46

Geotechnical News • December 2015

THE GROUT LINE

Provided that the limiting grout pres-

sures are not exceeded, the aim should

be to pump as quickly as practicable.

The GIN technique ensures that the

limiting pressure is progressively

reduced as the total injected volume

increases, and this limit is defined and

enforced by the GIN boundary curve.

It is prudent to limit the injection

rate over the first 15-50 L to avoid

immediately reaching the maximum

limit pressure, and modern control

measures allow for an injection rate

of, for example, 300 L per hour until

this volume has been placed. There-

after, the pump can be programmed

to seamlessly and automatically

increase injection rate up to its practi-

cal maximum, typically in the range

1’000-1’200 L per hour. This injection

rate should ideally be constant for all

injections, and each injection will con-

tinue at this rate until the plot of the

GIN value P x V approaches to within

approximately 1 bar below the GIN

boundary curve.

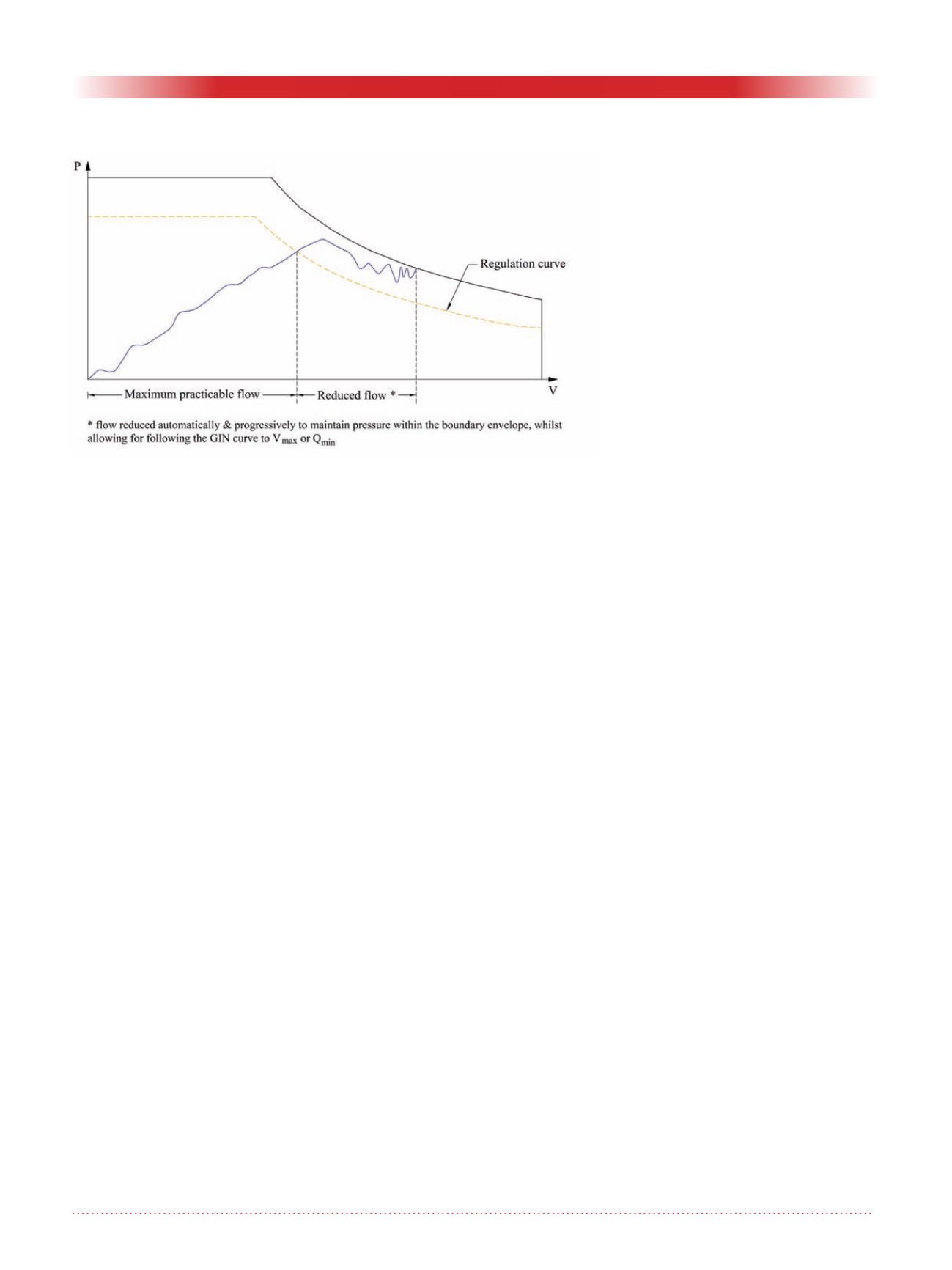

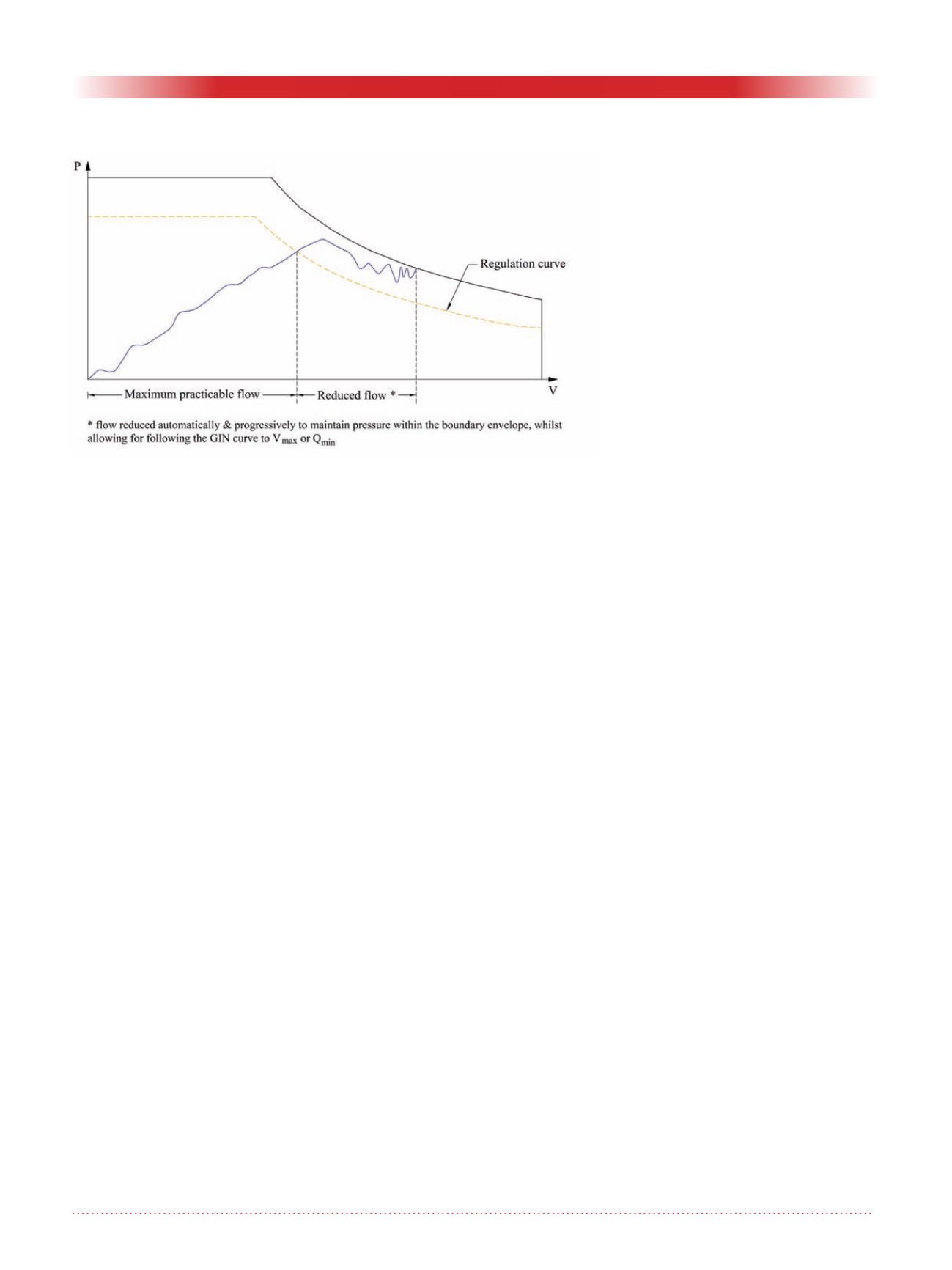

Practical experience has shown that

it is convenient to define a certain

regulation zone, when approaching

the GIN curve, for which a reduced

flow rate is imposed. As shown in

Figure 5, this zone is bounded by the

GIN curve itself and by a parallel

regulation curve typically at around

1-2 bars below the GIN value. Within

the regulation zone the pump flow

rate varies automatically according to

the cumulative grout volume and the

rock conditions, to maintain the GIN

