30

Geotechnical News • March 2012

GEOTECHNICAL INSTRUMENTATION NEWS

Remote monitoring of surface deformation with Robotic Total

Stations using reflectorless measurements (RRTS)

Damien Tamagnan and Martin Beth

[Please refer to Tamagnan and Beth,

GIN Sept 2011, pp 21-24 for more

details. Ed.]

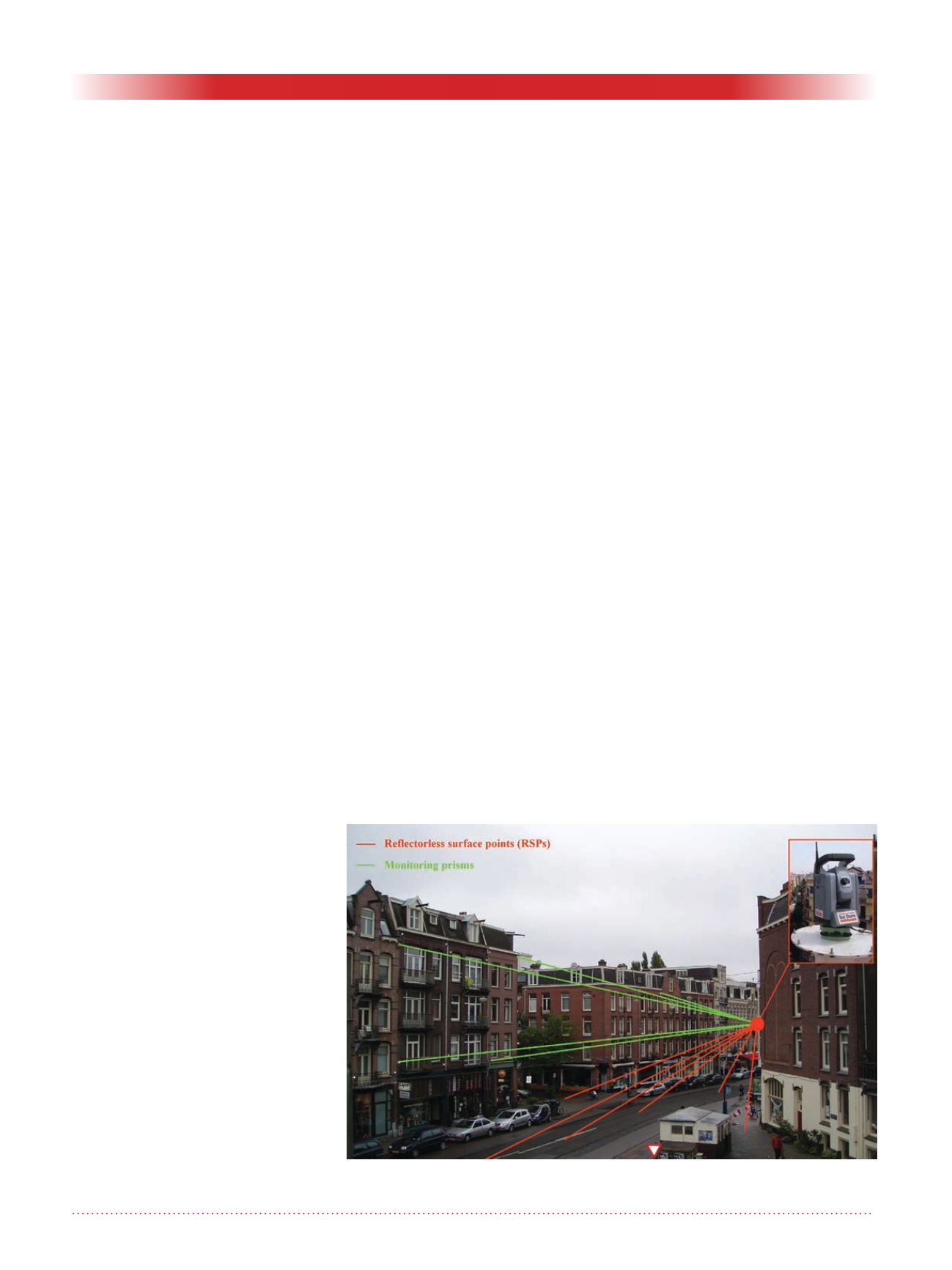

Principle of operation

A remote monitoring system able to

measure surface deformation 24 hours

a day is made up of:

• A robotic total station (RTS)

equipped with a reflectorless dis-

tance meter.

• A support platform, electronics

box, and 3G or Wi-Fi system.

• A data logger which can be oper-

ated remotely with specific soft-

ware able to drive

the total station

to the predetermined locations of

the monitored points.

• Computation software, which can

be more or less advanced, for

calculating the movements of the

points of interest.

During each monitoring cycle the

instrument sights at (see Figure 1):

• The reflectorless surface points

(RSPs) on a flat, homogeneous and

planar surface for which vertical

deformation is to be monitored.

RSPs are not physically marked

and are not physical objects; they

are just a location on the ground at

which the RTS is sighting.

• The stable reference prisms, which

permit computation of the correct

position and orientation of the

RTS.

• If necessary, the same total station

and software can sight monitoring

prisms installed on structures to be

monitored in 3D, as for a standard

RTS.

On completion of the cycle, the raw

and/or calculated data are sent to the

database via Wi-Fi or 3G. The system

can also trigger alarms sent by SMS or

e-mail if predetermined thresholds are

exceeded.

Main fields of application

Monitoring of road surfaces during

underground work.

Accuracy

The accuracy of the RRTS method has

been confirmed by comparing precise

levelling with RSP movements. Exter-

nal controls confirmed a consistency

better than ±1 mm.

Main advantages

• High frequency of readings pos-

sible (down to one reading per

hour for example)

• Uninterrupted traffic, neither for

installation nor for taking readings

• Very safe, no surveyors on the road

• Very cost effective for high fre-

quency of readings

Main limitations

The range of the distance meter

is limited, and so is the angle of

incidence of the laser beam on the

measured surface. Weather conditions

also downgrade the emitted distance

meter signal.

Case histories

The RRTS method has been well

proven in practice in many work sites

since 2005.

• In Amsterdam (Netherlands) over

82 RTS

are used to measure more

than 5000 RSPs above the tunnel

boring machine during the con-

struction of the metro line.

• In Toulon (France) a network of

1830 RSPs has been measured

over roads and pavements from 36

RTSs during four years.

• In Barcelona (Spain) long-term

monitoring of the high speed

railways tunnel and of Metro Line

9 has been set up to monitor settle-

ment on roads, sometimes with

heavy traffic.

Damien Tamagnan

SolData Group, Head of survey

department, Travesia Industrial,

149 -3ª C 08907 Hospitalet de

Llobregat Barcelona (Spain).

T: +(34) 93 263 29 69.

E:

Figure 1. A Reflectorless Robotic Total Station (RRTS) measuring RSPs and

prisms.