Geotechnical News June 2011

39

THE GROUTLINE

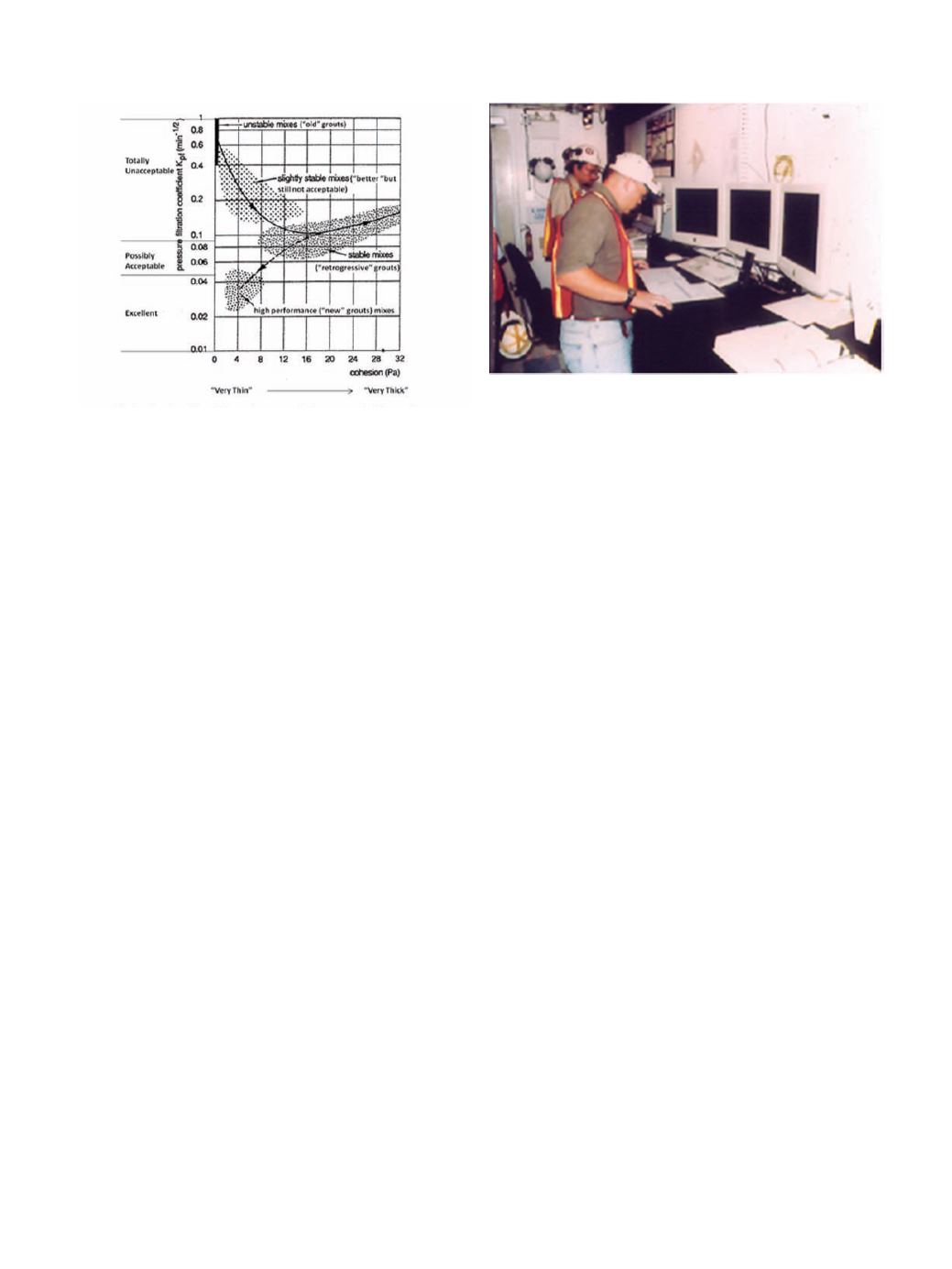

in Figure 2. Whereas cohesion was

traditionally minimized in simple ce-

ment–water grouts by using extremely

high w:c ratios (Albritton 1982), such

mixes have high Kpf values, which

severely curtail their penetrability.

