38

Geotechnical News June 2011

THE GROUTLINE

sion drilling was then synonymous

with the use of air flush, which

many (but not all) did recognize as

detrimental to fissure cleanliness

and amenability to grout. (The age

old debate about rotary versus per-

cussion drilling as being more suit-

able for grout holes was wrongly

focused: it should have been water

versus air.)

• The concept of a “one row curtain,”

except notably under the cores of

embankment dams, where even

then the shallowest possible excuse

was taken to revert to one row.

• The use of relatively low grout pres-

sures, resulting from the recurrent

specification to provide “constant”

pressures which therefore meant

the use of progressive cavity pumps

(“Moynos”) as opposed to higher

pressure piston or ram pumps.

• The use of “thin” grouts (with ex-

cessive water:cement ratios often

well in excess of 10 by weight – al-

though typically mixes were mea-

sured by volume). Such mixes of

course were easy to pump due to

their low apparent viscosity, but

naturally had extremely high bleed

values and horrible pressure filtra-

tion resistance. These mixes were

allied with a fundamental distrust/

unawareness of the benefits of ad-

ditives (except for calcium chlo-

ride in “taker” situations) although,

latterly, the use of bentonite was

entertained and ongoing though

somewhat misguided experimen-

tation with superplasticizers was

conducted in certain quarters.

• Curtains were grouted until a cer-

tain cement refusal was obtained

(e.g., 1 bag per foot) as opposed to

a measured residual permeability.

This is, however, a charitable view:

often the grouting was discontin-

ued when the budget was expend-

ed and, in the aftermath when the

underseepage became of alarming

quantities, the cry was made that

“the grouting didn’t work!” The

general result (Weaver and Bruce,

2007) of these deficiencies was

either a) a poor travel of grout in

the ground, leading to the drilling

of families of higher order holes

at ridiculously close centers (e.g.,

1 foot at Chickamauga Dam, TN),

or b) uncontrollable flow of “thin”

grouts into karstic voids or similar

major features.

It is somewhat of a testament to

the enlightened, the lucky, and the

meticulous that so many of the curtains

constructed in the period from the

1920’s to the early 1980’s in particular

appear to have actually functioned

adequately given the restrictions, the

misconceptions and the prescriptions.

Uncharitable views would have it

that such curtains may not have been

needed at all, from a dam performance

or safety viewpoint, and that the curtain

was inserted by rote and by paradigm.

On the other hand, the fact that so

many of our dams have now been

remediated, or are facing remediation

as a result of an ineffective, incomplete

and/or deteriorating grout curtain, does

lead us back to the inescapable fact that

the “old ways” in retrospect contained

major flaws in their workings. One

definition of the word “insanity” is

to continue to do the same thing even

when it has been repeatedly proved to

fail or to be wrong. To persist with, or

revert to, the “old” ways of grouting

dam foundations is an example of this

definition.

Current Principles (“The New”)

There had arrived in theNorthAmerican

scene by the mid-1990’s a potent

mixture of knowledge and opportunity.

As arguably first articulated at a

Grouting Seminar

in

Toronto,

ON in 1989,

but

certainly

emphasized

to

the cogniscenti

in New Orleans

in 1992, the

world of dam

grouting in North

America

had

begun to change

d r a m a t i c a l l y.

This statement

is made with all

due recognition

of Dr. Wally

Baker who, some

years before, had instigated an advance

into new technical fields, but an

advance which proved economically

unsustainable in the face of prevalent

contracting and procurement vehicles

of the time.

Of particular significance was a pa-

per by DePaoli et al. (1992) which, in a

deceptively understated way, explained

quite clearly the critical control and

importance of pressure filtration coeffi-

cient over the effective travel of grouts

into fissures, and hence their efficiency

in generating low and durable residual

rock mass permeability. As described

in Weaver and Bruce (2007), pressure

filtration can be conceived as follows:

“The injection of particulate grouts

into small apertures is similar to press-

ing the grout against a filter material:

depending on the formulation of the

grout, water can be expelled from the

grout in motion, leading to the devel-

opment of cementitious filter cake at

the borehole wall. With more time, the

cake blocks off the entrance to the ap-

erture and so renders the aperture inac-

cessible to further injection via that av-

enue. This tendency of the grout to lose

water during injection is quantified by

the term

pressure filtration coefficient

(Kpf)…”

