.

• Residual Permeability:

The pur-

pose of a grout curtain is to stop

water flowing through the rock

mass. Therefore, its acceptability

as an engineered structure must be

verified by measuring its residual

permeability — to water, not some

arbitrary limiting grout take. (As

described above, an inappropriate

grout will have premature refusal

in certain fissures, while not reduc-

ing the permeability of the ground

further away.) This test is best done

in cored (or Optilogged) holes, us-

ing multipressure Lugeon Tests as

first described by Houlsby (1976).

• Declaring the Target Residual

Permeability:

Residual permeabil-

ity is the goal which must be de-

clared as part of the design by the

Engineer and which therefore must

be satisfied by the Contractor. A

grout curtain truly now is a “Quan-

titatively Engineered” structure

(Wilson and Dreese, 2003), created

by real-time control of subsurface

construction processes. This “mea-

sure of success” will vary from

project to project, as articulated by,

for example, Houlsby (1990), but

is vital to declare and essential to

satisfy.

• Stage Refusal

: Each and every

stage should now be brought to a

virtually total refusal. When view-

ing the grouting process on the

computer monitor, this means an

Apparent Lugeon Value of practi-

cally zero for each stage (i.e., the

(stable) grout is used as a test fluid

in the same way as water is). In

reality, this means that the stage

in question is consuming grout at

less than 0.1 gpm over a period of,

say, 5 minutes, at target pressure.

More lax refusal criteria will result

in incompletely and inefficiently

grouted stages, and so higher than

desirable residual permeabilities in

the rock mass.

• Drilling Methods and Concepts:

Water is the drilling and flushing

medium of choice in rock masses.

Whether the drill-

ing is done by

percussive meth-

ods (top hole, or

water-powered

down- t he -ho l e

hammer) or ro-

tary

methods

(which tend now

to be less com-

petitive and have

greater

devia-

tions) is techni-

cally

immate-

rial. Also, the

development of

commercially vi-

able rotary-sonic

systems (Bruce

and Davis, 2005)

has provided a

method

which

has entirely satis-

fied federal regu-

lations (USACE, 1997) for drilling

through existing embankment dams

without fear of hydro or pneumatic

fracture. In this regard, it is also

the case that innovative contractors

can devise other conforming over-

burden drilling systems which are

equally protective of embankment

fills (Photograph 3).

In all drilling operations, the recording

of drilling parameters (e.g., rate of

penetration, flush characteristics,

torque and so on) has been regularized

by developing automatic recorders as

opposed to relying on drillers or junior

field engineers: the overall rise in the

quality and usefulness of these data has

been predictably spectacular.

• Specifications and Contractor

Procurement Processes

: Specifi-

cations are no longer so prescrip-

tive (“yes: we do need the head of

the contractor as well as his arms”)

and so all contracts are not let on

the low bid basis, although to do

otherwise is still not permissible

for many organizations, especially

in the public sector. Grouting con-

tractors are being hired, correctly,

based on their skills and experi-

ence and not just their capability

of calculating a low price. There is

absolutely no doubt that this “Best

Value” approach has raised techni-

cal standards across the board and

has, interestingly, honed the com-

petitive instincts of all competent

contractors: all this is to the inesti-

mable benefit of the projects them-

selves. Further insight on specifi-

cations is provided in Bruce and

Dreese (2010).

