Geotechnical News • March 2012

37

WASTE GEOTECHNICS

in the release of low SFR materials that

are difficult to reclaim (Hyndman and

Sobkowicz, 2010). Since the 1980s,

technical advances have been made

in mining and material handling and

bitumen extraction. However, finding

practical methods to control and reduce

the fluid fine tailings formation build

up has been an ongoing challenge.

Oil sands tailings regulations

The Energy Resource Conservation

Board (ERCB), Canada’s regulatory

body responsible for the oil sands

industry, has been concerned regarding

past tailings management practices,

continual accumulation of fine tailings

and the associated risks to reclama-

tion activities. As such, they elected

to regulate fluid fine tailings through

performance criterion, and in early

2009 the ERCB issued Directive 074:

Tailings Performance Criteria and

Requirements for Oil Sands Mining

Schemes. The aim of the directive is

to reduce fluid tailings accumulation

by capturing the fines in dedicated

disposal areas (DDAs) and create

trafficable surfaces for progressive

reclamation. The Directive requires

operators to submit tailings plans, tail-

ings pond status reports, disposal area

plans and compliance reports. Compli-

ance with Directive 074 can be directly

measured through specified strength

performance in the tailings deposits.

The Directive requires a minimum

undrained shear strength of 5 kPa

for tailings material deposited in the

previous year. If any material fails to

meet the 5 kPa requirement, it must be

removed or remediated. Additionally,

five years after active deposition, the

deposit must be trafficable and ready

for reclamation. The metric for “traf-

ficable” after five years requires the

deposit to have a minimum undrained

shear strength of 10 kPa. It is evident

new technologies and processes must

be developed to supplement current

tailings management plans, specifi-

cally, additional fines-management

techniques. Specification of a short-

term strength requirement may sound

like a positive exploit – at least at

first glance. However, the regulation

may inadvertently misdirect indus-

try efforts. The following discussion

attempts to explain some of the issues

and challenges.

Fine tailings management

Implementation of the ERCB’s Direc-

tive 074 has driven industry to review

current tailings management tech-

niques and investigate the numerous

alternative technologies and processes

to manage and reclaim fine tailings.

