Geotechnical News • December 2015

47

THE GROUT LINE

Minimum flow rate

The minimum flow rate set for the

injection should be a pragmatic deci-

sion based upon the characteristics of

the pump, technical and cost efficiency

considerations, and understanding of

the gel and set times of the selected

grout, and especially upon examina-

tion of the GIN curve and the implied

injection pressures at the point on

the curve where the maximum target

volume has been placed. If, at the

maximum target volume, either the

minimum flow rate defined by the GIN

curve is below the minimum desirable

injection rate, or the injection pressure

is too low for accurate regulation then

the design GIN value may have to be

increased accordingly.

These considerations need to take

into account the experience of the

grouting engineer in similar rock

conditions and with the character-

istics of the equipment being used.

There is no technical or commercial

advantage in continuing the injection

to a point where any further minimal

improvement in the rock condition is

not justified by the cost of continuing

injection, or beyond the point at which

there is a risk of grout line blockage or

inefficient injection due to a change in

the rheology of the grout mix.

Successful completion of grouting

Decision for additional boreholes

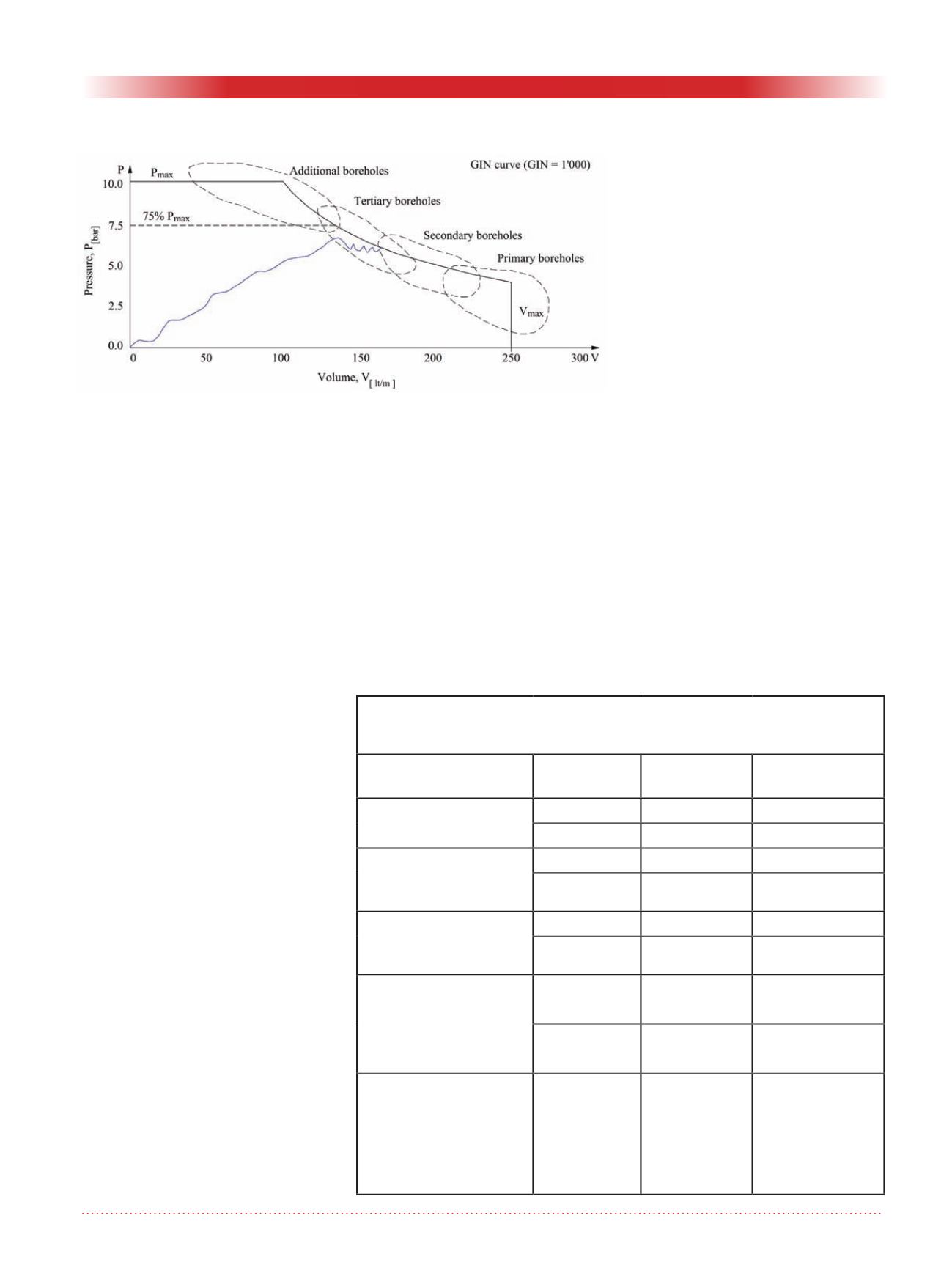

In accordance with the rock mass

conditions and project requirements,

grouting might be systematically

executed from primary or second-

ary boreholes, depending on the hole

spacing. The decision for additional,

i.e. tertiary or quaternary boreholes is

then based on the final grouting pres-

sure reached. According to the GIN

concept, and as a result of the split-

spacing borehole pattern, grouting is

a self-adaptive procedure: first wide

fissures are grouted at rather low pres-

sures, before by the following higher

order boreholes increasingly smaller

openings are filled using higher pres-

sures, as shown in Figure 6.