Retrogressive Principles (i.e.,

“The Retrogressive”)

The fact is that certain engineers in

North America have become involved

in projects where a certain expertise

in curtain grouting is needed and

where, for commercial reasons, they

have chosen to go their own way,

and/or to “reinvent the wheel.” The

uncomfortable truth is that they

are either not aware of the “new”

approach, or do not have the technical

background to be able to differentiate

its value in comparison with older

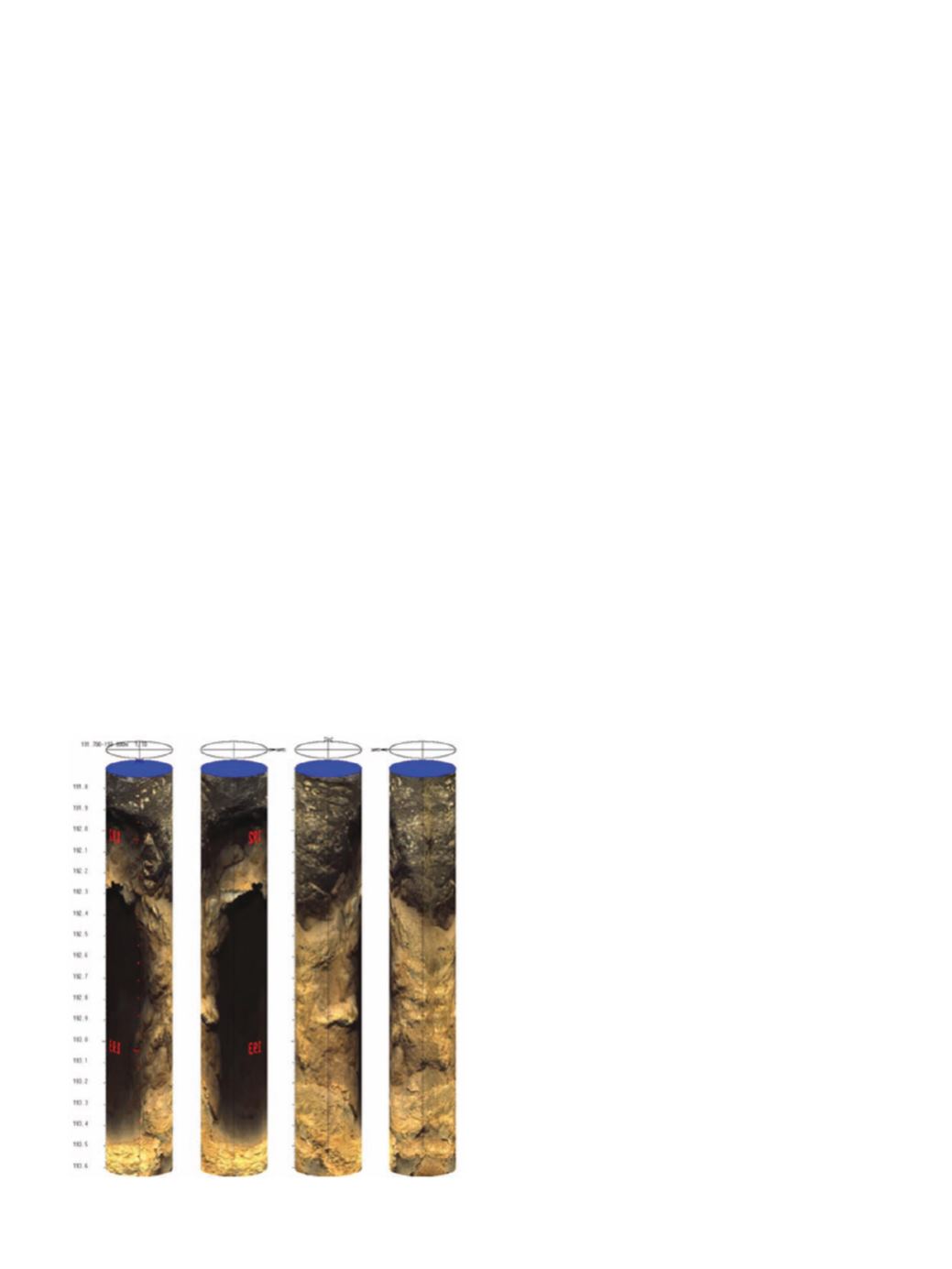

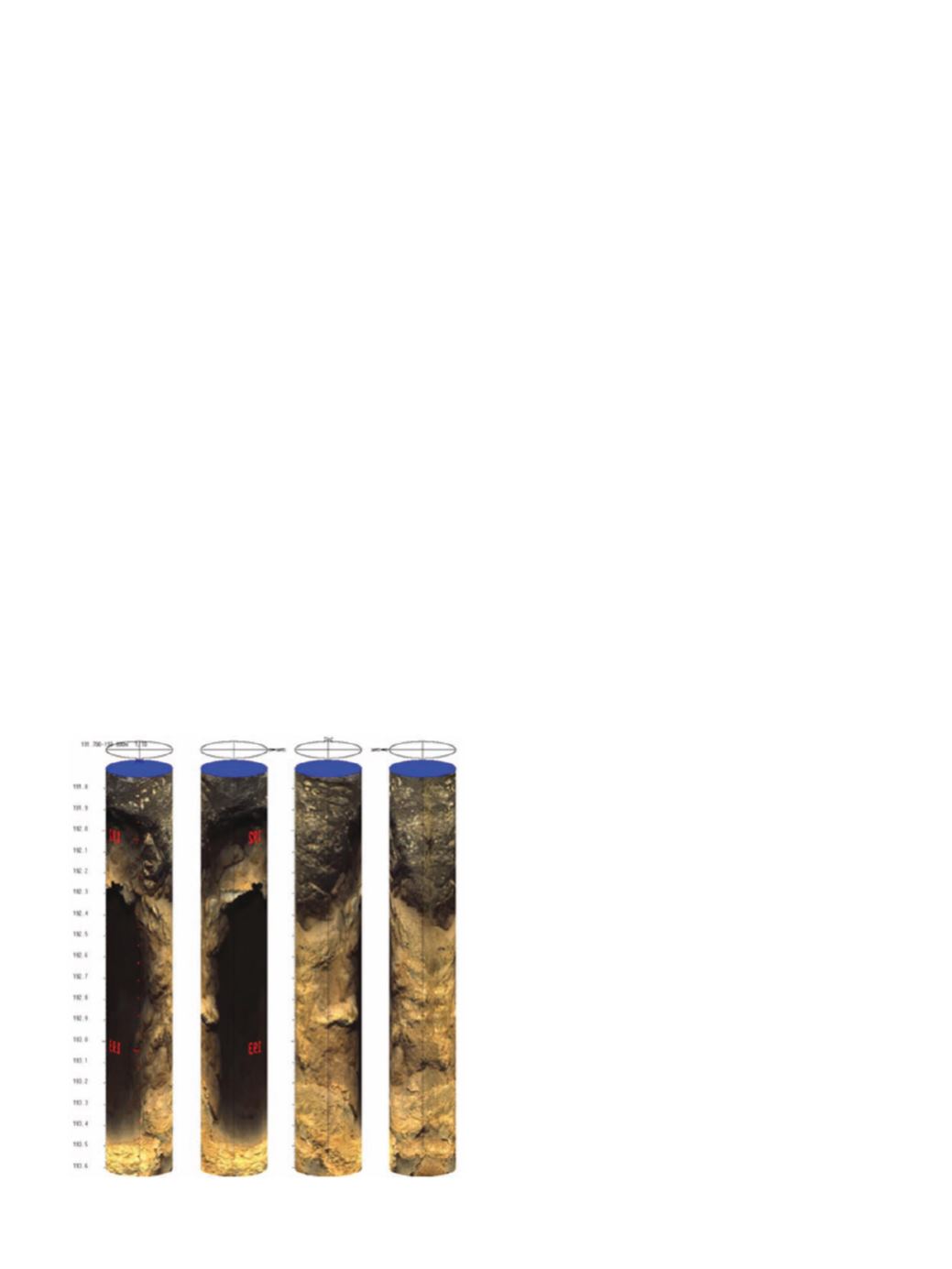

Photograph 2. (Courtesy of ACT and Gannett Fleming, Inc.).