44

Geotechnical News • December 2015

THE GROUT LINE

ance of bleed within the voids and

fissures of the formation.

Stable mix

Generally a stable mix is a grout con-

sisting of a cement-based slurry, with

additives if necessary, to ensure that

no water is expelled from the suspen-

sion when injected at pressure (i.e. no

pressure-filtration). The stability of the

grout ensures that

• the grout rheological properties

remain constant throughout the

injection to maintain the fluidity

and penetration capability

• the progressively reducing ab-

sorption of grout can be clearly ob-

served, understood, and measured,

as the works progress

• no water filled zones are left

Consistent rheological properties

ensure a realistic comparison of grout

injection data between subsequent

phases of injection, and during the

course of a single injection.

This is why the mix should not be

fluidified with excess water. Water

should be mainly considered as trans-

port medium for cement grains not as

physical component of the mix.

Current practice is to employ a grout

of low water cement ratio (typically

0.6 -1.1), so that once an individual

injection is completed, the potential

for bleed in-situ is minimised. It

also ensures long-term strength and

durability reducing the requirement for

successive re-injections.

Single mix

For successful and efficient grouting,

it is highly recommended to inject a

single grout type with a consistent

water/cement ratio for all injections

and all phases of the works. Combined

with the stability of the grout, a single

mix enables the accurate verification

and control of the increasing compe-

tence and water-tightness of the strata

with the grouting works progress.

