34

Geotechnical News • March 2012

GROUNDWATER

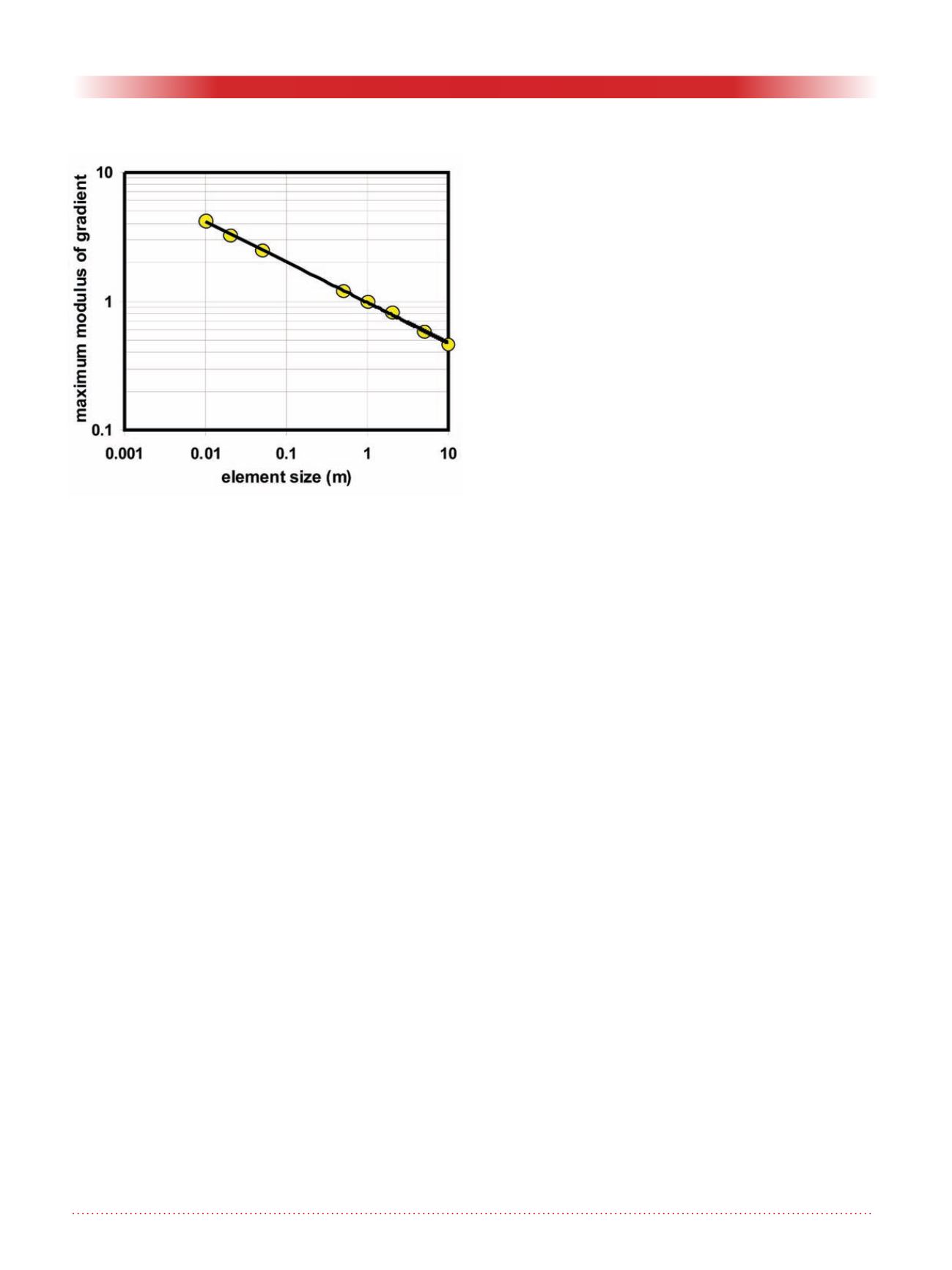

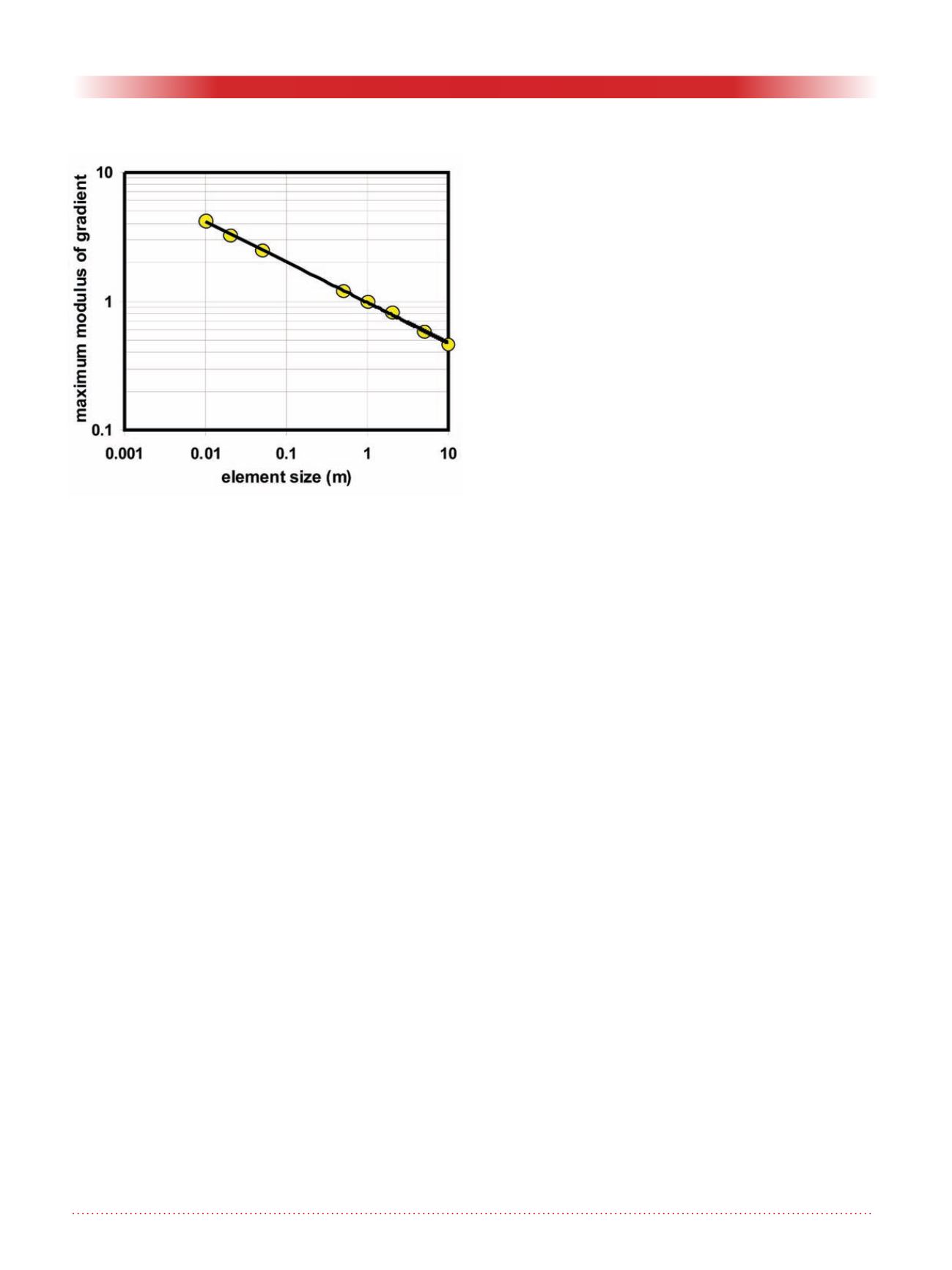

(Figure 5) but the relative error is still

about 7% for elements of 1 m. The

error drops to about 1% for elements

of 20 cm and about 0.1% for elements

of 5 cm. Similarly, the numerical value

for

h

(

r

= 20.15 m) converges towards

the closed-form solution (Figure 6),

but elements of 10 cm or less are

needed for a good accuracy.