However, by using much lower water

contents (typically less than 1.5 weight

by volume) and combinations of stabi-

lizing and plasticizing admixtures and

additives (including bentonite, silica

fume, and Welan Gum), grouts of low

viscosity (less than 60 seconds Marsh),

low cohesion, minimal bleed, and ex-

cellent Kpf values (less than 0.02 min–

1/2) can be produced. DePaoli et al.

(1992) found that even under moder-

ate injection pressures, such balanced,

stabilized grouts provided enhanced

penetrability and performance via the

following:

• an increased radius of travel;

• a more efficient sealing ability as a

result of the improved penetrability

and the lower permeability of the

mix;

• a high volumetric yield, with uni-

formly filled voids; and

• a higher erosion resistance because

of improved mechanical strength

for a given cement content.”

Of course, it must be acknowledged

that other factors will impact curtain

effectiveness, but never in the

U.S. literature before 1992 was the

significance (or even concept) of

“pressure filtration” mentioned in

conjunction with

rock grouting.

It is only fair

to separate from

the comparison

between “old” and “new” those ele-

ments which are, by invention and

technology, the exclusive privilege of

the “new.” Much has been written and

rightly so, about the tremendously ben-

eficial effect that the use of computer-

based systems have had on the col-

lection, processing, interpretation and

display of data from the field (Dreese

et al., 2003). No reputable grouting

project of any significant scale or im-

portance does now not have such a ca-

pability, feeding news back into a cen-

tral “mission control” (Photograph 1),

and back into the Project Executive’s

desk in head office, as well. The best of

these systems can now integrate all the

drilling and water testing data, as well

as the grouting data, to compliment and

compare with the historical site inves-

tigation data (and original grouting in-

formation) which may be available on

any particular project. Given the power

of this knowledge, curtains can be con-

structed to engineered standards with

a degree of reliability and confidence

which was unthinkable under old re-

gimes.

Another child of the new age is the

Optical or Accoustic Televiewer, an ex-

tremely acute and reliable instrument

which basically provides a “flat core”

of a preexisting hole (Photograph 2).

With this capability, the borehole wall

conditions of drill holes — formed

“destructively” without the expense of

core drilling — can be closely scruti-

nized, and compared with results from

permeability tests and grout injections.

This is an extremely important diag-

nostic tool, and represents a compat-

ibility far beyond the grainy, boring

images hitherto provided by down-the-

hole video cameras.

Returning to a comparison of “old”

and “new” concepts, the fundamental

change in attitudes towards mix de-

signs and mix properties has already

been discussed: it is one absolutely

vital component in the revolution.

However, even today, the author finds

specifications — or worse, projects —

where the grout mix design comprises

three components at best, and mixes

are changed from “thin” to “thick” by

changing from water:cement ratios

of 3:1 to 0.8:1, or 0.6:1 in the case of

“gulpers.” This is simply inexcusable

and not acceptable given the state of

knowledge which currently exists and

is freely available on this subject.

Other areas of important distinction

in contemporary grout curtain design

and construction may be summarized

as follows:

• Curtain Geometry:

Curtains must

have, as a minimum, 2 rows of

holes, which extend, wherever fea-

sible technically, into a confining

layer. They are not simply installed

to a target depth below ground

surface. Also, the holes in each

row are inclined say 15º off verti-

cal. The inclination of each row of

holes is in the opposite direction,

thereby producing a “criss cross”

effect, assured to intercept all fis-

Figure 2. Historical path of development from unstable mixes

to contemporary balanced multi-component mixes (modified

after De Paoli et al., 1992).

Photograph 1. (Courtesy of ACT and Gannett Fleming, Inc.).