38

Geotechnical News • March 2012

WASTE GEOTECHNICS

(in-pit lake) or dewatered separately

creating a cohesive, silty clay deposit.

The industry is trending toward

managing the fine stream with various

chemical, physical and environmental

dewatering techniques. In short, the

objective is to dewater the fines stream

sufficiently to meet the Directive 074

performance criteria.

In addition to Directive 074 require-

ments, the chosen tailings manage-

ment process should satisfy both

operational and reclamation/closure

goals (Hyndman and Sobkowicz,

2010). As the mining operations

proceed, tailings should be reclaimed

progressively, thereby limiting the

accumulation of fluid fine tailings that

would require containment, leaving

remediation to the end of mine life.

Fluid containment structures should be

limited to a minimum (i.e., only what

is required for effective tailings man-

agement). Meeting these operational

goals would allow the operator to pro-

ceed with reclamation and return the

mine site back to the public, thereby

achieving the reclamation goals.

Essentially, operators would be able

to avoid tailings ponds/dams in the

closure landscape that would require

ongoing maintenance (in the order

of decades); transform the tailings

deposits into geotechnically stable

landforms that are resistant to natural

processes and are self-sustaining both

physically and environmentally; and

ensure these landforms and features

are integrated into the future natural

ecosystem successfully.

Physical/mechanical dewatering

methods include centrifugation and

high rate thickeners (thickened tailings

[TT]) or paste thickeners (paste thick-

ener [PT]). In centrifugation opera-

tions, MFT is dredged from a tailings

pond, diluted and then mixed with a

polyacrylamide flocculant. The floccu-

lated fines stream is then processed in

the centrifuge and dewatered to nearly

55 wt% (water content [WC] of 80%)

prior to deposition. The fines stream

for thickeners would come directly

from the extraction process rather than

from the MFT pond. Sand-depleted

tailings streams or cyclone overflow

(COF) would be flocculated and

dewatered in the thickeners prior to

deposition at solids contents reaching

60 wt% (WC of 67%). Alternatively,

the fines may be dewatered through

a combination of chemical addition

and strategic deposition. Polymer

solutions are injected directly into the

transfer pipeline containing dredged

MFT or COF (dilution is optional).

This process is termed “in-line floc-

culation” or in-line thickened tailings

(ILTT). Two depositional techniques

are available for the flocculated fine

material. The mixture (well above the

liquid limit) can be discharged onto

a gently sloped beach in thin layers

where initial dewatering occurs due

to shear, settlement and drainage from

the flocs, followed by environmental

dewatering (desiccation, freeze/thaw).

The flocculated tailings may also be

discharged into large depositional cells

(>10 m deep) to promote self-weight

consolidation and environmental

dewatering via the surface. As water

is released to the surface, active water

management is required via decant

structures and mechanical channel-

ing (perimeter ditching) to promote

further dewatering and development of

strength. This later depositional tech-

nique is referred to as rim-ditching or

accelerated dewatering. Each of these

fines management techniques involves

some form of polymer or chemical

addition to promote dewatering and

strength gain. However, it is important

to note that the dewatered fines are

being placed at water contents above

their natural liquid limit (LL).