For this example, note that the 2003

version of the code has a marked

advantage over the 2007 version,

because it can use a progressive

(logarithmic) meshing, which has

been removed in the 2007 version

that uses a different meshing process.

The logarithmic meshing provides

a much better accuracy for a much

smaller number of elements (Figure

7), which reduces the calculation time,

especially for transient problems. It

enables the use of very small elements

close to the screen, where the gradient

reaches its maximum, and large ele-

ments at the distant boundary, the size

of elements increasing gradually as the

radial distance increases.

General rules for meshing

As for large-scale groundwater stud-

ies, a few basic principles should

be observed for adequately treating

small-scale

details in numeri-

cal studies. First,

we must have

a preliminary

idea of how the

hydraulic head

varies within

the volume of

our study. For a

first appraisal we

can use a coarse

mesh, which

will give us a

first solution. We

must examine

this first solution

and identify the

zones with large

local variations

in hydraulic

head

h

, and (for

unsaturated zones) in water pressure

u

. These zones are those where our

mesh must be refined. For a second

appraisal, we can keep the large initial

mesh for the volumes where the

h

variations are small, and generate

finer meshes in the volumes of high

h

variations (high gradient zones).

When examining the second solution

and the zones of high variations, we

may find that some local refinements

are still needed. Once we are satisfied

with our last refinement and believe

that further refinement would add

nothing, we should not be satisfied

with our belief, but must prove it. We

must prepare a confirmation mesh in

which all elements will be smaller (by

half, for example) of what we thought

would be our last mesh. The confir-

mation mesh should give the same

results (heads, gradients, velocities,

flow rates, etc.) as our last mesh. If so,

then we have the proof that we have

designed and retained a correct mesh.

Note that the computing time for the

verification mesh may be about four

to nine times longer than the time for

our final and correct mesh. Thus, we

should avoid using the verification

mesh for long transient problems (the

computing time for this verification

could take many hours or even days)

but use it first for faster-to-solve

steady-state problems (which could

then also serve as initial conditions for

the longer transient simulations).

Two simple rules to observe are:

(i) The higher the local variations in

h

(anywhere), gradient (anywhere)

and u

w

(unsaturated zones), the fin-

er the local mesh;

(ii) The final solution must be

independent of the mesh size.

Conclusion

This short paper has examined two

examples, a partial cut-off wall for a

dam, and a steady state pumping test

of a confined aquifer. For the two

examples, the code used here reached

immediate numerical convergence

in two steps, the relative error on the

modulus of the pore pressure vector

being less than 10

-6

. This rapid con-

vergence is mostly due to the linear-

ity of equations for fully saturated

seepage and steady state. However,

different numerical solutions were

obtained for different grid sizes. In

short, we observed that the finer the

grid, the more accurate the numerical

solution. It is also important to model

all geometric details as accurately as

possible. In areas where the gradient

reaches a local maximum or mini-

mum, the use of progressive or loga-

rithmic meshing was shown to provide

a clear advantage in terms of accuracy

and calculation time.

To complement this paper which

focuses on small scale details with

high local variations of the hydraulic

head and gradient, and the previ-

ous paper on large-scale studies, a

forthcoming paper will provide a few

examples for cases in which unsatu-

rated seepage plays a key role.

References

Chapuis, R.P. 2009. Relating hydraulic

gradient, quicksand, bottom heave,

and internal erosion of fine par-

ticles. Geotechnical News, 27(4):

36–38.

Figure 4. Partial cut-off wall: Divergence of the local max-

imum gradient at the upstream of the cut-off wall toe.