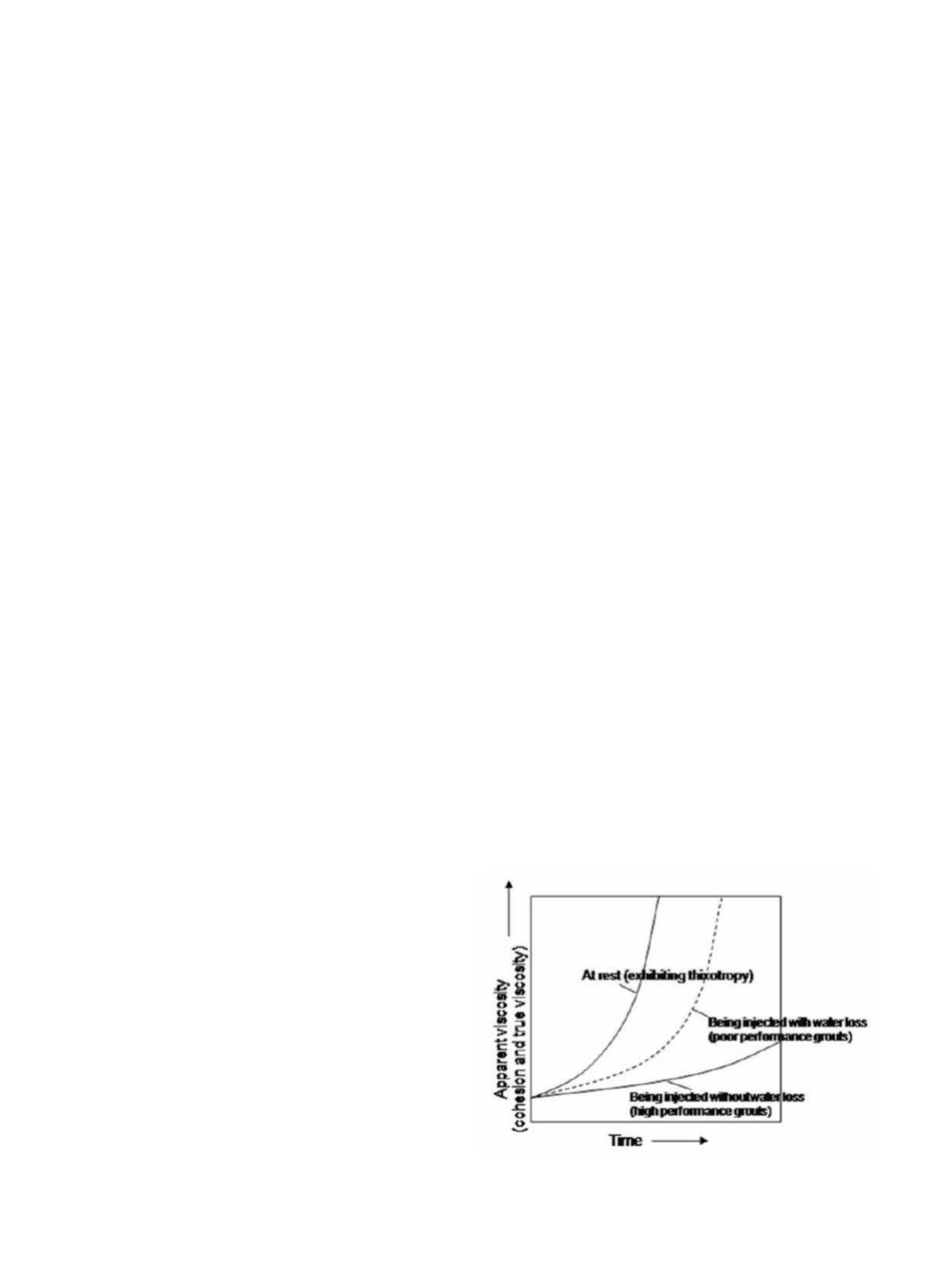

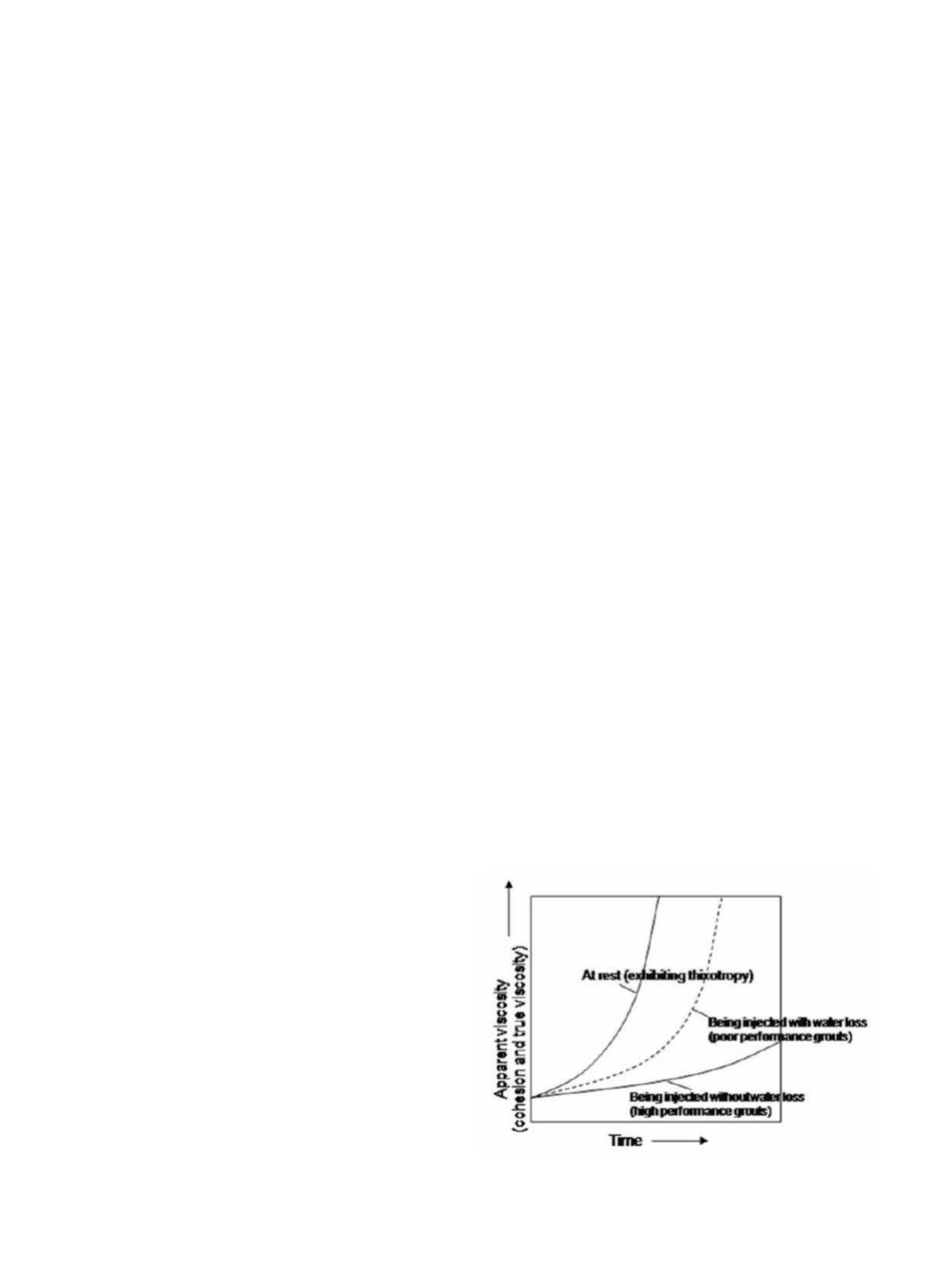

“To enhance the penetrability of a

grout, a low-pressure filtration coeffi-

cient that minimizes the increase in ap-

parent viscosity (Figure 1) is required.

The general relationship between the

two vital parameters of cohesion and

pressure filtration coefficient is shown

Figure 1. Rheological behavior of typical Binghamian fluids

(modified after Mongilardi and Tornaghi, 1986).