Implications of fines

management techniques

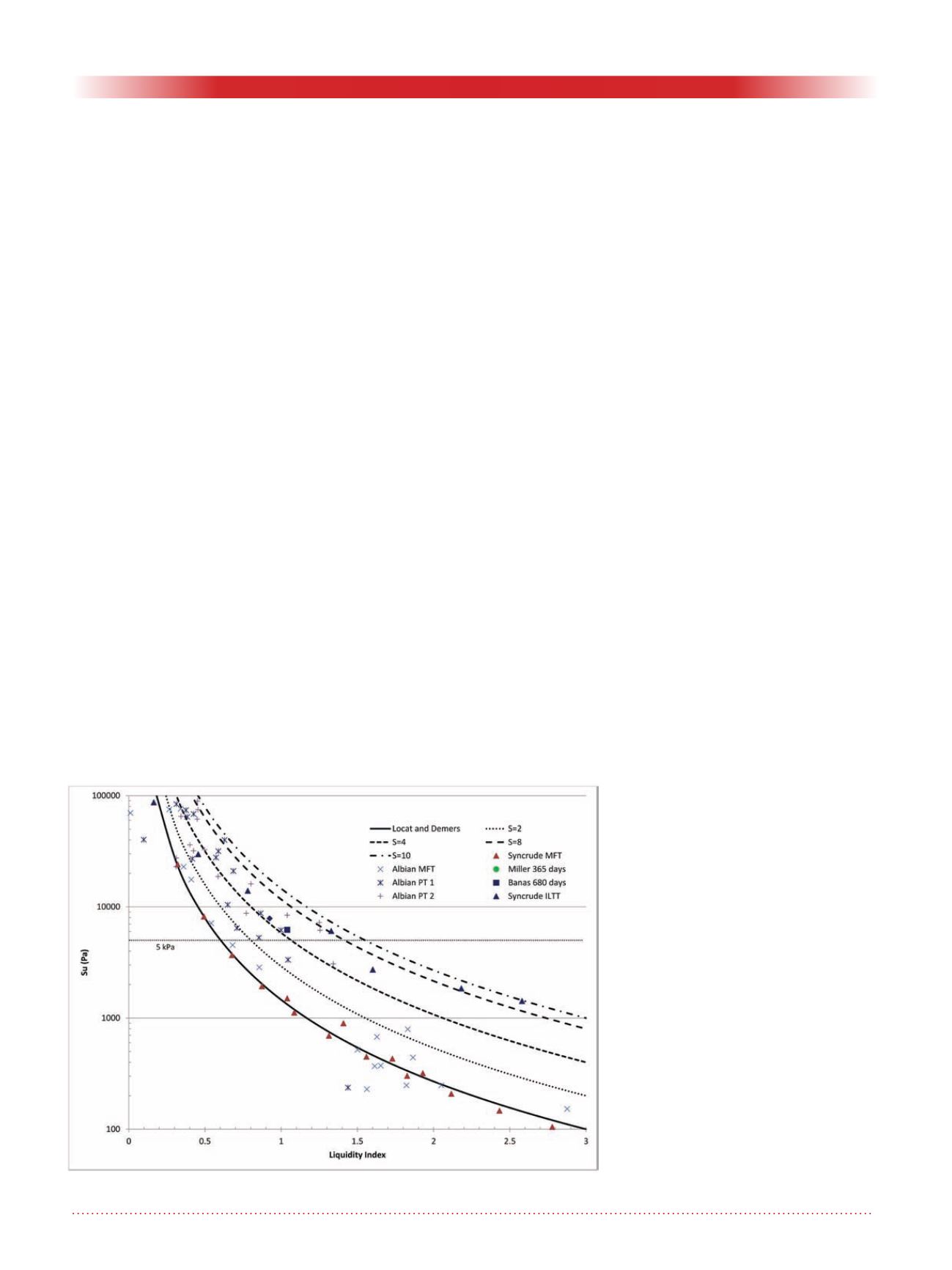

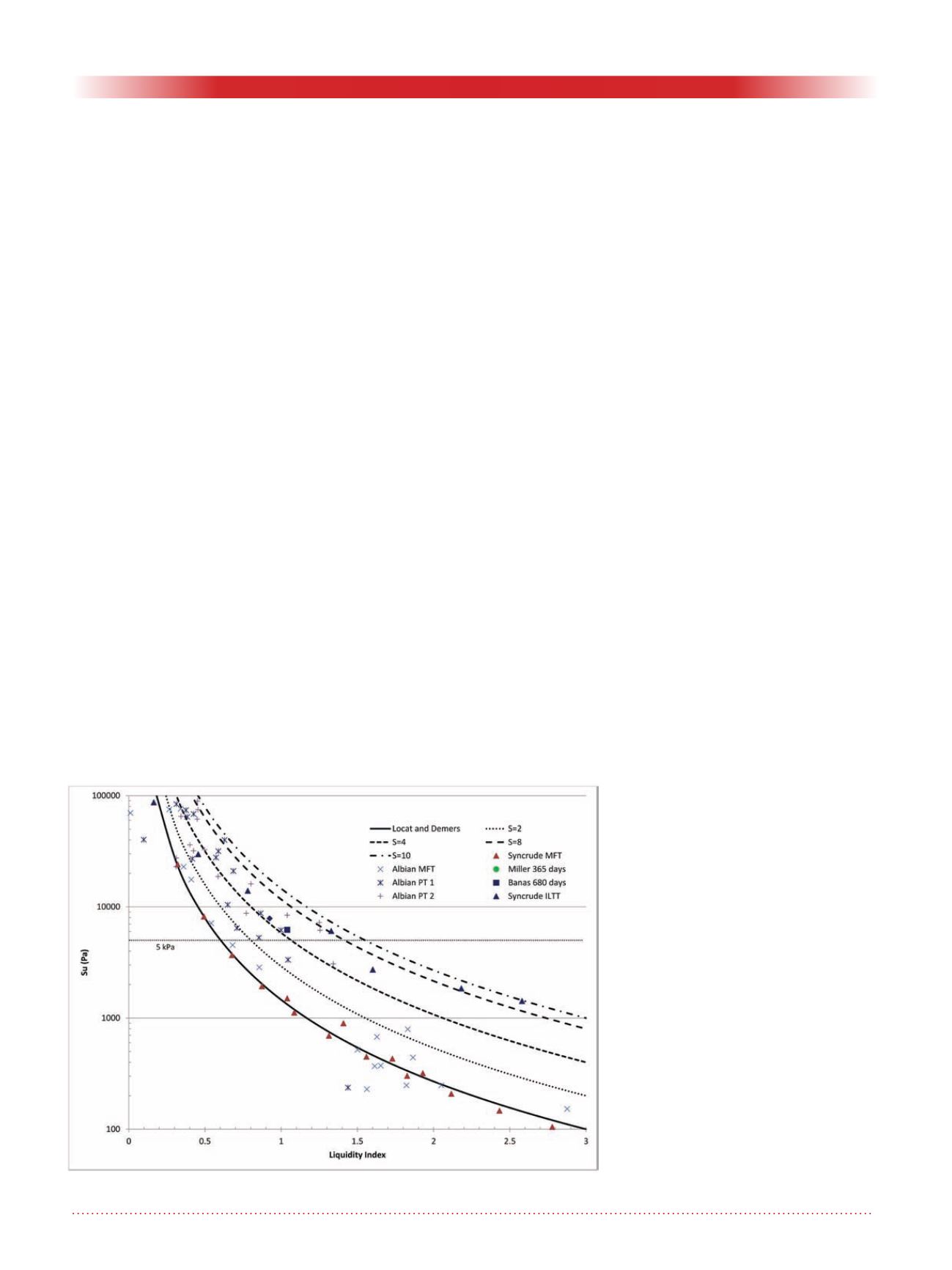

The performance measure for fine-

grained deposits in Directive 074

requires an undrained shear strength

(Su) of 5 kPa one year after deposi-

tion. For typical MFT, this would

require dewatering from water

contents of 233% to below their LL

(a Liquidity Index [LI] of 0.6). Figure

2 depicts this relationship between

LI and remolded Su for typical MFT

from the Albian Sands and Syncrude

mining operations. Additionally,

Figure 2 contains data for natural

clay deposits as reported in Locat and

Demers (1988) and Mitchell and Soga

(2005). As can be seen, the relation-

ship (Equation 1) proposed by Locat

and Demers (1988) provides a good

overall fit for typical MFT.

Equation 1.

Su

remolded

= (19.8/LI)

2.44

Figure 4. Sensitivity of oil sands fine tailings.