42

Geotechnical News • December 2015

THE GROUT LINE

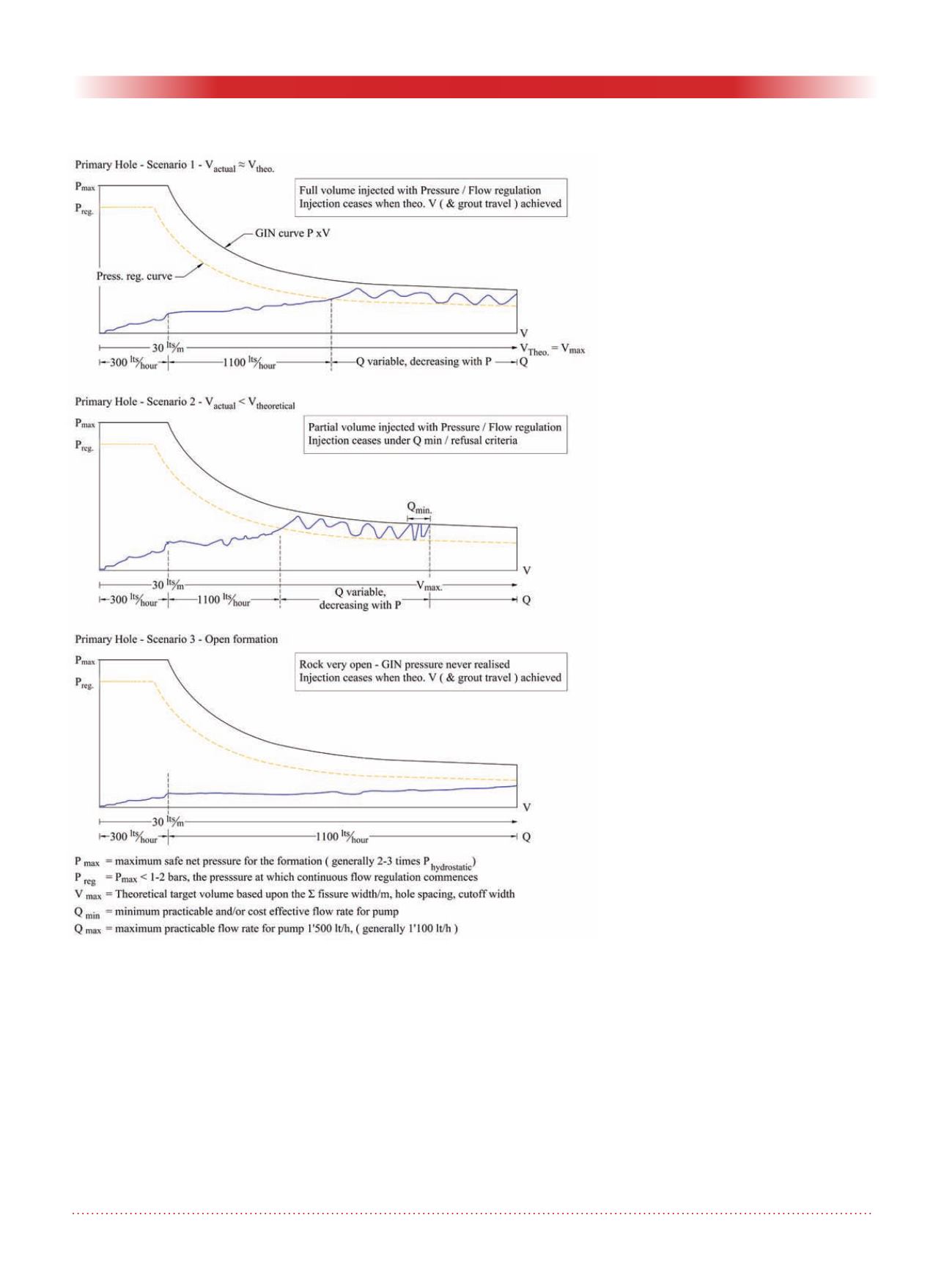

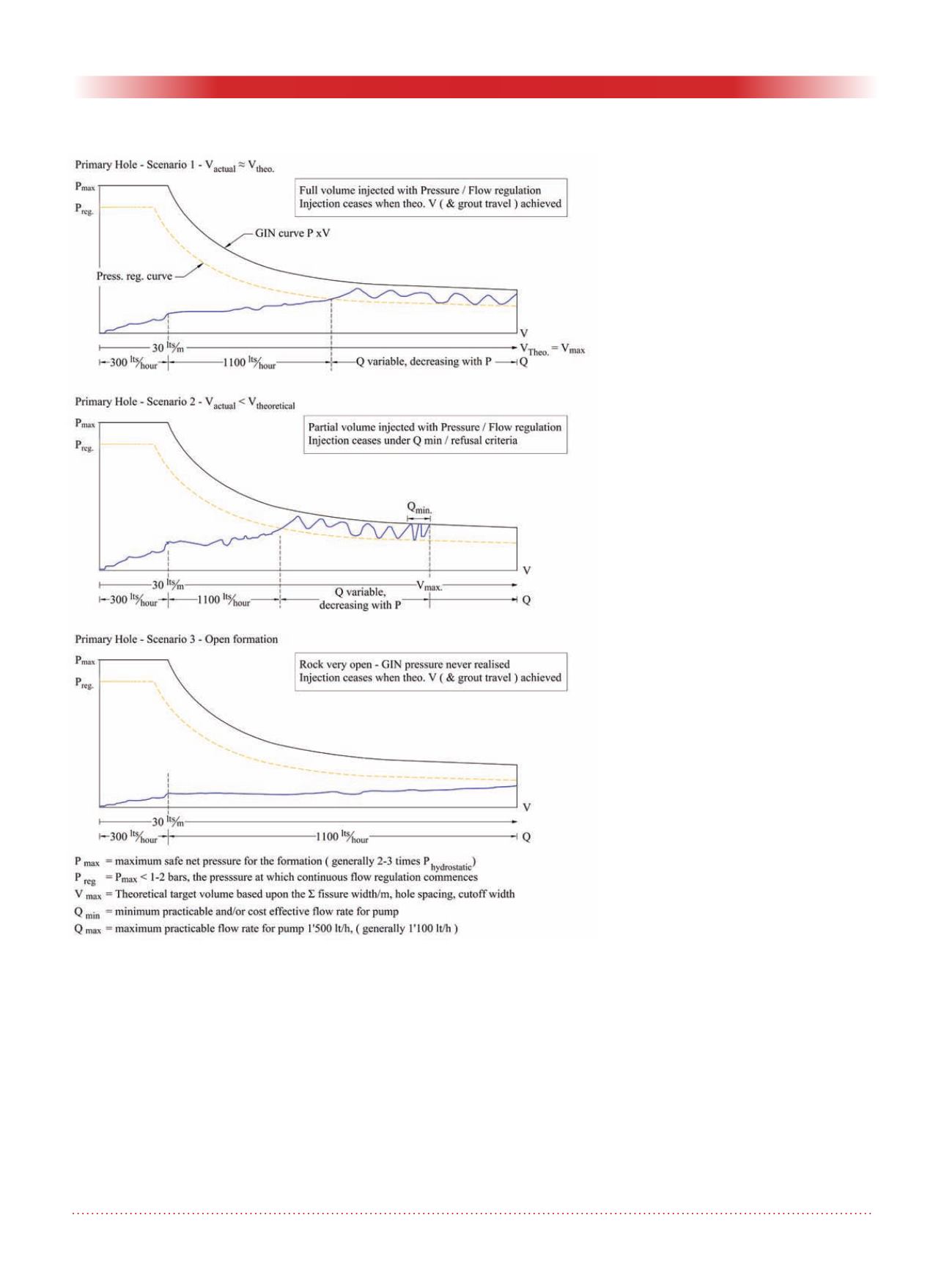

Application of a single GIN value

allows direct comparison of the

graphical and numeric data for indi-

vidual borehole stages, and for the

various phases of injection. It also

allows the grouting engineer to rapidly

assess and gain a feel for the prog-

ress of a single injection and / or the

progress of the grouting programme,

either by observation of the real-time

plot of the GIN curve and the evolving

GIN value during the injection, or by

visual inspection of the graphical plots

on completion of the daily injection

programme. Figure 1 gives typical

examples of the evolution of the GIN

value, within the GIN boundary curve.

Maximum injection pressure

The maximum pressure limit P

max

serves mainly to select the proper

grouting equipment, such as pump,

tubes and valves. Like the GIN itself,

it should be defined so that it complies

both with the rock mass properties and

project requirements.

If the purpose of grouting is, for

example, the impermeabilization of a

dam foundation, the maximum pres-

sure should be chosen according to

the expected future water losses and

uplift pressures after impounding. It

has to be sufficiently high in order

to avoid a fissure opening when the

reservoir is impounded. A common

value for the maximum pressure at the

borehole mouth is around 2 - 3 times

the future water pressure at that loca-

tion. Another important aspect to be

considered when selecting the proper

maximum pressure is the allowable

hydraulic gradient of the rock mass. In

this: the higher is the hydraulic gradi-

ent the higher shall be the maximum

injection pressure.

In practice, the maximum pressure can

be set in a number of ways. The most

reliable method remains certainly the

execution of grout test sections on

site in the same conditions using the

proposed mix design. Another indirect

method is to conduct hydro-fracturing

tests in the pre-injection investigation

boreholes, and to apply a factor of

safety to the measured hydro-fracture

pressure. In contrast to grouting test

sections, for hydro-fracturing tests

there is no volume constraint for the

water, which is first of all risky. Sec-

ondly, acknowledging the difference in

water and grout mix, a careful evalu-

ation of the test results by an experi-

enced person is required to be able to

extract the desired information for the

actual admissible grouting pressures.

Alternatively, an estimation may be

made with the confining overburden

and surcharge pressure, or the limit

may even be set on an empirical basis

based upon previous experience in

similar rock conditions and/or depths

of injection.

It is important to recall that the GIN

technique is actually self-regulating.

Any possible adoption of the pressure

with depth to avoid grout outflow or

Figure 1. Typical examples of the evolution of the GIN value.