Geotechnical News • December 2015

41

THE GROUT LINE

formed more cautiously, by applying

a lower grouting intensity. Table 1, as

a rough indication, shows the relation-

ship between some common GIN val-

ues, the grouting intensity scale, and

in accordance with the above, gives

a direct correlation with the geome-

chanical rock mass quality.

Thus,

Grouting intensity number, GIN

~ Rock mass quality

It is worthwhile noting that, in contrast

to many other fields of engineering,

the design of a grouting job strongly

depends on the rock mass - a natural

medium which is not designed by

ourselves. As consequence, there is

always an unavoidable uncertainty in

the definition of the generic mechani-

cal or hydraulic parameters, and the

engineer must be aware of this vari-

ability when using those parameters as

basis for the grouting design.

It frequently occurs that the actual

rock mass conditions do not cor-

respond to the ones anticipated and

assumed in the initial design phase. If

this discrepancy becomes significant,

it might indicate the need to change

the grouting intensity according to

the new findings. Optimally, the GIN

value for any given rock formation

should be chosen at the beginning

of the design procedure, and kept

constant for each phase, or for the

whole, grouting programme. For some

sites the GIN value might require to

be adjusted after the initial results are

analysed, and possibly even reviewed

further as the grouting works progress.

However, any abrupt and frequent

changes are to be avoided in order to

keep the control and analysis of the

grouting as simple as possible. Occa-

sional modifications might be neces-

sary, but should be always based on

a rational basis to avoid the grouting

becoming confusing and obscure. It

is noted that test grouting sections on

the site into the actual rock mass allow

to significantly reduce any possible

changes of the grouting design to a

minimum.

Apart from geological aspects, the

general project requirements and

grouting objectives should be care-

fully considered when establishing the

GIN value. For many applications, it is

possible to assign priorities to certain

zones, which are then treated using

higher grouting intensities.

Thus,

Grouting intensity number, GIN

~ Project requirements

Considering a grout curtain, for

example, after impounding of the

reservoir, a lower water pressure is

to be expected in the higher abut-

ments than in the central part of the

dam. Consequently, a lower grouting

intensity might be acceptable at higher

locations. A similar allocation can be

made for the constraints related to the

hydraulic gradient imposed by the

project. The hydraulic gradient in the

rock zone to be treated will highest

at a shallow depth and diminishes

quite fast while depth reaching its

minimum in the lowest point of the

curtain. Accounting for the fact that

in this lowest part the real efficiency

of the curtain is by definition zero, the

requirements for the grouting intensity

might actually also be defined less

stringent in this lower zone.

In this way unnecessary grouting in

zones of minor importance can be

avoided, while the main effort can be

focused on the most relevant zones.

This helps to significantly optimize the

whole grouting process.

Accordingly, the GIN number itself

incorporates both geological and

project design aspects. The intensity

is therefore directly related to the rock

mass quality as well as the relevance

of the grouting result for the project.

Once selected, the GIN value controls

the injection parameters within a safe

working envelope. However, the GIN

value needs to also reflect the con-

straints of the practicable values for

the minimum flow rate and minimum

controllable pressure of the grout

pump ( typically 200-300 l/ hr, and

approximately 2 bars ).

For any given grout type, and injec-

tion rate, the evolution of the GIN

value over the duration of the injection

will depend upon the rock conditions,

the grout rheology, and the injection

rate. Once the plot of P x V reaches

the boundary curve, the injection flow

rate, controlled by computer piloted

grout pumps, is progressively reduced

or increased automatically to maintain

the product P x V at or just below the

GIN curve until either the maximum

target volume is injected, or until

the flow rate reduces to a minimum

practicable level, at which point the

injection is complete.

When establishing a GIN value it is

therefore also necessary to consider

particularly the likely flow rate dur-

ing the latter stages of the injection,

(approaching the target volume) to

ensure that this is compatible with the

minimum practicable flow rate for the

grout pump, and grout gelling proper-

ties, to avoid line blockage.

