48

Geotechnical News • December 2015

THE GROUT LINE

additional boreholes do not neces-

sarily need to be drilled to full depth.

Instead, their optimum depth should

be selected based on the grout-

ing results of adjacent boreholes at

certain depth intervals. This simple

design consideration shows how, by

proper integration of the observational

method within the grouting procedure,

the full benefit of the self-adaptive

nature of the GIN concept can be

gained, thereby achieving a complete,

efficient, cost-effective, and safe

grouting job.

Acceptable final permeability

Before defining an acceptable final

permeability for a grouting job, one

should first think about what might

actually be the consequence of the

seepage and/or leakage caused by it.

There should be a clear differentiation

between seepage, which is defined

as interstitial movement of water in

the foundation, or the abutments,

and leakage, which is flow of water

through holes or cracks.

Taking a closer look, it quickly

becomes clear that foundation perme-

ability may directly affect the stability

of the structures to varying degrees,

mainly depending on the dam type and

height. Whilst for rock fill dams, for

example, a certain amount of leak-

age is common and is rather of little

relevance, for concrete dams, in par-

ticular if they are large, the same leaks

might already significantly impair

their safety.

This distinction was already recog-

nized by Lugeon in 1933, when he

came up with first indications for

allowable foundation permeabilities.

He suggested a limiting Lugeon value

of 3 for small dams and a Lu < 1 for

large dams, respectively. Based on

subsequent experience and critical

expert reviews, this concept has been

further refined over time, in particular

focusing on the actual warranty for

grouting. Today, engineers commonly

refer to the guidelines proposed by

Houlsby [3], which can be summa-

rized as indicated in Table 2. In the

same table also some typical ranges

for allowable hydraulic gradient allo-

cated to different dam types are given.

It is obvious that the highest hydraulic

gradients in the rock mass occur in the

contact zone at the dam foundation.

In the treated zone they diminish with

increasing distance from the dam rock

mass contact surface at the foundation.

Both, the recommended Lugeon and

typical allowable hydraulic gradients

as listed in Table 2 refer therefore to

the zone close to the dam rock mass

interface in the central foundation part.

With depth corresponding less strin-

gent values (i.e. higher Lugeon and

lower gradients) might be acceptable.

These values are obviously intended

for guidance only and their appropri-

ateness must be reviewed and veri-

fied individually for each project in

terms of the project-specific risks. To

arrive at an appropriate value, It is

important to identify the possibility of

encountering particular features and

peculiarities of the site by means of

thorough geological and hydrogeo-

logical investigations, and to evaluate

their influence on the permeability on

a short and long term. If permeability

and geological conditions on one site

are highly variable, certain generaliza-

tions are necessary.

Relevance of additional testing -

pre-injection and post-injection

The determination of permeabilities

is essential both to justify the need for

grouting, and to evaluate the success

of the works executed. Thus, water

pressure tests should be performed

in exploratory primary holes before

grouting and in check holes after com-

pletion of grouting in a certain section.

These tests are required to compare

the initial and the final permeabilities

of the rock mass and to assess in this

way the grout efficiency and success,

respectively.

On the other hand, the execution of

pre-injection water pressure tests in

individual grout stages during the

grouting programme, is not generally

necessary, and might negatively affect

the already treated rock mass. In addi-

tion, such tests during the injection

works may not be representative, since

there is no direct and/or consistent

relation between the penetration of

grout and that of water in a rock mass.