Consequently, when applying the GIN

technique, it can be observed that in

general the final grouting pressure

does continuously increase from phase

to phase, whilst the grout takes are

generally decreasing. This develop-

ment from the lower right to the upper

left of the GIN curve, reflects in fact

that for each phase the widest remain-

ing joints, not injected during previ-

ous phases, are filled. Such grouting

results are therefore considered much

more meaningful in terms of the actual

groutability than any water pressure

tests.

Generally, the grouting works are said

to be completed if the GIN curve is

reached at 50 to 75% of the final pres-

sure. If the grouting path intersects

the GIN curve at lower pressures,

for example as shown in Figure 16,

this phase cannot yet be considered

finished and additional boreholes

or phases are to be executed. These

Figure 6. Grouting development from stage to stage and decision criterion for

additional boreholes.

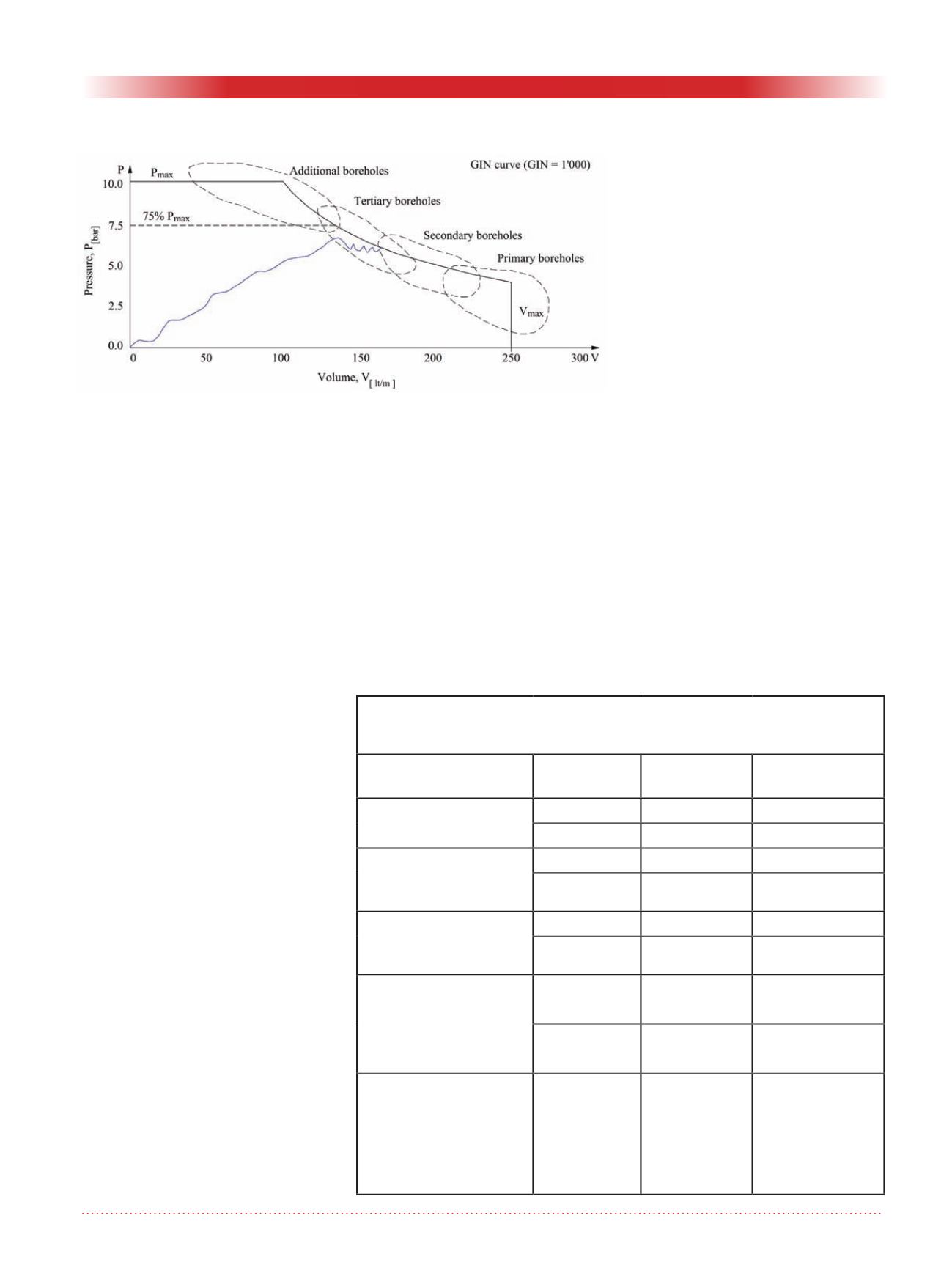

Table 2. Guidelines for acceptable foundation permeabilities, according

to Houlsby and ranges for typical allowable hydraulic gradients

allocated to different dam types.

Dam Type

Curtain Recommended

Lugeon

Typical allowable

hydr. gradient

Δ

Concrete Dams

Single row 3 - 5 Lu

5 - 10

Multiple row 5 - 7 Lu

1 - 5

Embankment dams with

narrow core (earth /

rockfill)

Single row 3 - 5 Lu

5 - 10

Multiple row 5 - 10 Lu

1 - 5

Embankment dams with

a wide core & membrane

faced dams

Single row 5 - 10 Lu

1 - 5

Multiple row 7 - 15 Lu

1 - 2

All dam types with foun-

dation material prone to

piping or wash-out by

seepage in general

Single row 3 - 5 Lu

5 - 10

multiple row 2 - 4 Lu

5

All dam types, if water

loss by seepage becomes

relevant for the project,

and thereby warrants

considerable expenditure

to stop it

Single and

multiple row

1 - 2 Lu

>25