plot within the regulation zone until

the injection terminates on minimum

flow or maximum volume. The path

of the GIN plot and the point at which

the GIN plot intersects the boundary

curve will be dependent upon the mix,

the pump injection rate, and the rock

characteristics. Once the cumulative

volume injected reaches the target vol-

ume for the stage, or the pump reaches

its minimum practicable and/or

economic pumping rate, the injection

terminates automatically. The target

volume and the minimum flow rate are

all pre-set into the software and cannot

be accidentally exceeded.

Once automatic regulation com-

mences, limiting the injection rate,

for low grout quantities, for too long

a time in this regulation zone, would

make the grouting works unneces-

sarily complicated and uneconomic.

There are mainly two options for the

termination criteria – either continue

grouting at a reducing flow rate until

the flow rate reduces to a pre-deter-

mined rate (somewhat equivalent to a

classical ‘refusal’ criteria), or the GIN

curve is followed until the previously

defined maximum volume is reached.

Applying the same criteria to every

single injection ensures that the

graphical plot for each injection can

be compared with that of every other

injection, and can provide a great deal

of information about progress and suc-

cess of the individual injection and the

progress of the works. It also, together

with the constant GIN value and mix

characteristics, adds greatly to the sub-

stance and accuracy of any numerical

analyses.

A key element of this visual inspection

is to see on completion of the injec-

tion whether the full target volume

has been injected, or whether the

injection is terminated too early. The

grouting engineer can see at a glance

what percentage of the target volume

has not been placed, and, can make a

judgement as to whether this is due

to improving rock conditions and

reduced transmissivity, or whether

the grout mix is inappropriate for the

formation, and it allows him to see

whether the GIN value is appropriate

or not. If he has any concerns on these

issues then, of course, he must be pre-

pared to modify the parameter accord-

ingly. However, this should ideally

be done for all remaining boreholes.

Varying the injection parameters for

each individual stage renders realistic

and systematic analyses of the results

extremely difficult, and prevents the

application of some very valuable

comparative analyses.

To avoid such an unnecessary com-

plication of the grouting process, it is

advisable, in the early stages of the

project, to immediately drop back

and carry out one or two secondary

injections after the first 3-4 primary

holes have been completed, to verify

that the assumptions made in terms of

target grout volume, GIN value, and

the optimum injection parameters, are

correct. The parameters should then,

if required, be modified at this early

stage and maintained unchanged wher-

ever possible for the remainder of the

works to keep the grouting works as

clear and manageable as possible.

Figure 5. Flow Regulation during the grouting process.