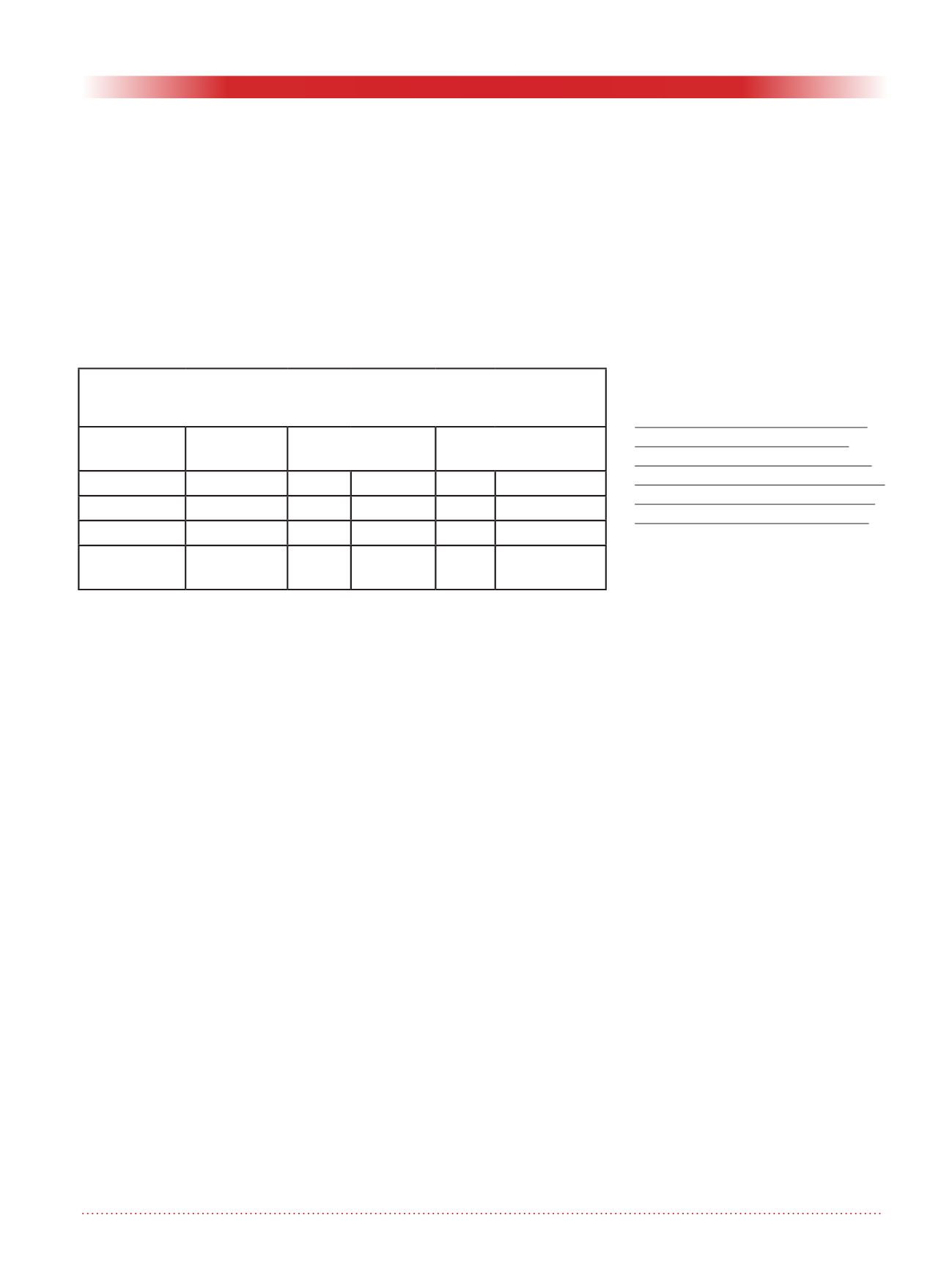

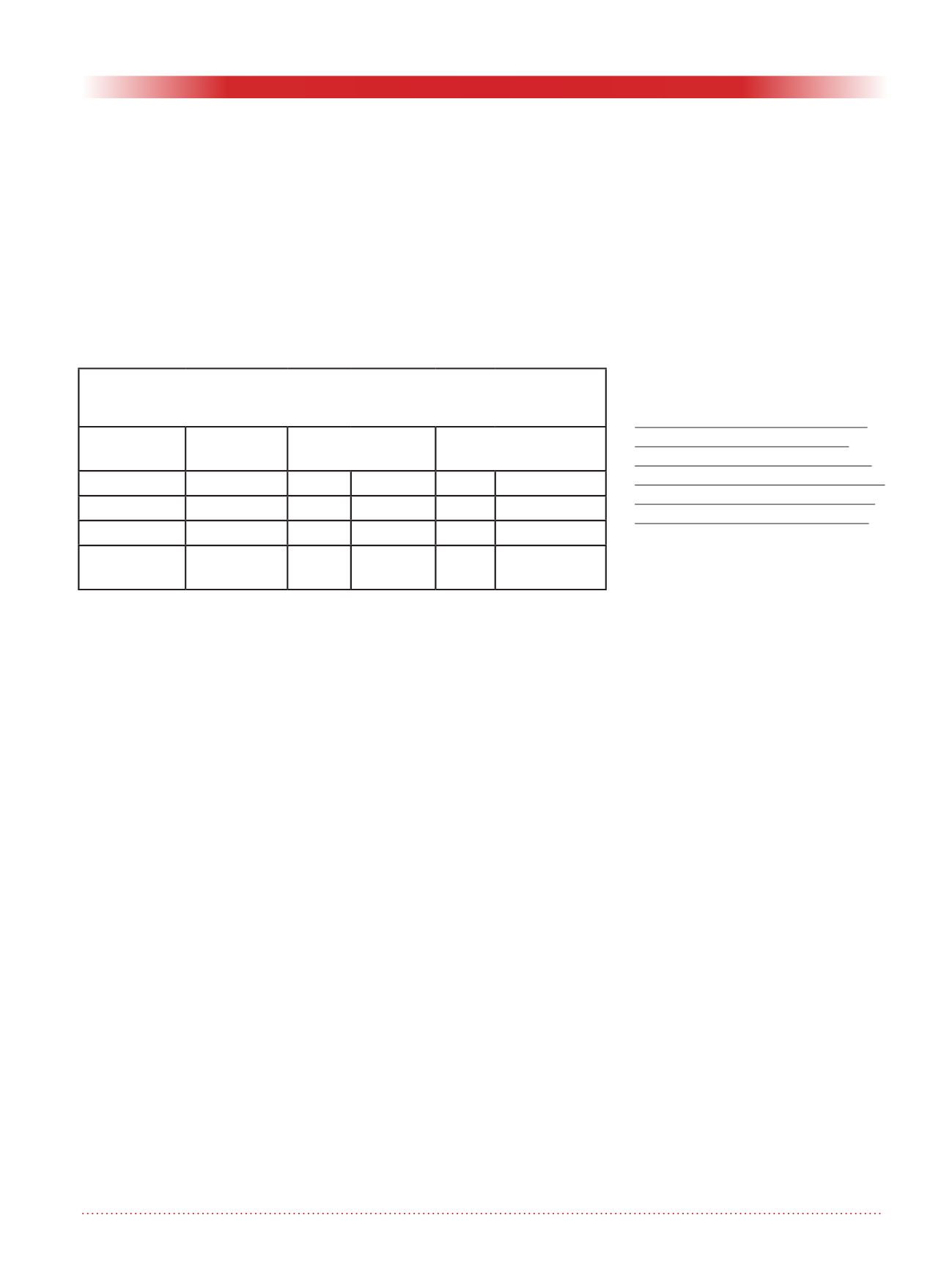

Table 1 GIN values with typically correlated geomechanical rock mass

quality ranges. Note: the indicated GIN values should be consistent with

the project requirements, and borehole location.

Intensity

GIN [bar.

litre/m]

RMR

RQD

Very high

> 2’500 81-100 very good 91-100 excellent

High

1’500 - 2’500 71-80 good

76-90 good

Moderate

1’000 - 1’500 41-70 fair - good 51-75 fair

Very low -

low

< 500 - 1’000 <40 very poor -

poor

<50 very poor -

poor