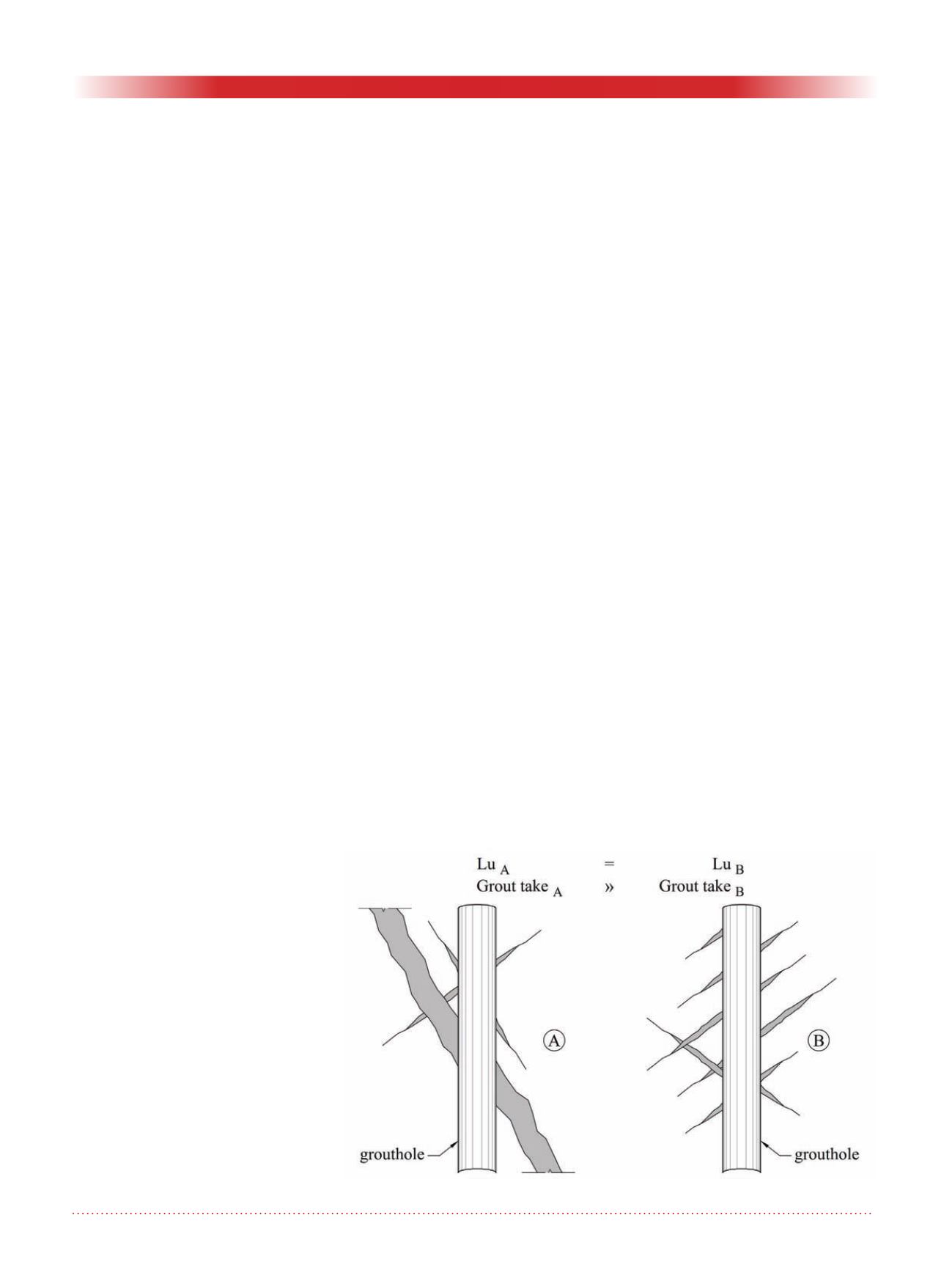

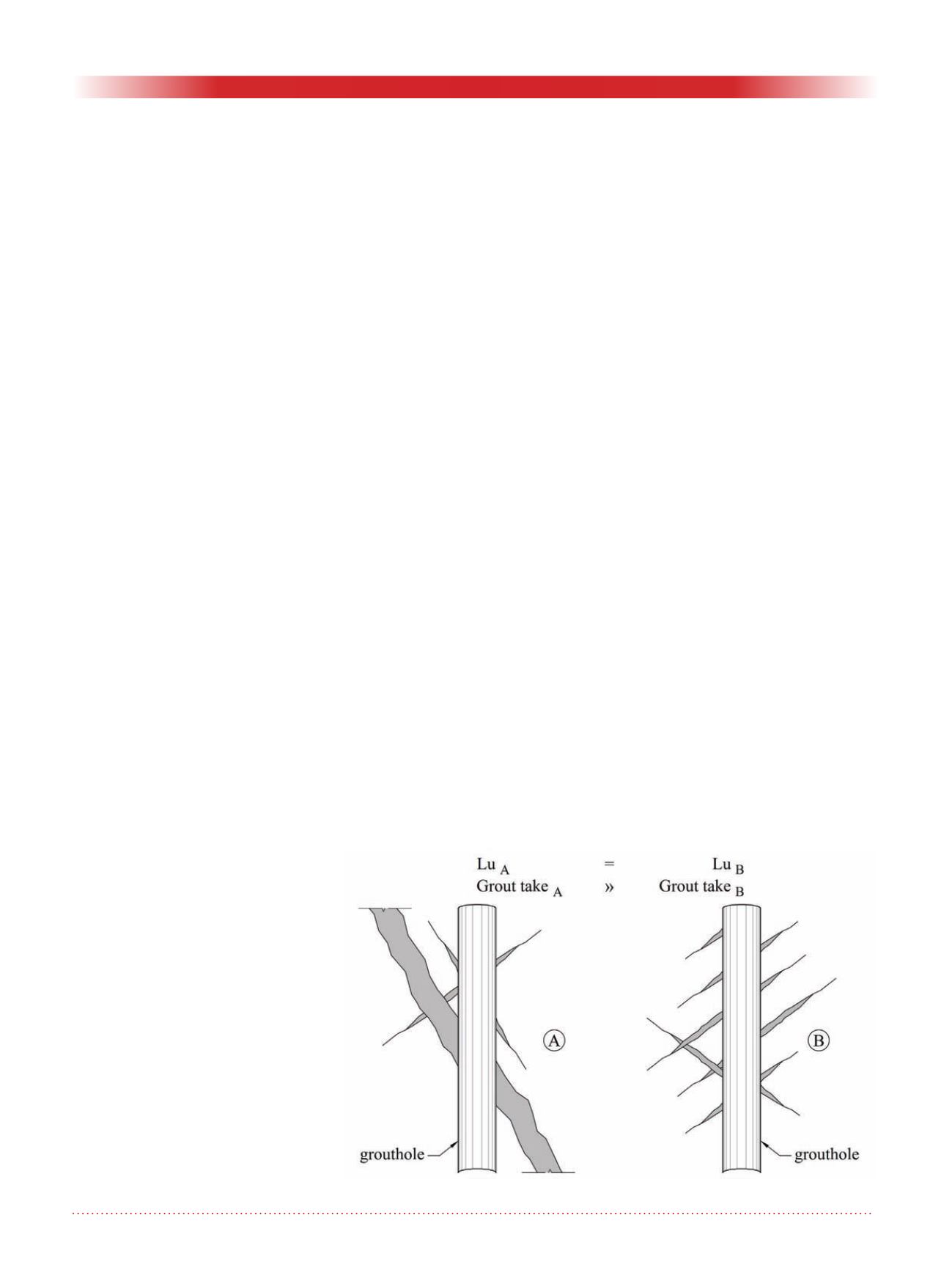

As shown in Figure 7, a unique wide

crack (A) may give the same Lugeon

value as a high frequency of fine joints

(B), while due to its binghamian rheol-

ogy as well as the maximum cement

grain size, the actual grout take might

be much lower in the latter case.

Figure 7. Difference in Lugeon values and grout takes for different fissures.