Geotechnical News • December 2015

43

THE GROUT LINE

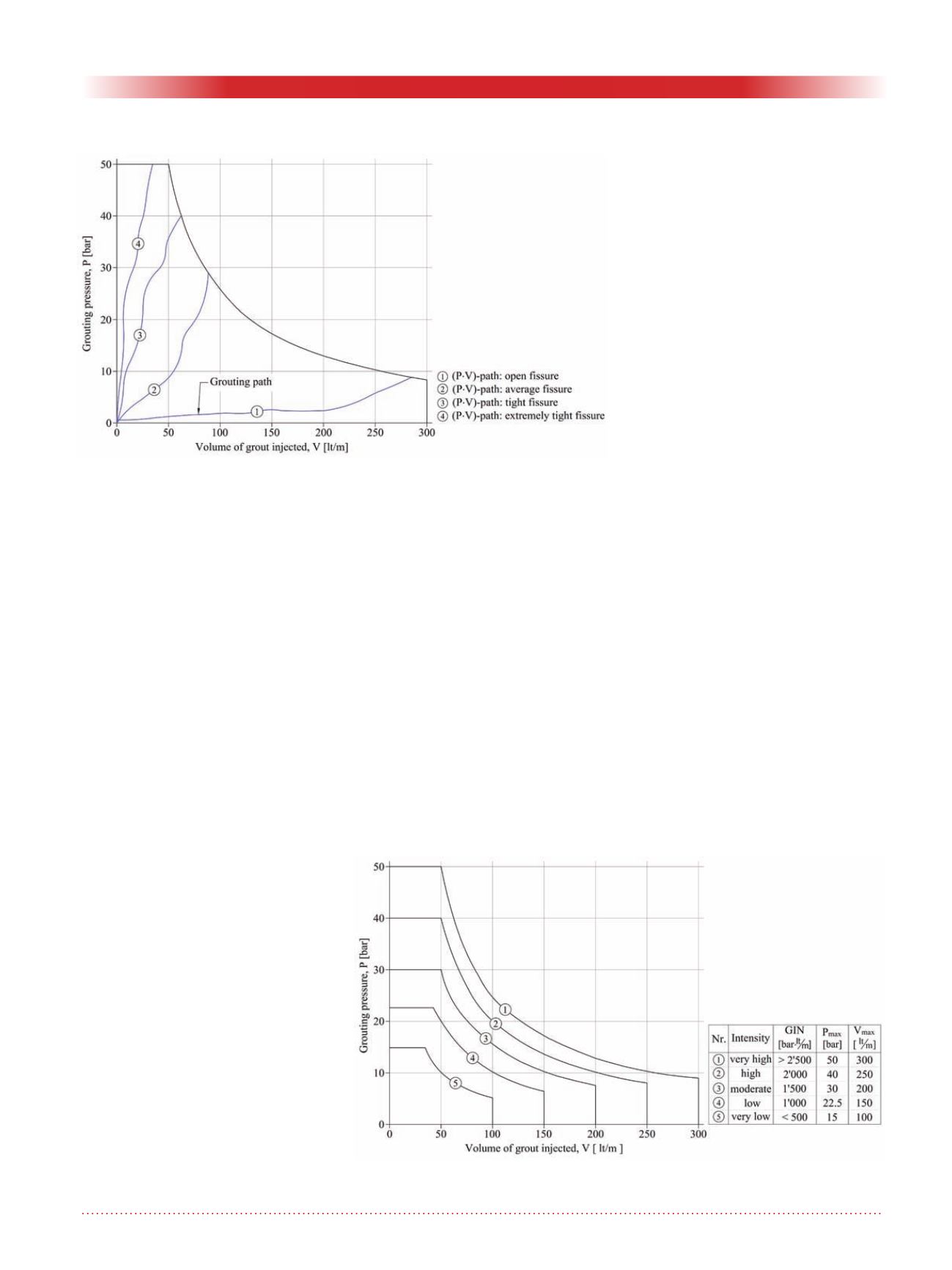

damage due to too higher pressures,

as is sometimes erroneously done,

becomes therefore superfluous. Fol-

lowing the GIN concept, the grout

takes near the surface or gallery, where

the fissures generally tend to be rather

open, automatically increase, while the

pressure remains rather low. At depth,

on the other hand, the openings are

generally smaller so that less grout is

absorbed. As shown in Figure 2, the

grout path in this latter cases (grout

paths 3 & 4) is steep reaching quickly

higher pressures. Therefore, respecting

this self-adaptive nature of GIN grout-

ing, once a certain maximum pressure

is defined, it should be kept constant.

Changing systematically the maxi-

mum pressure in function of depth

does not only unnecessarily compli-

cate the whole grouting procedure,

but it also carries the risk of stopping

grouting before the natural equilib-

rium is actually reached, resulting in

an incomplete execution of the works.

The only zone where a certain pres-

sure limitation might be acceptable is

the upper 5 m, in order to avoid grout

break-out to the surface, especially if

grouting is not performed through a

concrete slab or similar. To ensure an

efficient grout result along the entire

borehole length, it is common practice

to increase in addition

In this respect, it is recalled that the

adequacy of the selected maximum

grouting pressure can be best con-

firmed by several representative grout-

ing test sections.