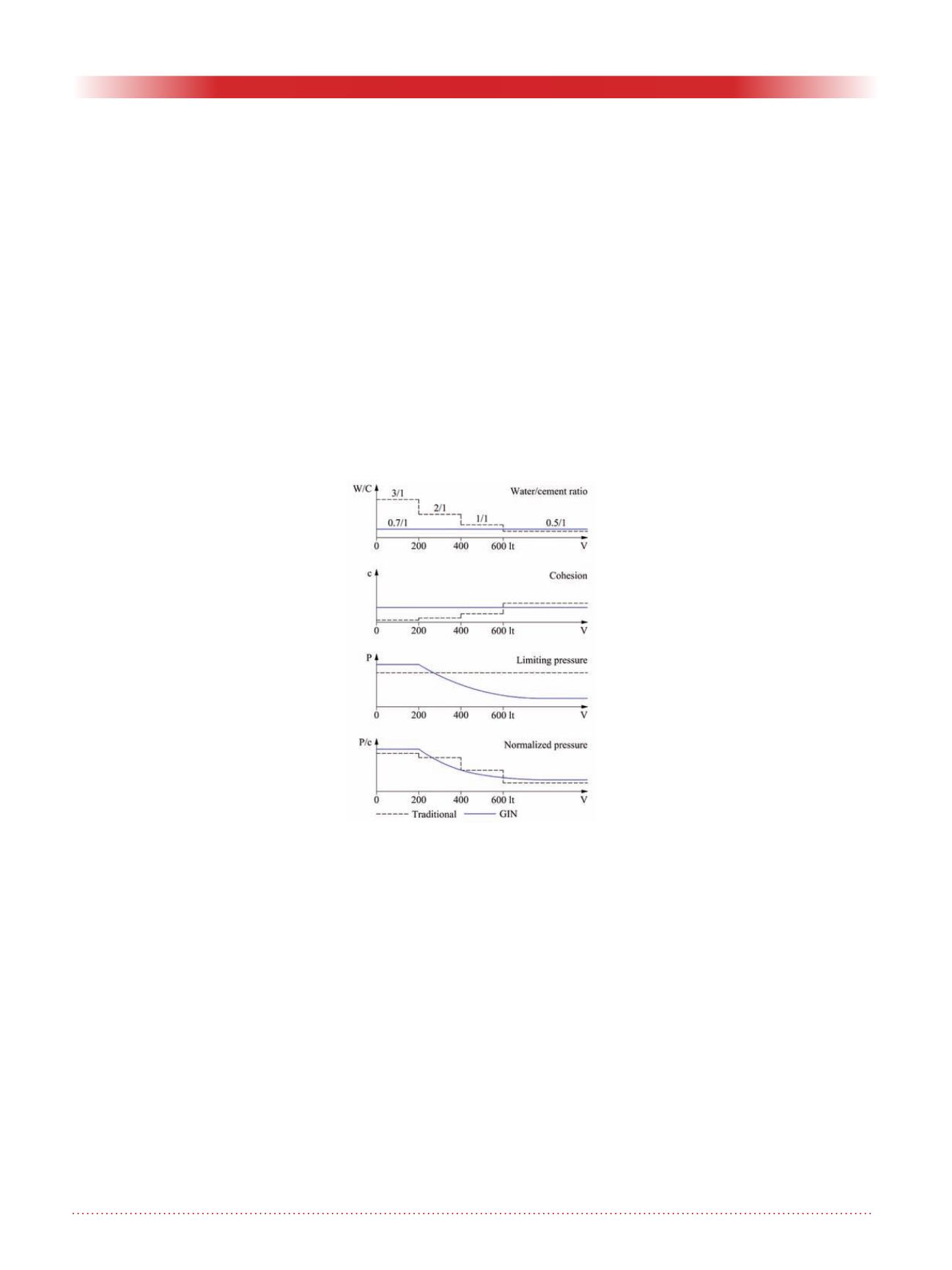

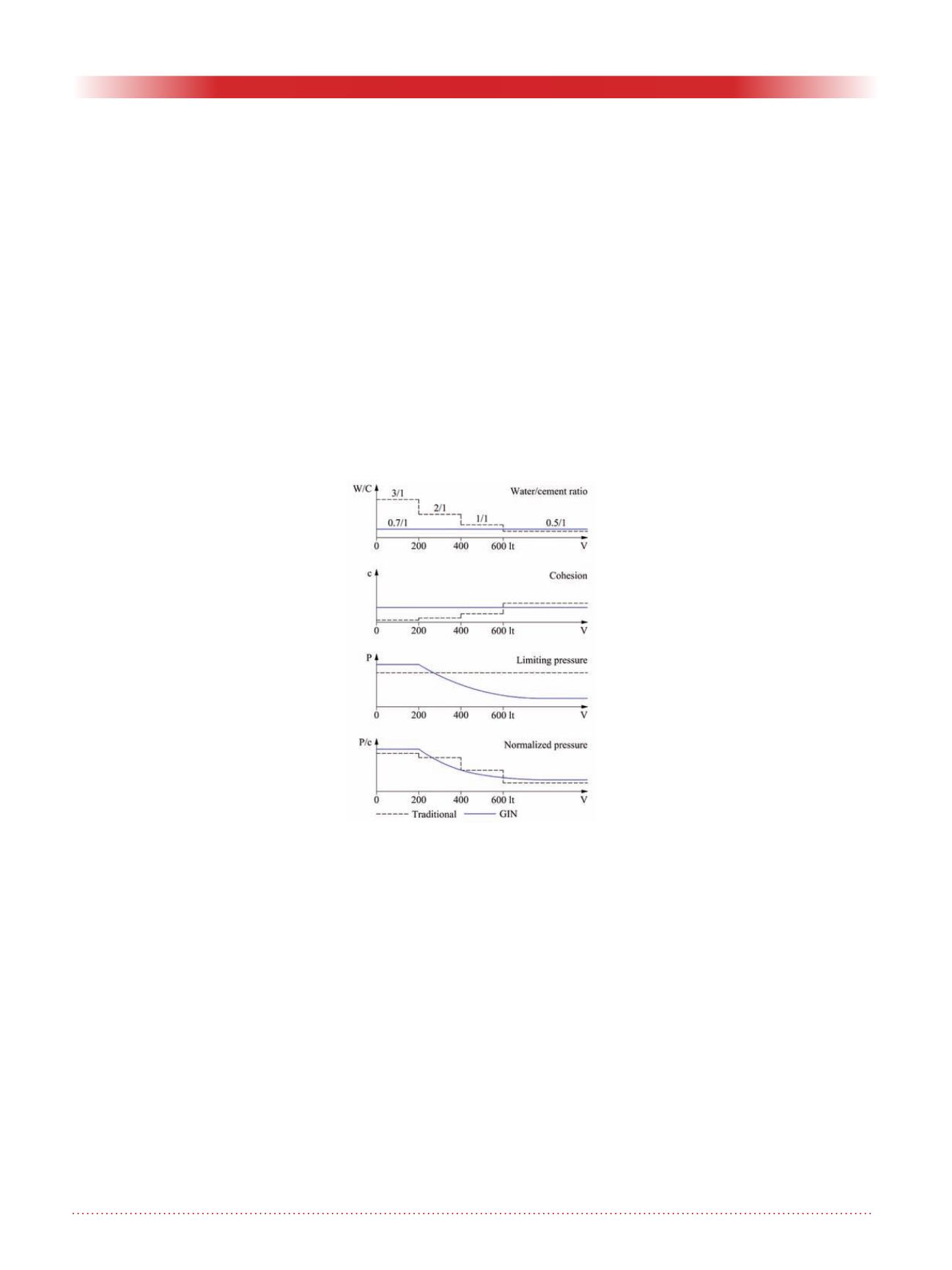

Recognizing the importance of using

a single mix is one of the main aspects

where the GIN approach differs from

classical grouting practice of 30 years

ago. Traditionally, the w/c ratio was

lowered in steps (see Figure 4) to

increase the cohesion, and in this way

lower the normalized pressure, P/c.

The introduction of the GIN concept

can be said to present a turning point

away from this traditional approach of

thickening the mixes in steps.

For GIN, (as indicated by the blue line

in Figure 4), it is recommended to

• Use 1 unique stable mix throughout

the grouting works

• Limit the grouting pressure with

increasing volume take

• Reduce the normalized pressure

(P/c) by progressively decreasing

the pressure.

The use of a single, stable, grout mix

avoids many potential errors in mix

formulation and in the interpreta-

tion of the most relevant injection

data - the volume per linear meter

injected. In the past, much effort has

been expended in trying to accurately

convert injected volumes into a dry

weight of material per linear metre

- a pointless exercise in terms of the

specified objectives and technical

management of the works, and only of

interest for assessing payment.

Multiple mixes, changed during a

single injection according to certain

volumetric or pressure criteria, have

resulted in a flawed understanding of

the grout absorption due to the fact

that insufficient consideration was

taken of the distance over which the

grout has been pumped, and/or the