Essentially, there are three general

methods to incorporate the problem-

atic, clay dominant fine tailings into

a closure landscape. The fines can be

sequestered into the coarse tailings

matrix (CT), placed under a water cap

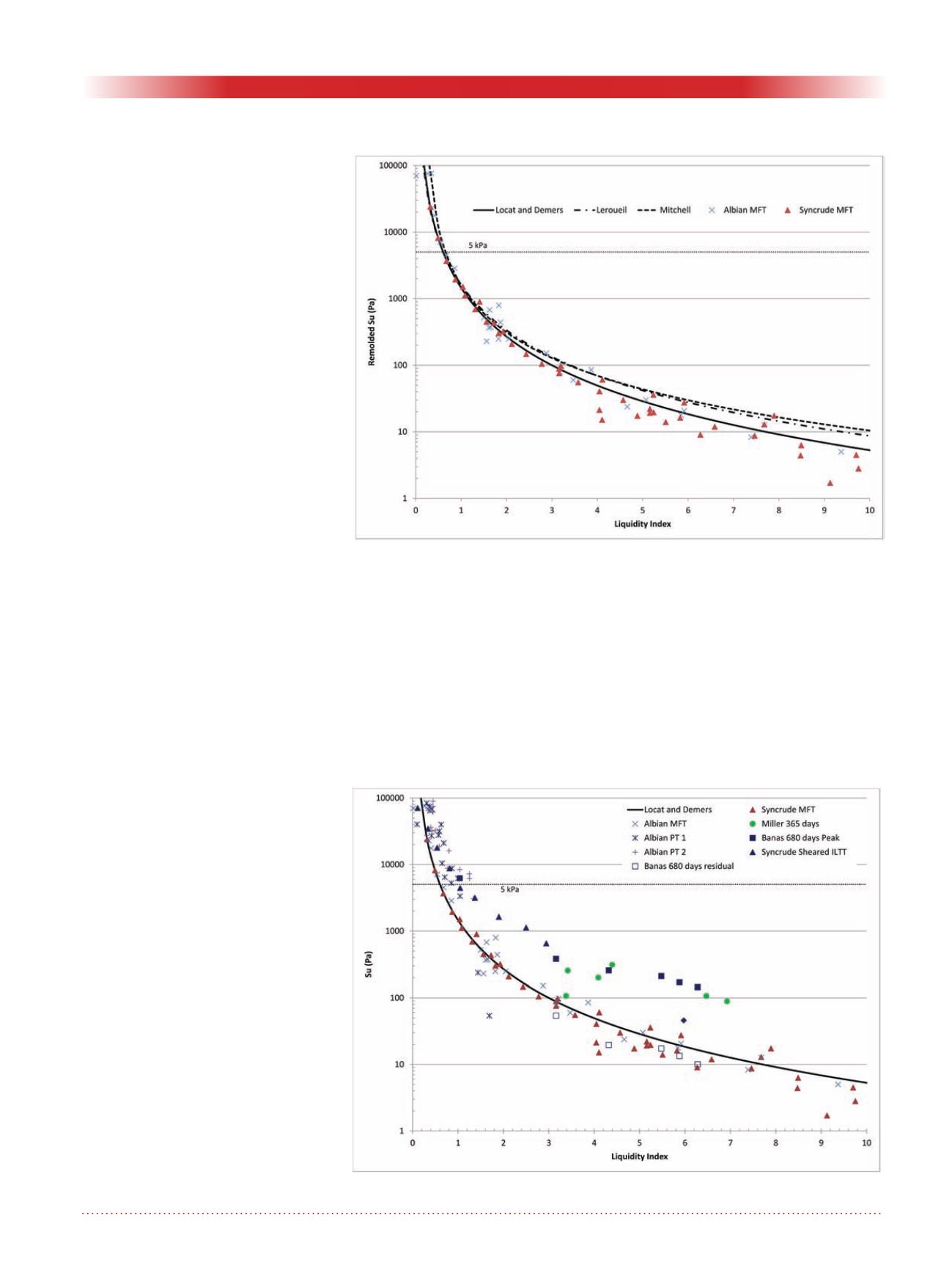

Figure 2. Remolded undrained shear strength of oil sand MFT.

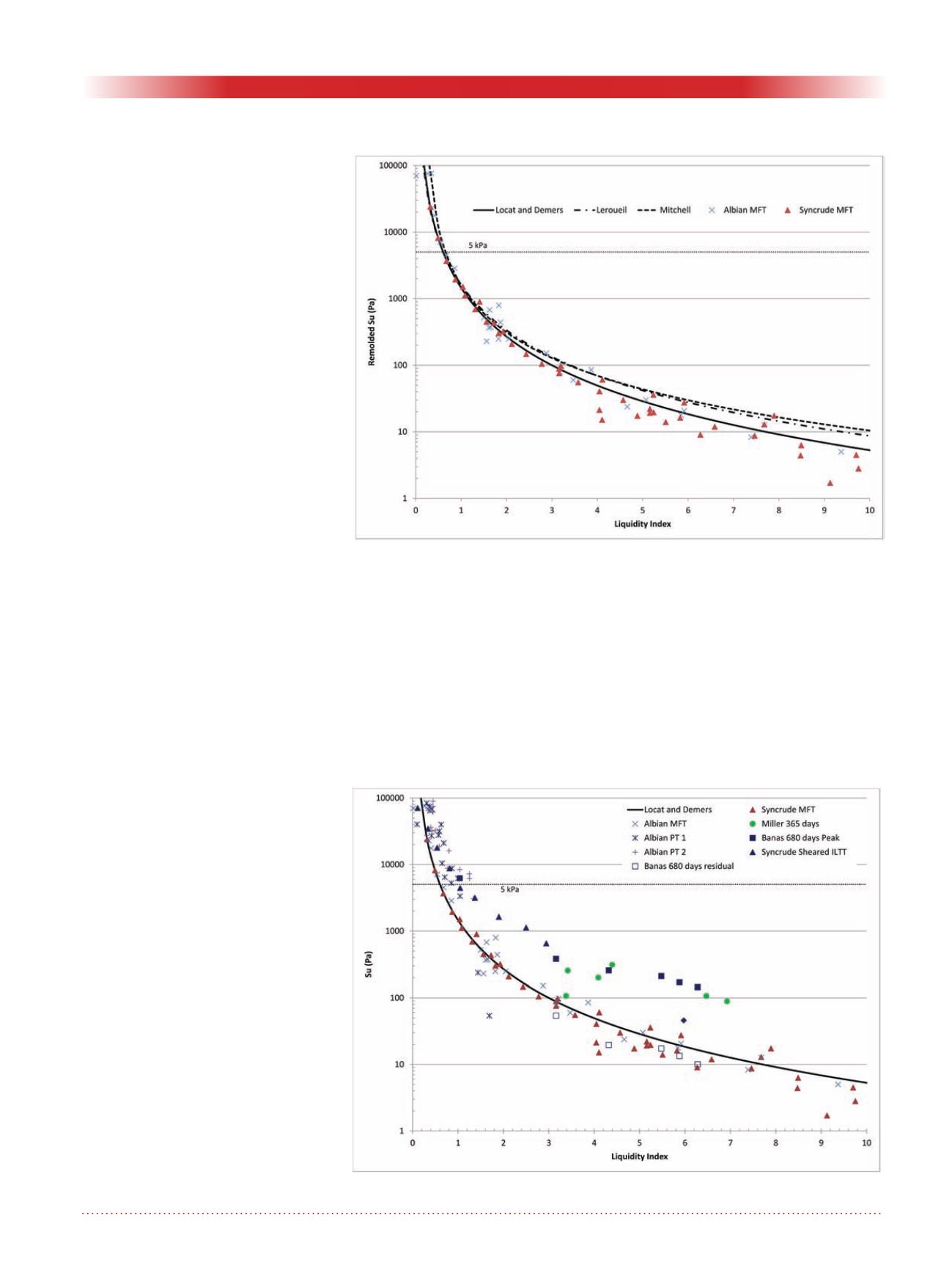

Figure 3. Undrained shear strength of oil sands fine tailings.