Maximum grout take (target

volume)

The maximum grout take does actu-

ally not present an absolute stop crite-

rion. It rather defines a decision point

on whether to

à

à

Continue grouting

à

à

Terminate grouting

à

à

Pause grouting and restart later

after setting of grout

à

à

Abandon the hole & drill an-

other one nearby

à

à

Modify the grout mix

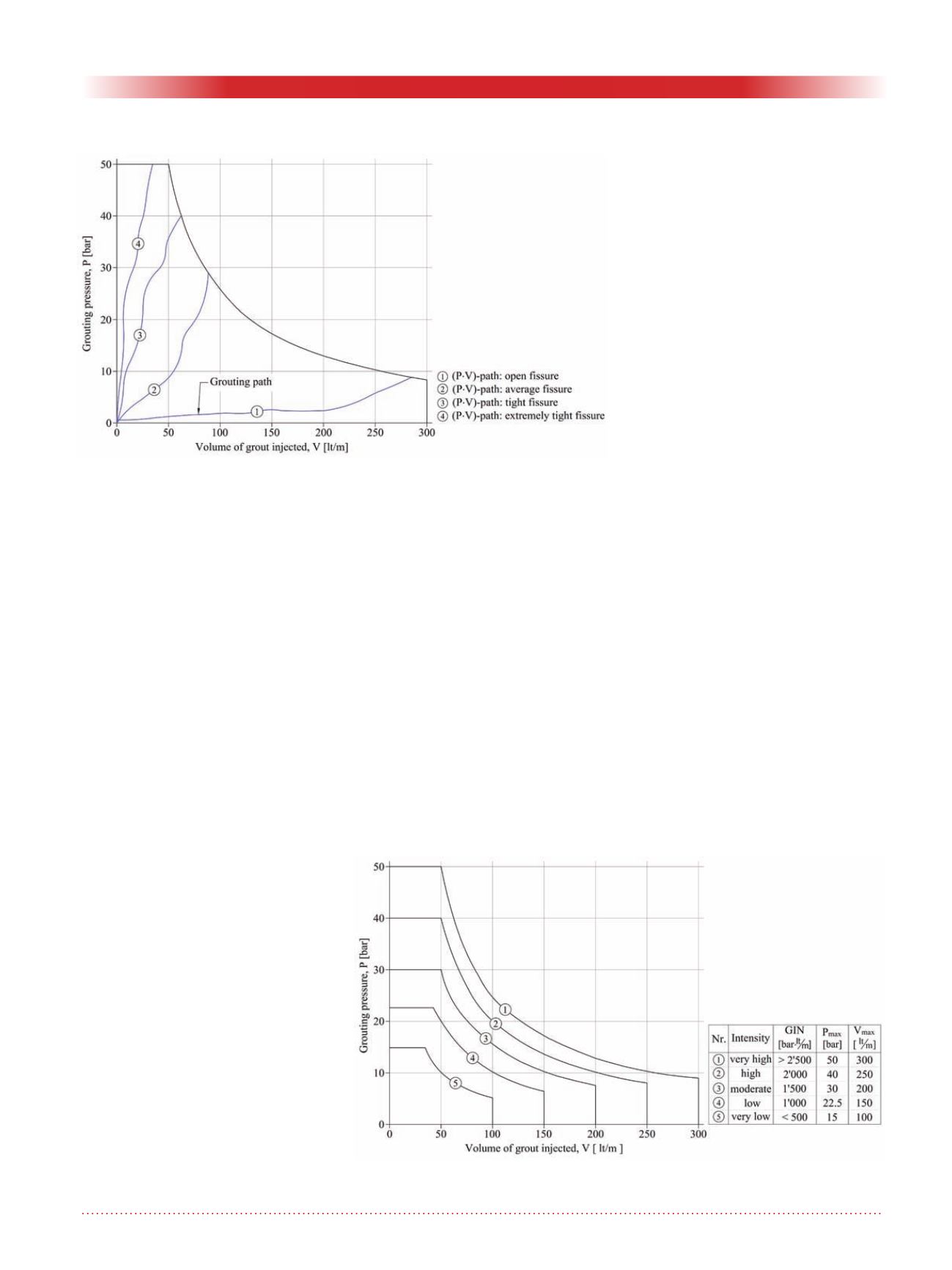

In contrast to the grouting intensity

number and the maximum pressure,

this parameter is mainly defined

considering economical rather than

physical aspects. A rough indication

of commonly chosen maximum grout

takes, V

max

, for certain grouting inten-

sities is given in Figure 3.

Mix design

One of the key aspects of the GIN

concept is the use of a single stable

grout mix. The mix should be for-

mulated to achieve the specified

performance criteria as efficiently as

possible (i.e. the minimum number

of boreholes, the minimum number

of injection phases, and the optimum

injection rate throughout each individ-

ual injection). Its selection and design

is based upon a thorough understand-

ing of the site rock conditions, includ-

ing fissure widths. It stands to reason

that one of the most important aspects

actually limiting the groutability is

the maximum cement grain size rela-

tive to the fissure width. As a general

rule, for a fissure to be groutable, its

aperture should be at least three times

the maximum grain size of the cement.

Finally, the mix is also of low water-

cement ratio to ensure both long-term

strength and durability, and the avoid-

Figure 2. Grouting paths for different fissure openings, illustrating the self-

adaptive nature of GIN grouting.

Figure 3. Typical range of GIN values, as well as corresponding maximum

pressures and volumes.