volume of grout in the system. There

have been sites where mixes have

been changed in a rigid succession,

when one of the mixes in the sequence

has been still wholly or partly within

the delivery system, without ever

reaching the point of injection. Con-

sequently, the basis for changing the

grout mix was flawed, and a calcula-

tion of the total dry weight of material

injected into a grout stage at the time

of refusal was incorrect, so that deci-

sions on subsequent injections were

based on a false premise and under-

standing.

The changing of mixes, in particular

the thinning or thickening of the grout

mix already in the system, is prone to

errors of mix formulation and prepara-

tion, whether manually or automati-

cally batched, and this has led to errors

in calculating the effects of varying

viscosity and head loss, the extent

of pressure filtration and sedimenta-

tion, and hence in understanding the

effective penetration of grout into the

formation.

However, the real advantage of a

single mix is that it is designed specifi-

cally for the rock conditions on site,

and particularly for the finer fissures

required to be injected to achieve the

specified residual permeability,

Another real and valuable advantage is

to enable a simple and direct compari-

son of injections from stage to stage,

hole to hole, and between successive

phases of grouting. This is invaluable

in understanding and visualising in

real-time the improving condition of

the rock mass and reduction in mass

permeability.

Figure 4. Mix and pressure evolution

-Traditional versus GIN grouting.