36

Geotechnical News • March 2012

WASTE GEOTECHNICS

Challenges with meeting regulatory compliance

in the oil sands industry

Nicholas Beier, Amarebh Sorta, Ward Wilson, David Sego

Introduction

Mining and extraction of oil sands

to produce bitumen has been under-

way in north eastern Alberta for over

five decades. The Canadian oil sands

deposit is home to an estimated 300

billion barrels of recoverable bitumen.

At current and predicted production

rates, oil sands exploitation will con-

tinue long into this century. A typical

oil sand ore deposit is comprised of

bitumen (~12 wt%), sand, silts, clays

(mineral content ~85 wt%) and water

(3-6 wt%). The mineralogy of the clay

component is typically kaolinite (50-

60%) and illite (30-50%) with some

montmorillonite (Beier and Sego,

2007).

The production of bitumen from the

oil sands ore body is based on open

pit mining and a hot water extraction

process. Warm to hot water, steam and

process aids such as caustic (NaOH)

are used to extract the bitumen from

the mineral matrix. The extraction pro-

cess recovers 90-92% of the bitumen

and produces a tailings stream consist-

ing of water sand silt clay and residual

bitumen. Typically, the tailings streams

are discharged at approximately 55

wt% (82 wt% sand and 17 wt% fines

defined as <44 µm) into tailings ponds

to recover water. The coarse fraction of

the tailings slurry is used to construct

perimeter dykes using cell construc-

tion or beach discharge. Some fines are

trapped within the sand matrix of the

beaches during this process (≥50%),

while the remaining fines and water (8

wt% fines) flow into the settling pond

(referred to as thin fine tailings). The

fines slowly settle over a few years

to 30-35 wt% and are referred to as

mature fine tailings (MFT). Further

consolidation of the MFT is extremely

slow (in the order of centuries). The

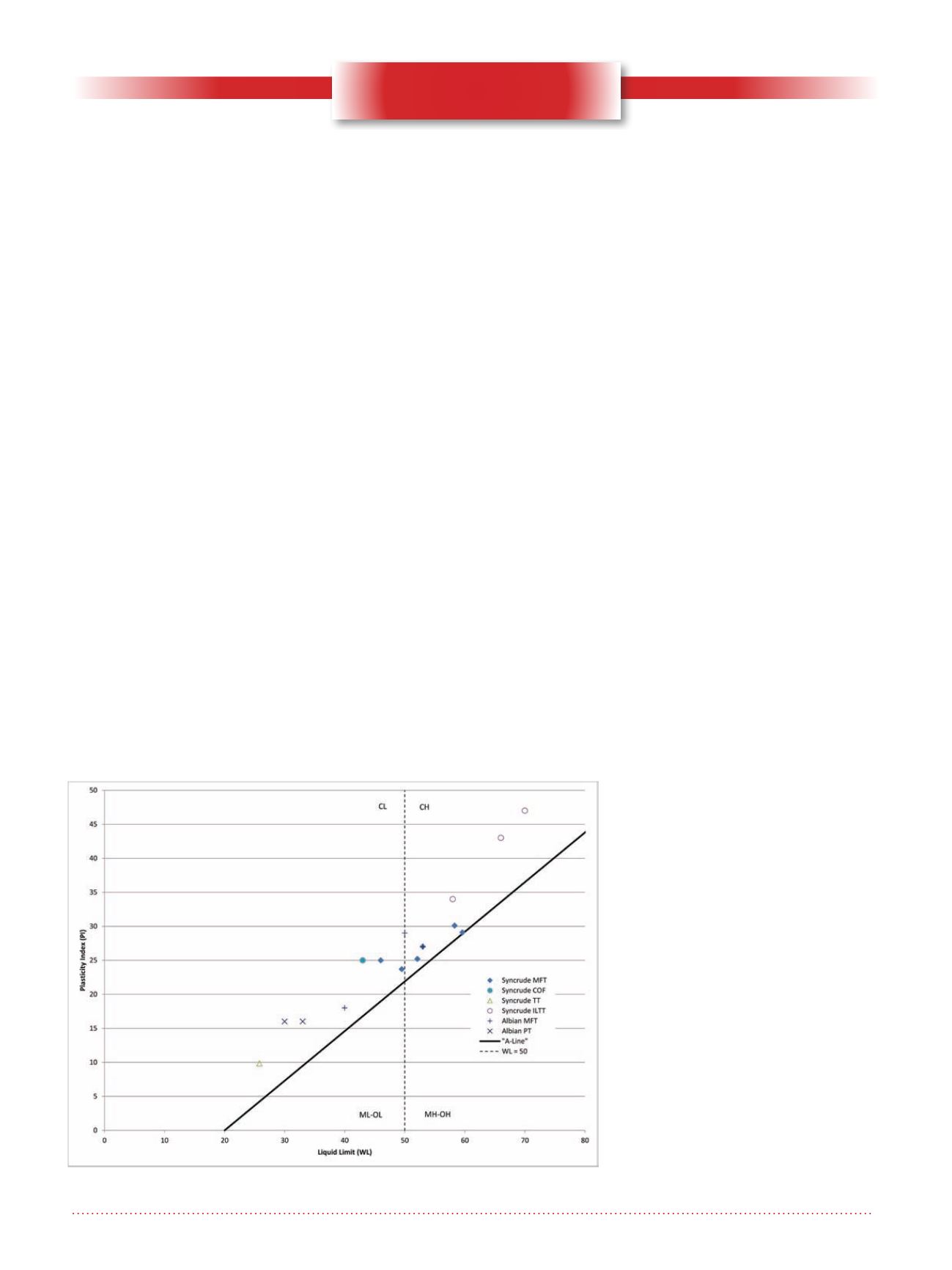

typical Atterberg limits for a range of

MFT are shown in Figure 1. On aver-

age, approximately 1 m

3

of sand and

0.25 m

3

of MFT have been created for

every barrel of bitumen that has been

produced thus far (Beier and Sego,

2008). This has led to the accumulation

of 800 billion m

3

of MFT (Hyndman

and Sobkowicz, 2010) which requires

long-term storage in fluid containment

structures.

The oil sands industry has developed

methods to deal with this inventory

of MFT. For example, the process of

mixing sand with the MFT, termed

consolidated or composite tailings

(CT), requires a mixture of segregated

sand (from a cyclone underflow), MFT

and a coagulant (gypsum). The CT is

mixed at sand to fines ratios (SFR) of

approximately 4:1 and is not expected

to segregate during transport, discharge

or deposition. However, operational

challenges have hindered the com-

mercial full scale success of CT. The

CT operation must compete for sand

that is also used to provide economi-

cal containment dykes. Additionally,

inconsistent control on the CT slurry

densities and/or the depositional tech-

nique (shear environment) has lead to

segregation of the CT slurries resulting

Figure 1. Plasticity chart of oil sand fine tailings.